Process Control Instructions

142 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

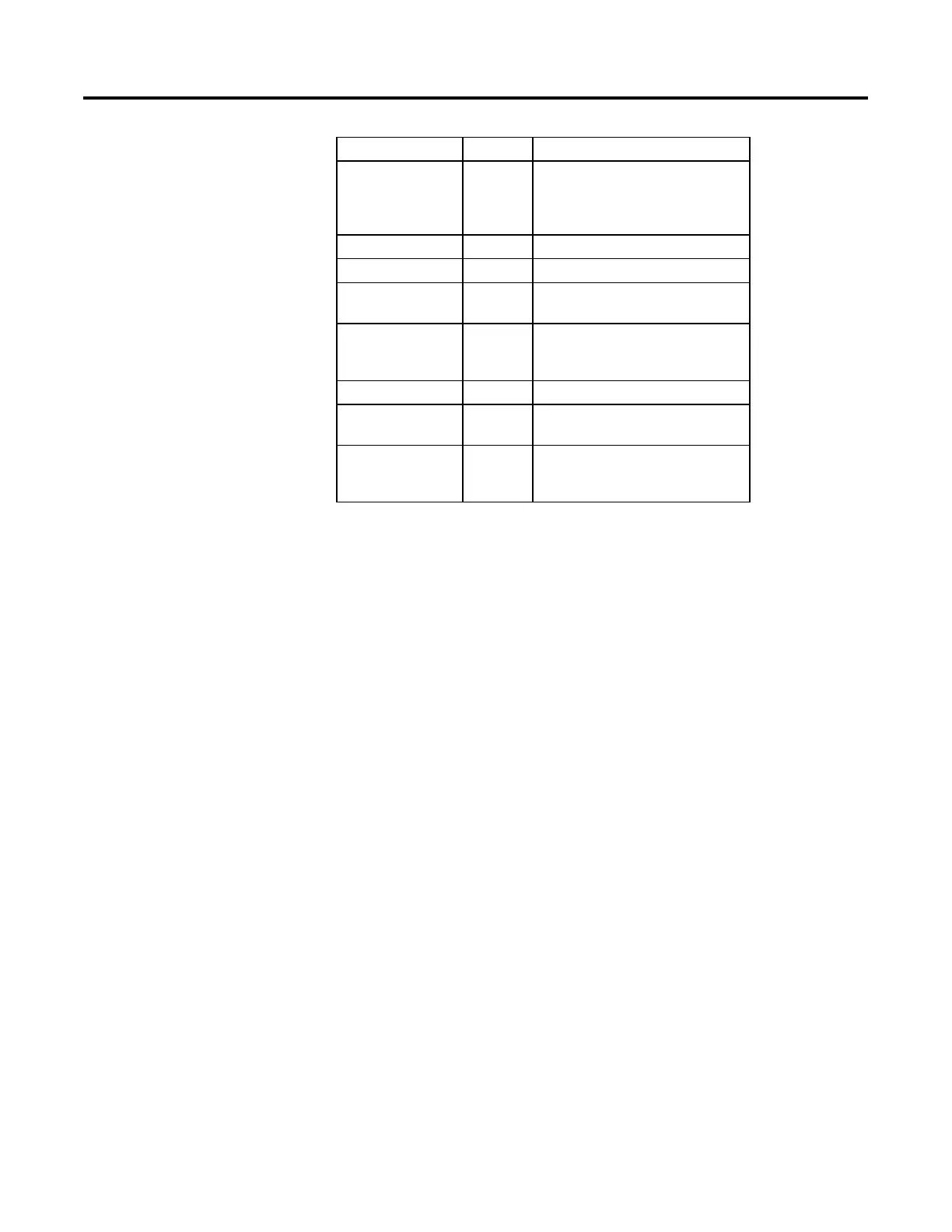

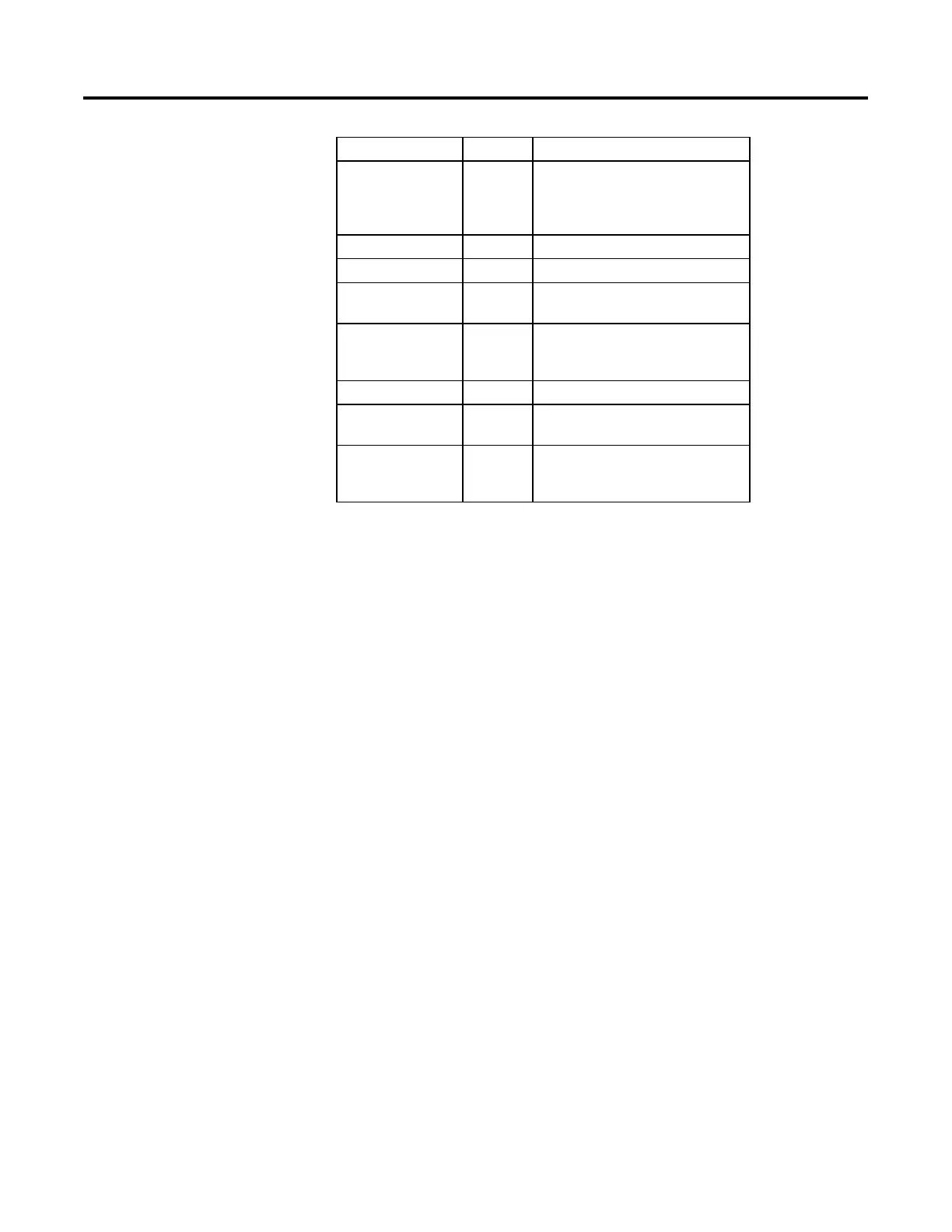

Status DINT Status of the function block.

InstructFault (Status.0) BOOL The instruction detected one of the following

execution errors. This is not a minor or major

controller error. Check the remaining status bits

to determine what occurred.

InFaulted (Status.1) BOOL In value faulted.

TimeBaseInv (Status.2) BOOL Invalid TimeBase value.

TimingModeInv

(Status.27)

BOOL Invalid TimingMode value.

RTSMissed (Status.28) BOOL Only used in real time sampling mode. Set to

true when

ABS(DeltaT – RTSTime) > 1 millisecond.

RTSTimeInv (Status.29) BOOL Invalid RTSTime value.

RTSTimeStampInv

(Status.30)

BOOL Invalid RTSTimeStamp value.

DeltaTInv (Status.31) BOOL Invalid DeltaT value. This can occur if

OversampleDT is invalid in oversample timing

mode.

Description

This instruction typically totals the amount of a material added over time, based

on a flow signal.

The TOT instruction supports:

• Time base selectable as seconds, minutes, hours, or days.

• You can specify a target value and up to two pre-target values. Pre-target

values are typically used to switch to a slower feed rate. Digital flags

announce the reaching of the target or pre-target values.

• A low flow input cutoff that you can use to eliminate negative totalization

due to slight flow meter calibration inaccuracies when the flow is shut off.

• Operator or program capability to start/stop/reset.

• A user defined reset value.

• Trapezoidal-rule numerical integration to improve accuracy.

• The internal totalization is done with double precision math to improve

accuracy.

Monitoring the TOT Instruction

There is an operator faceplate available for the TOT instruction.

Affects Math Status Flags

No

Loading...

Loading...