Process Control Instructions

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 69

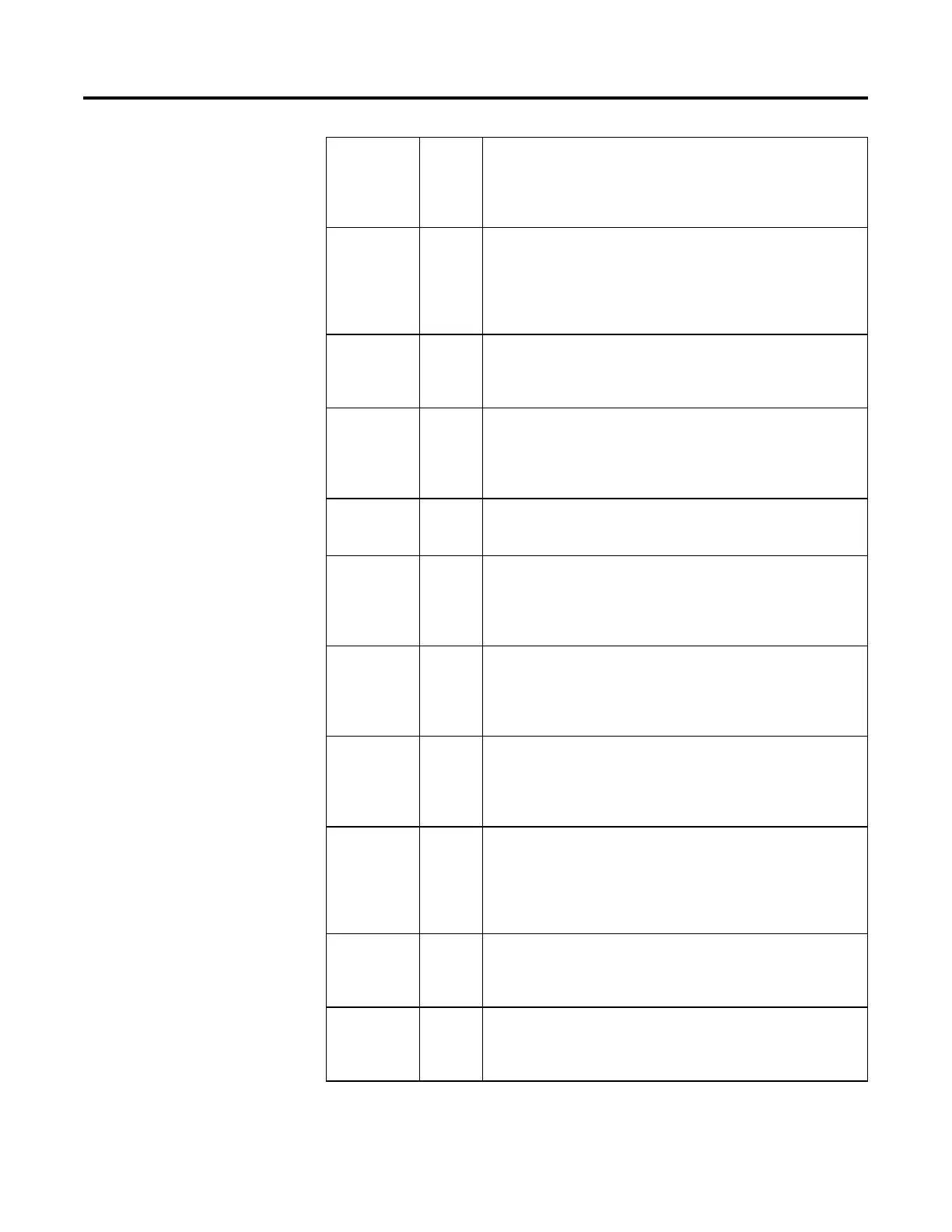

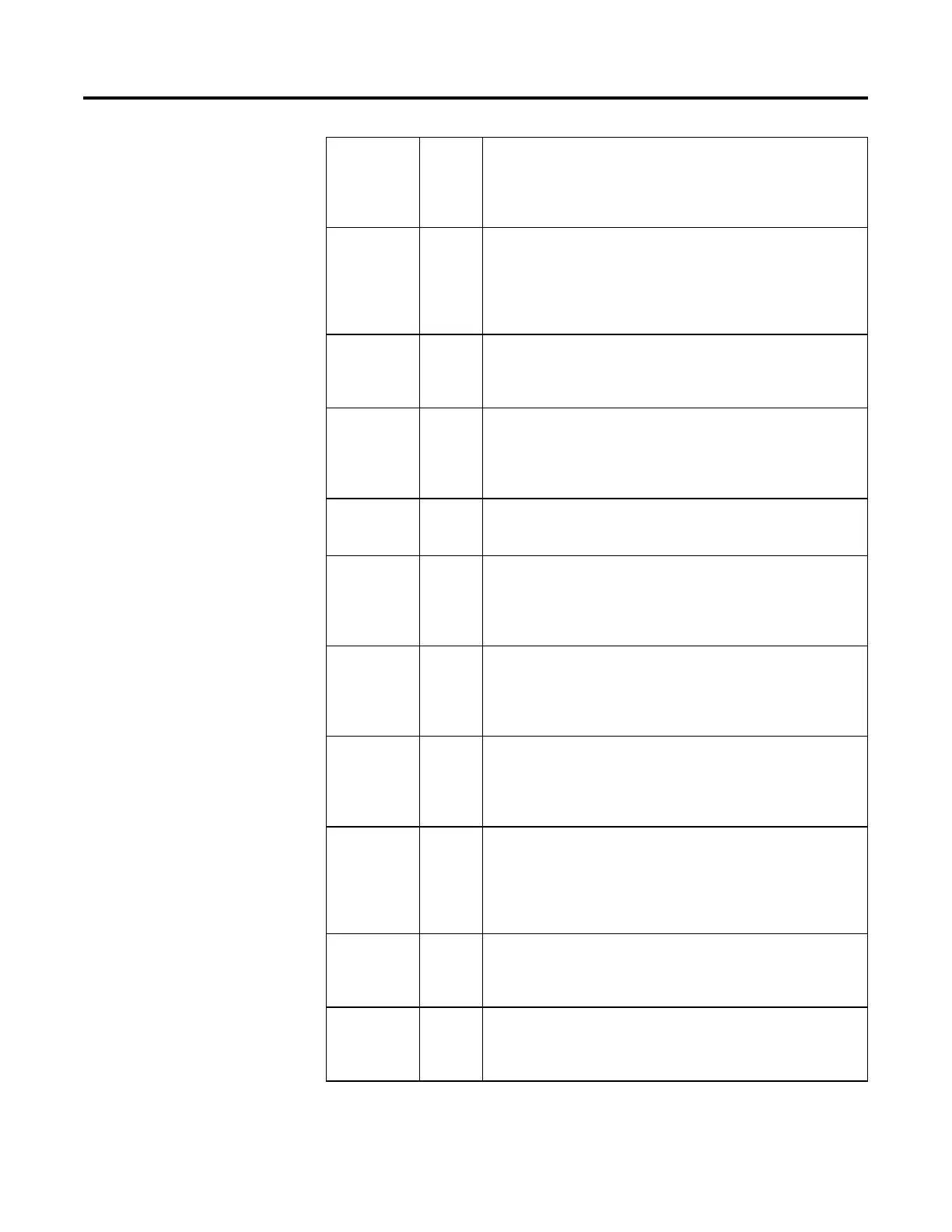

SPOper REAL SP operator value, scaled in PV units. SP is set to this value when in Operator control

and not Cascade/Ratio mode. If the value of SPOper < SPLLimit or > SPHLimit, the

instruction sets the appropriate bit in Status and limits the value used for SP.

Valid = SPLLimit to SPHLimit

Default = 0.0

SPCascade REAL SP Cascade value, scaled in PV units. If CascadeRatio is true and UseRatio is false, then

SP = SPCascade. This is typically the CVEU of a primary loop. If CascadeRatio and

UseRatio are true, then SP = (SPCascade x Ratio). If the value of SPCascade < SPLLimit

or > SPHLimit, set the appropriate bit in Status and limit the value used for SP.

Valid = SPLLimit to SPHLimit

Default = 0.0

SPHLimit REAL SP high limit value, scaled in PV units. If SPHLimit > PVEUMax, the instruction sets the

appropriate bit in Status.

Valid = SPLLimit to PVEUMax

Default = 100.0

SPLLimit REAL SP low limit value, scaled in PV units. If SPLLimit < PVEUMin, the instruction sets the

appropriate bit in Status. If SPHLimit < SPLLimit, the instruction sets the appropriate

bit in Status and limits SP using the value of SPLLimit.

Valid = PVEUMin to SPHLimit

Default = 0.0

UseRatio BOOL Allow ratio control permissive. Set to true to enable ratio control when in Cascade/Ratio

mode.

Default is false.

RatioProg REAL Ratio program multiplier. Ratio and RatioOper are set equal to this value when in

Program control. If RatioProg < RatioLLimit or > RatioHLimit, the instruction sets the

appropriate bit in Status and limits the value used for Ratio.

Valid = RatioLLimit to RatioHLimit

Default = 1.0

RatioOper REAL Ratio operator multiplier. Ratio is set equal to this value when in Operator control. If

RatioOper < RatioLLimit or > RatioHLimit, the instruction sets the appropriate bit in

Status and limits the value used for Ratio.

Valid = RatioLLimit to RatioHLimit

Default = 1.0

RatioHLimit REAL

Ratio high limit value. Limits the value of Ratio obtained from RatioProg or RatioOper. If

RatioHLimit < RatioLLimit, the instruction sets the appropriate bit in Status and limits

Ratio using the value of RatioLLimit.

Valid = RatioLLimit to maximum positive float

Default = 1.0

RatioLLimit REAL Ratio low limit value. Limits the value of Ratio obtained from RatioProg or RatioOper. If

RatioLLimit < 0, the instruction sets the appropriate bit in Status and limits the value to

zero. If RatioHLimit < RatioLLimit, the instruction sets the appropriate bit in Status and

limits Ratio using the value of RatioLLimit.

Valid = 0.0 to RatioHLimit

Default = 1.0

CVFault BOOL Control variable bad health indicator. If CVEU controls an analog output, then CVFault

normally comes from the analog output’s fault status. When true, CVFault indicates an

error on the output module and the instruction sets the appropriate bit in Status.

Default is false = "good health"

CVInitReq BOOL CV initialization request. This signal is normally controlled by the "In Hold" status on

the analog output module controlled by CVEU or from the InitPrimary output of a

secondary PID loop.

Default is false.

Loading...

Loading...