Process Control Instructions

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 77

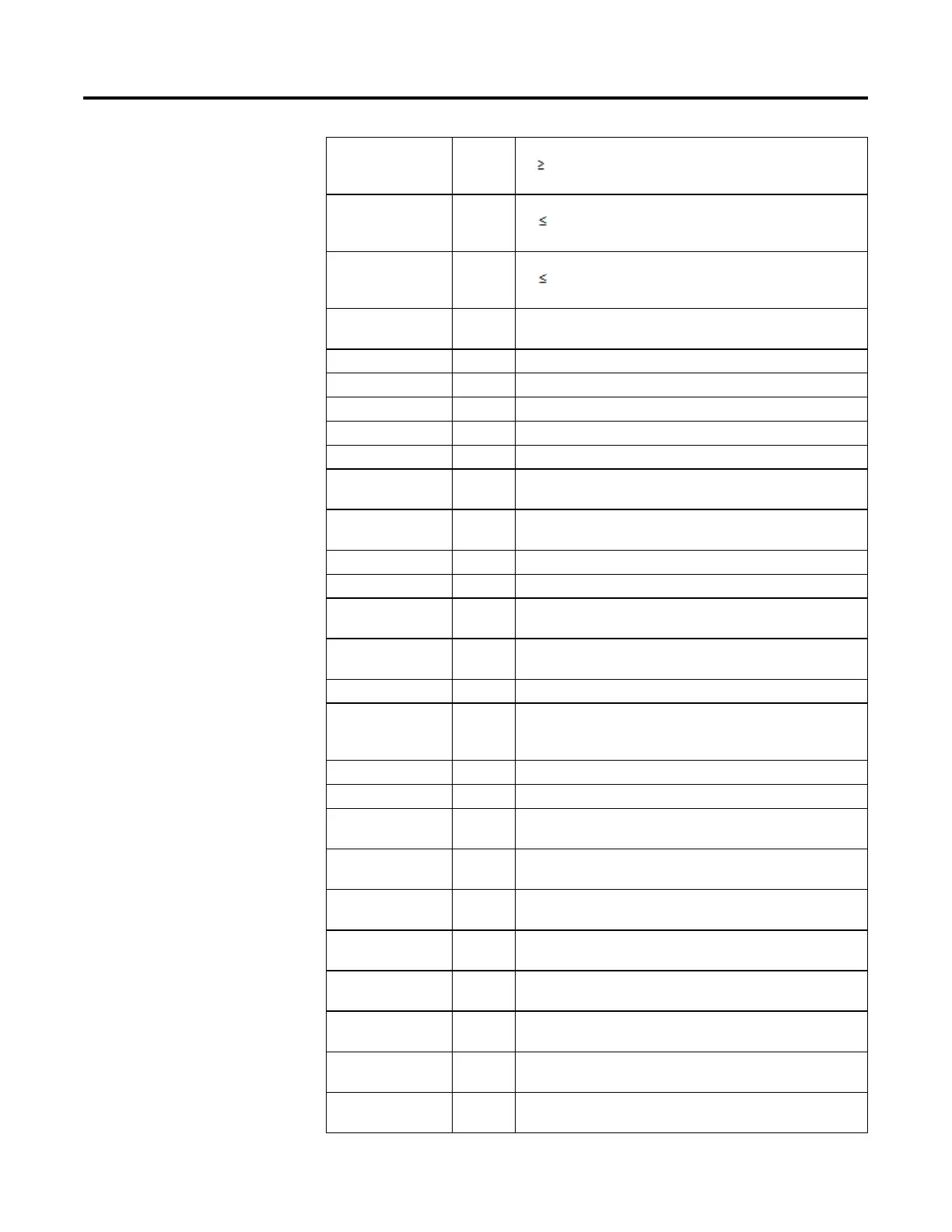

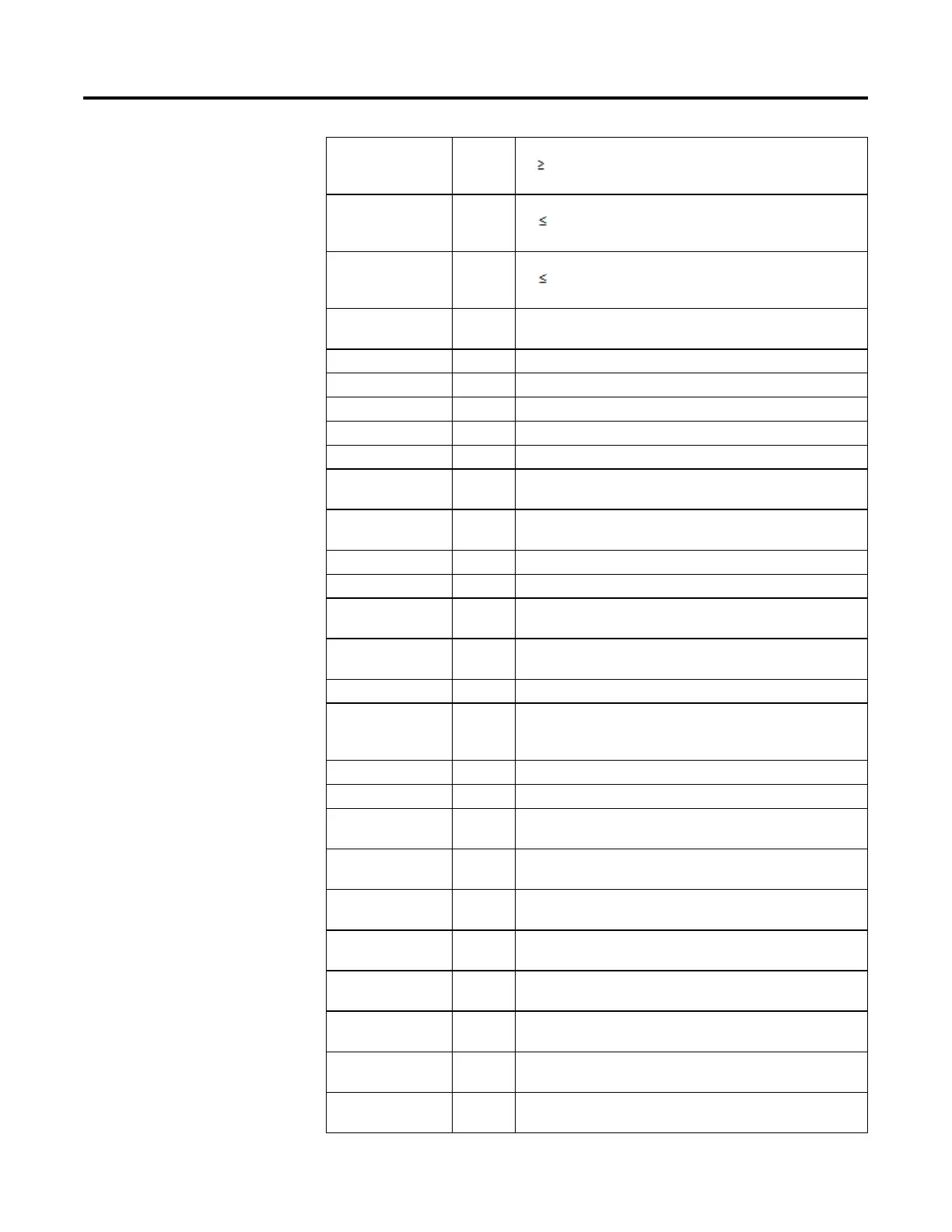

DevHAlarm BOOL Deviation high alarm indicator. Set to true when

PV (SP + DevHLimit). Cleared to false when

PV < (SP + DevHLimit - DevDeadband)

DevLAlarm BOOL Deviation low alarm indicator. Set to true when

PV (SP - DevLLimit). Cleared to false when

PV > (SP - DevLLimit + DevDeadband)

DevLLAlarm BOOL Deviation low-low alarm indicator. Set to true when

PV (SP - DevLLLimit). Cleared to false when

PV > (SP - DevLLLimit + DevDeadband)

ProgOper BOOL Program/operator control indicator. Set to true when in Program control.

Cleared to false when in Operator control.

CasRat BOOL Cascade/ratio mode indicator. Set to true when in the Cascade/Ratio mode.

Auto BOOL Auto mode indicator. Set to true when in the Auto mode.

Manual BOOL Manual mode indicator. Set to true when in the Manual mode.

Override BOOL Override mode indicator. Set to true when in the Override mode.

Hand BOOL Hand mode indicator. Set to true when in the Hand mode.

DeltaT REAL Elapsed time between updates. This is the elapsed time in seconds used by the

control algorithm to calculate the process output.

AtuneReady BOOL Set to true when the specified AtuneData has been acquired by the PIDE

instruction.

AtuneOn BOOL Set to true when auto tuning has been initiated.

AtuneDone BOOL Set to true when auto tuning has completed.

AtuneAborted BOOL Set to true when auto tuning has been aborted by the user or due to errors that

occurred during the auto tuning operation.

AtuneBusy BOOL Set to true when the specified AtuneData could not be acquired because it is

currently acquired by another PIDE instruction.

Status1 DINT Status of the function block.

InstructFault

(Status1.0)

BOOL The instruction detected one of the following execution errors. This is not a

minor or major controller error. Check the remaining status bits to determine

what occurred.

PVFaulted (Status1.1) BOOL Process variable (PV) health bad.

CVFaulted (Status1.2) BOOL Control variable (CV) health bad.

HandFBFaulted

(Status1.3)

BOOL HandFB value health bad.

PVSpanInv

(Status1.4)

BOOL Invalid span of PV. PVEUMax £ PVEUMin.

SPProgInv

(Status1.5)

BOOL SPProg < SPLLimit or SPProg > SPHLimit. The instruction uses the limited value

for SP.

SPOperInv

(Status1.6)

BOOL SPOper < SPLLimit or SPOper > SPHLimit. The instruction uses the limited

value for SP.

SPCascadeInv

(Status1.7)

BOOL SPCascade < SPLLimit or SPCascade > SPHLimit. The instruction uses the

limited value for SP.

SPLimitsInv

(Status1.8)

BOOL Limits invalid: SPLLimit < PVEUMin, SPHLimit > PVEUMax, or SPHLimit <

SPLLimit. If SPHLimit < SPLLimit, the instruction limits the value using SPLLimit

RatioProgInv

(Status1.9)

BOOL RatioProg < RatioLLimit or RatioProg > RatioHLimit. The instruction limits the

value for Ratio.

RatioOperInv

(Status1.10)

BOOL RatioOper < RatioLLimit or RatioOper > RatioHLimit. The instruction limits the

value for Ratio.

Loading...

Loading...