Structured Text Programming

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 515

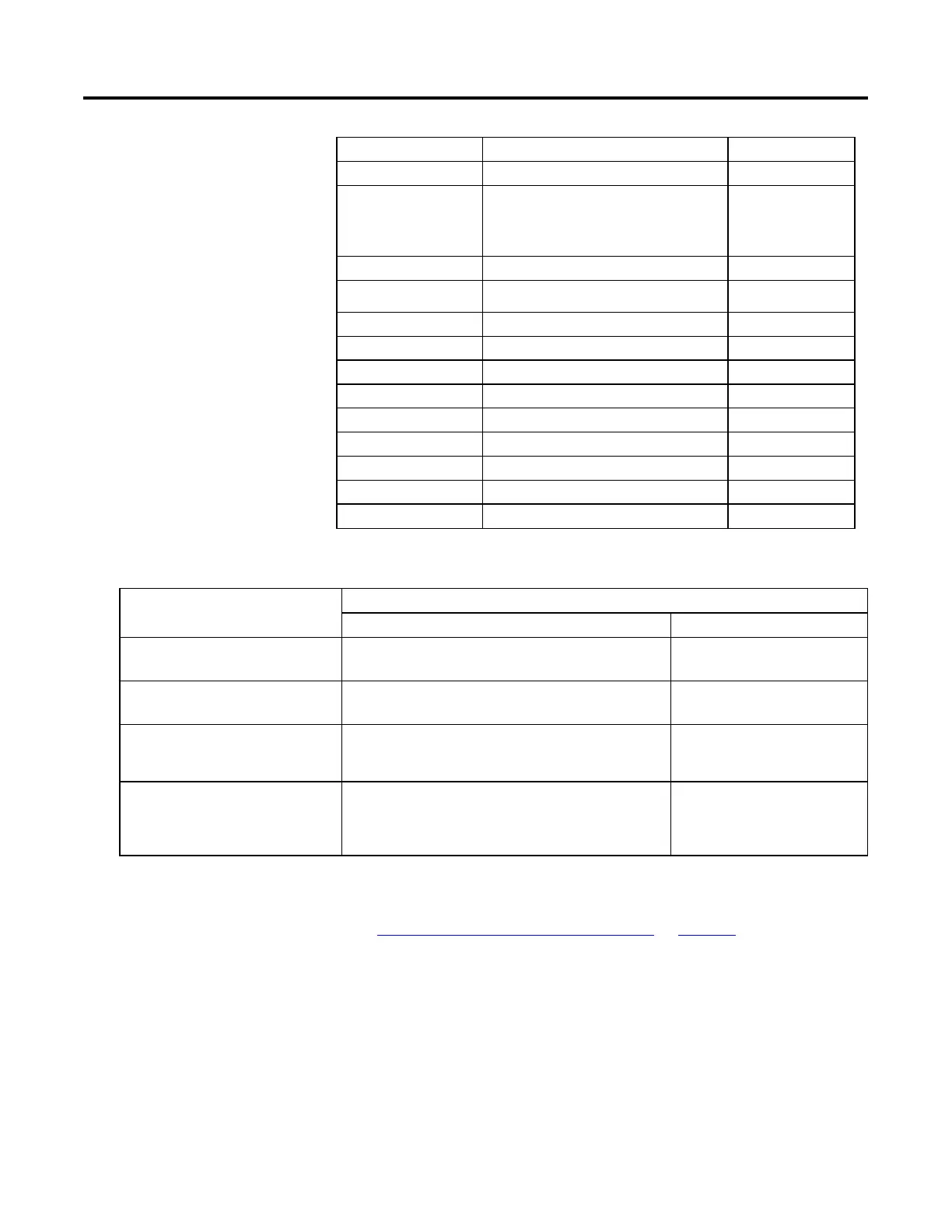

For Use this function Optimal data type

Absolute value ABS (numeric_expression) DINT, REAL

Arc cosine ACOS (numeric_expression) REAL

Arc sine ASIN (numeric_expression) REAL

Arc tangent ATAN (numeric_expression) REAL

Cosine COS (numeric_expression) REAL

Radians to degrees DEG (numeric_expression) DINT, REAL

Natural log LN (numeric_expression) REAL

Log base 10 LOG (numeric_expression) REAL

Degrees to radians RAD (numeric_expression) DINT, REAL

Sine SIN (numeric_expression) REAL

Square root SQRT (numeric_expression) DINT, REAL

Tangent TAN (numeric_expression) REAL

Truncate TRUNC (numeric_expression) DINT, REAL

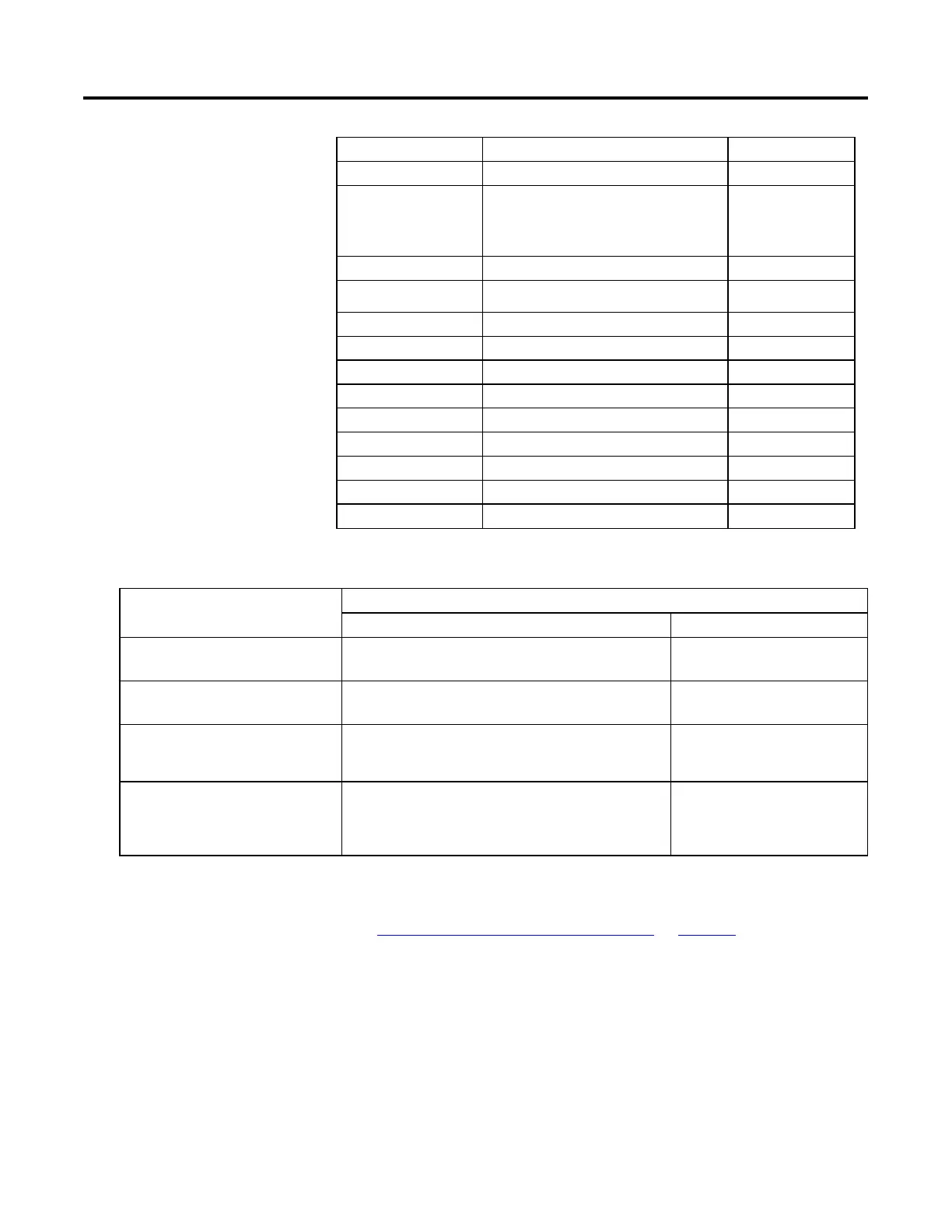

The table provides examples for using arithmetic operators and functions.

Use this format Example

For this situation Write

value1 operator value2 If gain_4 and gain_4_adj are DINT tags and your specification says:

‘Add 15 to gain_4 and store the result in gain_4_adj’"

gain_4_adj := gain_4+15;

operator value1 If alarm and high_alarm are DINT tags and your specification says:

‘Negate high_alarm and store the result in alarm.’

alarm:= -high_alarm;

function(numeric_expression) If overtravel and overtravel_POS are DINT tags and your specification says:

‘Calculate the absolute value of overtravel and store the result in

overtravel_POS.’

overtravel_POS := ABS(overtravel);

value1 operator (function((value2+value3)/2) If adjustment and position are DINT tags and sensor1 and sensor2 are

REAL tags and your specification says: ‘Find the absolute value of the

average of sensor1 and sensor2, add the adjustment, and store the result

in position.’

position := adjustment + ABS((sensor1 +

sensor2)/2);

See also

Structured Text Components: Expressions on page 513

Loading...

Loading...