SAF_5523451_09

22

MAINTENANCE

PRELIMINARY WARNINGS

All routine and extraordinary maintenance operations must be

carried out by qualied sta.

Before carrying out any work on the unit, be sure to disconnect

the power supply.

ROUTINE MAINTENANCE

Periodic maintenance is fundamental to keep the unit perfectly

ecient under a functional and energetic point of view.

A maintenance plan with yearly frequency is recommended,

stipulating the following operations and checks:

– The presence of air bubbles.

– Safety device eciency.

– Power supply voltage.

– Electrical absorption.

– Tightening of electrical and hydraulic connections.

– Circulation pump eciency.

TROUBLESHOOTING

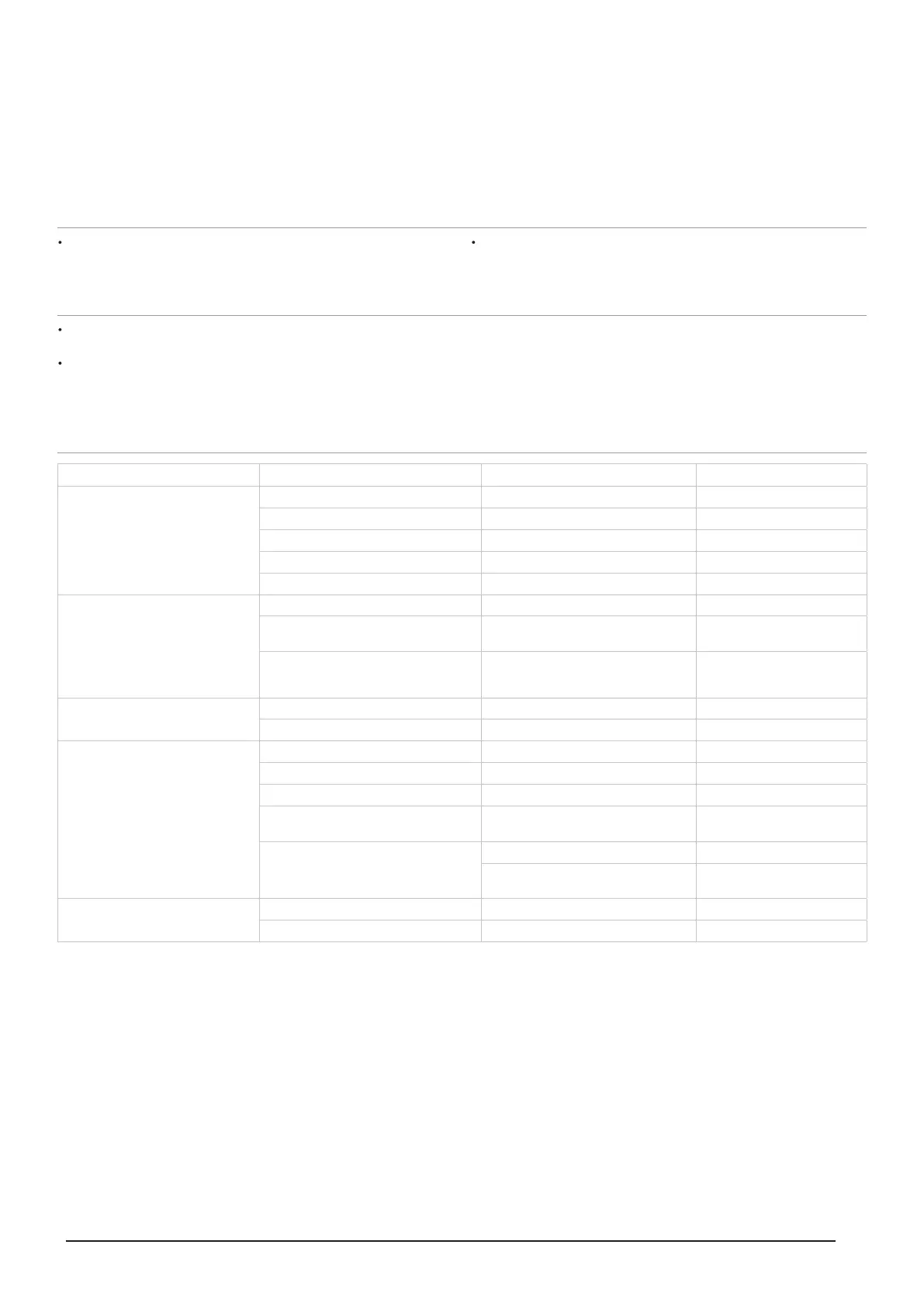

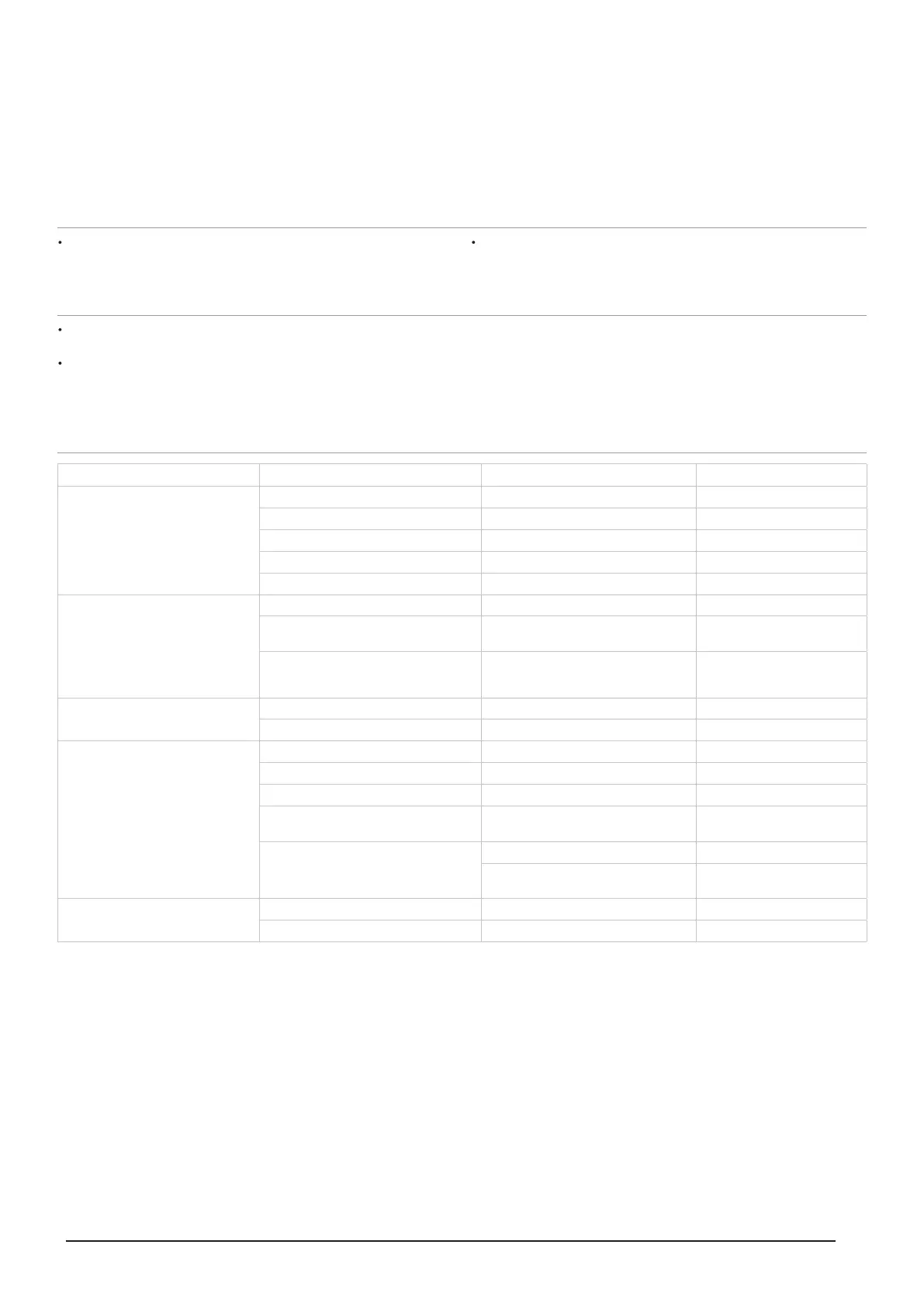

Anomaly Cause Solution U/I/A

The product will not start

No voltage Check the presence of voltage I

Master switch in OFF position Position to ON U

Control panel at OFF Position to ON U

Power supply voltage low Check power supply line I/A

Circulator failure Replace the component I/A

Insucient performance

Presence of air in the hydraulic system bleed I

Incorrect sizing of the equipment Check I

Operation outside of the operating

conditions recommended by the manu

-

facturer

Verify parameters I

Circulator noisy

Presence of air in the hydraulic system bleed i

Power supply voltage low Check power supply line I

The instant hot domestic water

producer stops because the protec

-

tions trip

Power supply voltage low Check I

Electric connections fastened badly Check I

Operation outside allowed limits Check I/A

Malfunction of probes or ow meter Replace the component I/A

Circuit breaker protection intervention

Check power supply voltage A

Check electric isolation of the circulator

windings

A

Elevated electrical absorption.

Non-compliant power supply voltage Check the power supply voltage I

Operation outside allowed limits Check I

Loading...

Loading...