Compressor

Compressor(s) are mounted on the base via the use of vibration isolators.

Each compressor is designed for use with R410A refrigerant.

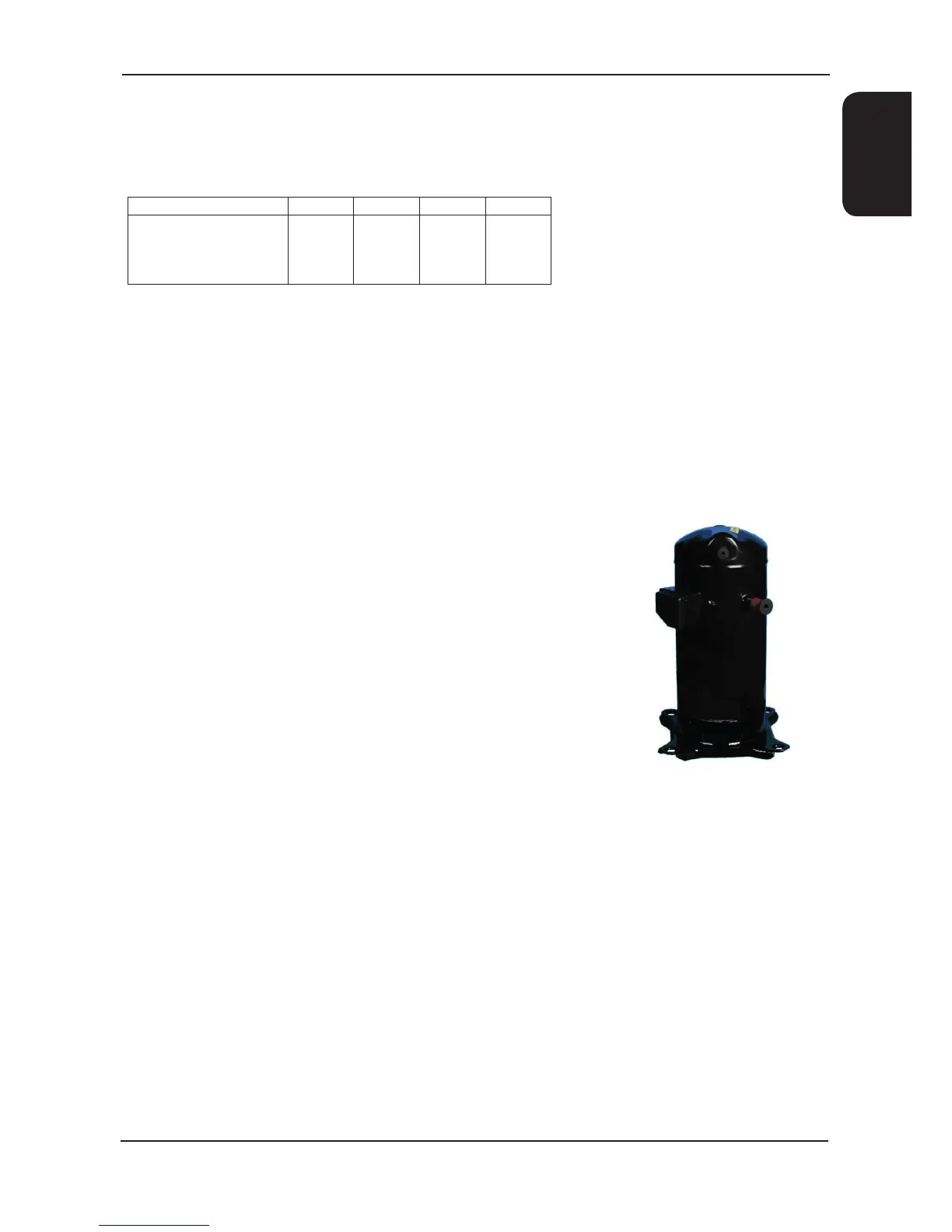

X X2 WX WX2

Thermal Protection

● ● ● ●

Single Compressor

● – ● –

Tandem Compressors

– ● – ●

●

Standard Feature ○ Optional Feature – Not Available

Tandem Compressors

Comprising of 2 scroll type compressors linked together by refrigerant pipework to

one common circuit.

Tandem compressors provide variable control of the system performance by

activating individual compressors as required. Multiple steps of unloading allow

external load demands to be met with greater precision, eliminating unnecessary

temperature and humidity variations. Consequently, system efciency and reliability

are much improved by extending major component working hours.

X and WX Models

Utilise a single hermetic scroll compressor tted as standard with:

• Thermal motor protection internal or external (dependent upon model size)

• High temperature discharge protection

X2 and WX2 Models

Utilise a tandem hermetic scroll compressor set, to provide 2 stages of control, tted

as standard with:

• Thermal motor protection internal or external (dependent upon model size)

• High temperature discharge protection

• Sight glass on common equalisation line.

Refrigeration

Each refrigeration circuit features as standard:

X Type

• Externally Equalised Thermostatic

Expansion Valve (TEV)

• Sight Glass

• Head Pressure Control

• Filter Drier

• Low Pressure Switch

• High pressure Switch

• Liquid Line Pressure Transducer

• Holding Charge of Inert Gas

WX Type

• Externally equalised thermostatic expansion valve (TEV)

• Sight Glass

• Head Pressure Control

• Filter Drier

• Low Pressure Switch

• High Pressure Switch

• Liquid Line Pressure Transducer

• Full operating charge of R410A

• Bleed valve

• Binder points

11

Loading...

Loading...