70 Installation and First Startup

A Making Swagelok Connections

Making Swagelok Connections

Objective

To make a tubing connection that does not leak and that can

be taken apart without damaging the fitting.

Materials needed:

• 1/8- inch (or 1/4- inch, if used) preconditioned copper

tubing

• 1/8- inch (or 1/4- inch, if used) Swagelok nuts

• Front and back ferrules

• Two 7/16- inch (for 1/8- inch nuts) or 9/16- inch (for

1/4- inch nuts) wrenches

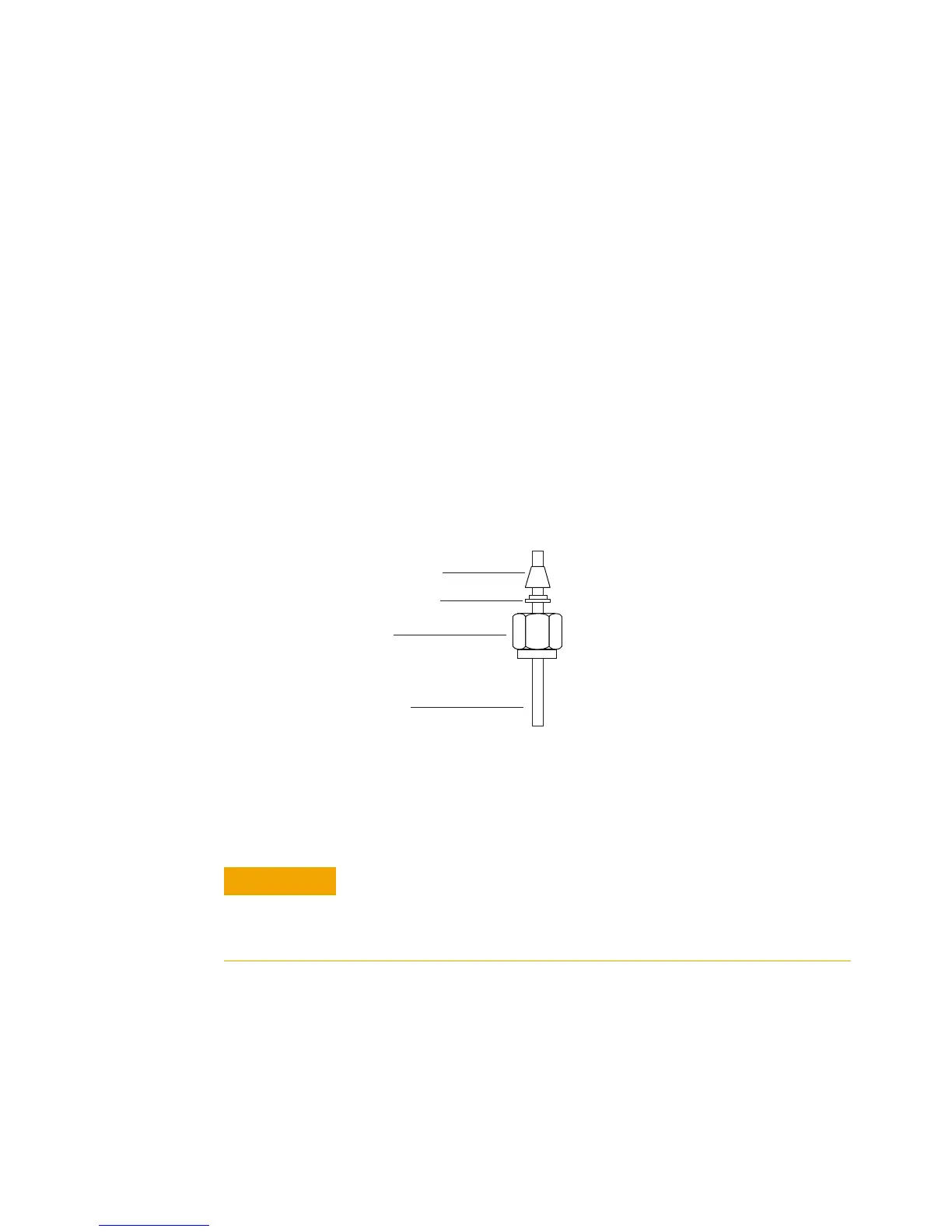

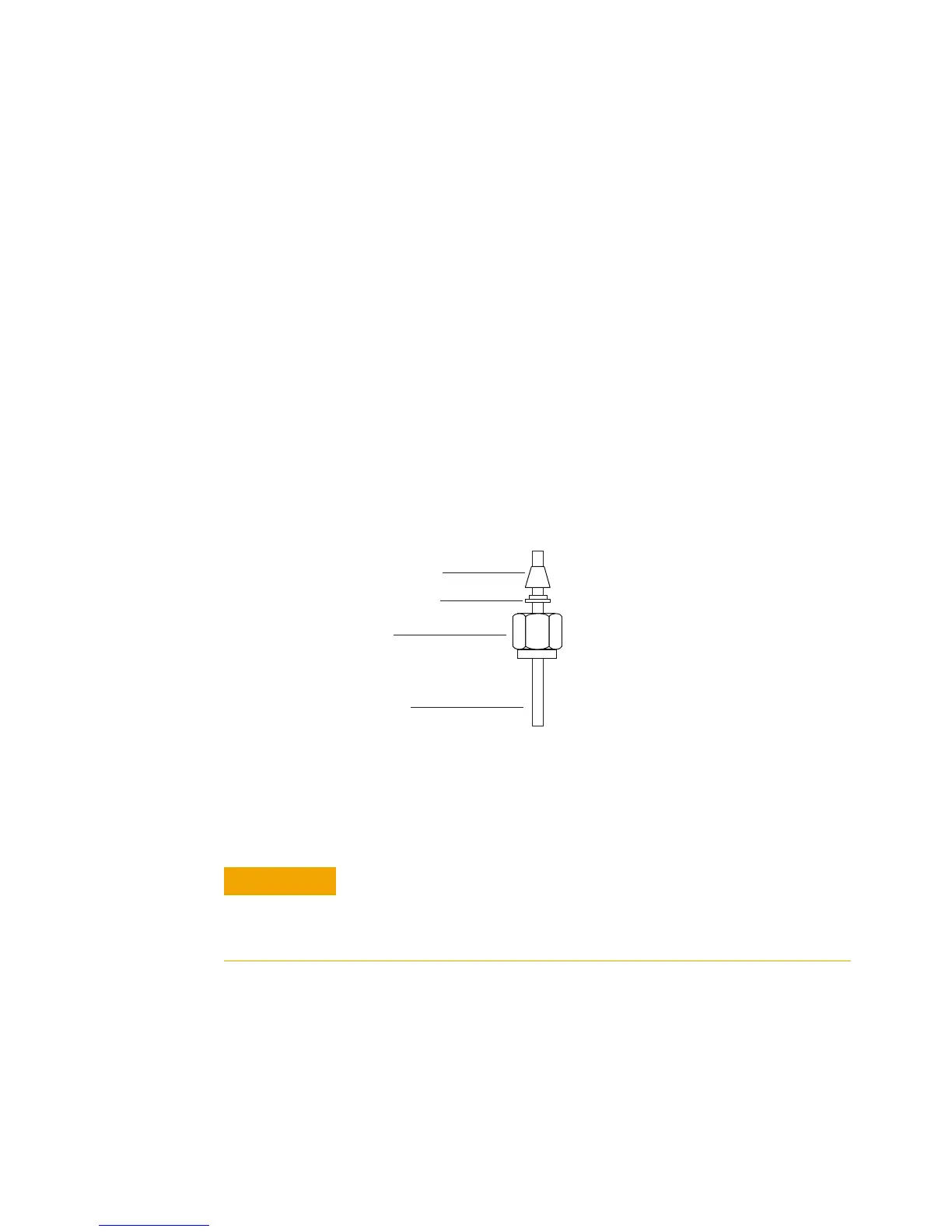

1 Place a Swagelok nut, back ferrule, and front ferrule to

the tubing as shown in Figure 25.

Figure 25 Swagelok nuts and ferrules

2 Clamp a stainless steel plug or similar fitting in a bench

vise.

3 Push the tubing into the stainless steel plug (see

Figure 26).

4 Make sure that the front ferrule is touching the plug.

Slide the Swagelok nut over the ferrule and thread it onto

the plug.

Front ferrule

Back ferrule

Nut

Tubing

Important!

The narrow end of the

back ferrule fits into

the rear of the front

ferrule.

Do not

Use a separate stainless steel fitting in a vise for initial tightening of

the nut. Do not use an inlet or detector fitting. Strong forces are

required to properly set the ferrules, and damage to an inlet or

detector fitting is very costly to repair.

Loading...

Loading...