Function Block Attributes

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 499

2. The controller executes the other function blocks in the order determined

by how they are wired.

3. The controller writes outputs in OREFs.

These process control and drives instructions support different timing modes.

DEDT

LDLG

RLIM

HPF

NTCH

SOC

INTG

PI

TOT

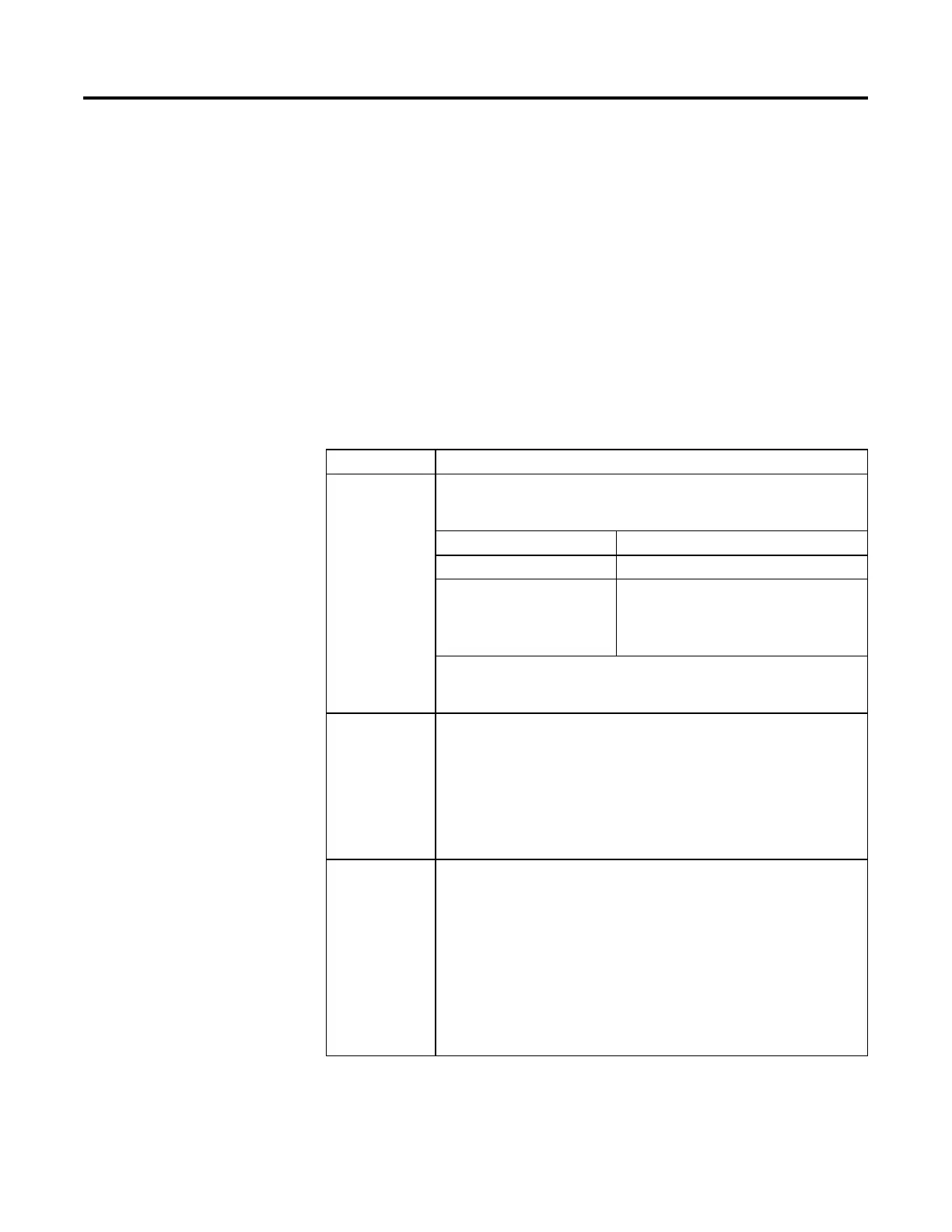

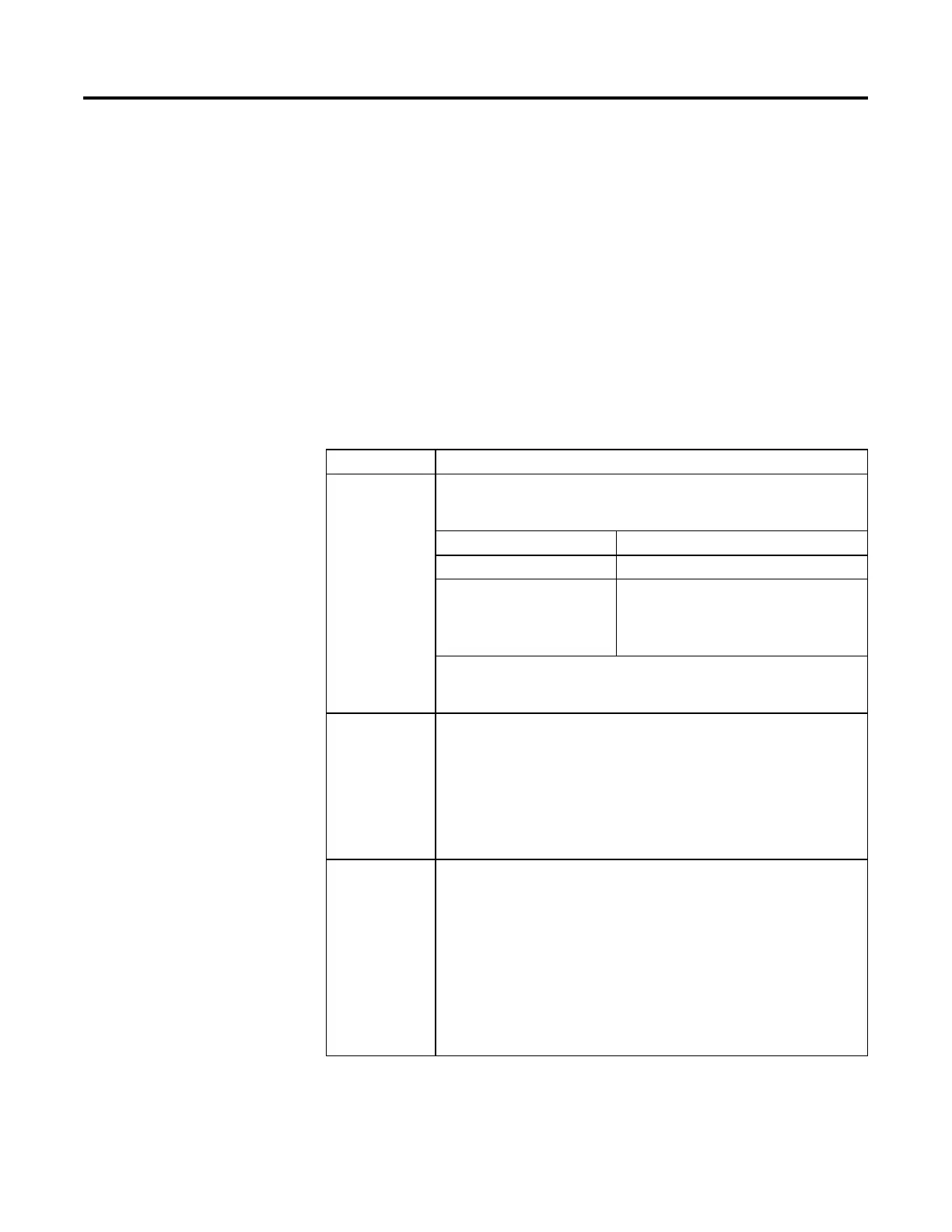

There are three different timing modes.

Timing Mode Description

Periodic Periodic mode is the default mode and is suitable for most control applications. We recommend

that you place the instructions that use this mode in a routine that executes in a periodic task. The

delta time (DeltaT) for the instruction is determined as follows:

If the instruction executes in a Then DeltaT equals

Periodic task Period of the task

Event or continuous task Elapsed time since the previous execution

The controller truncates the elapsed time to whole

milliseconds (ms). For example, if the elapsed time =

10.5 ms, the controller sets DeltaT = 10 ms.

The update of the process input needs to be synchronized with the execution of the task or

sampled 5-10 times faster than the task executes in order to minimize the sampling error between

the input and the instruction.

Oversample In oversample mode, the delta time (DeltaT) used by the instruction is the value written into the

OversampleDT parameter of the instruction. If the process input has a time stamp value, use the

real time sampling mode instead.

Add logic to your program to control when the instruction executes. For example, you can use a

timer set to the OversampleDeltaT value to control the execution by using the EnableIn input of

the instruction.

The process input needs to be sampled 5-10 times faster than the instruction is executed in order

to minimize the sampling error between the input and the instruction.

Real time sampling In the real time sampling mode, the delta time (DeltaT) used by the instruction is the difference

between two time stamp values that correspond to the updates of the process input. Use this

mode when the process input has a time stamp associated with its updates and you need precise

coordination.

The time stamp value is read from the tag name entered for the RTSTimeStamp parameter of the

instruction. Normally this tag name is a parameter on the input module associated with the

process input.

The instruction compares the configured RTSTime value (expected update period) against the

calculated DeltaT to determine if every update of the process input is being read by the instruction.

If DeltaT is not within 1 millisecond of the configuration time, the instruction sets the RTSMissed

status bit to indicate that a problem exists reading updates for the input on the module.

Time-based instructions require a constant value for DeltaT in order for the

control algorithm to properly calculate the process output. If DeltaT varies, a

Loading...

Loading...