Transport, stor age and disposal

4 Transport, storage and disposal

4.1 Transport

For weight specifications (→ documents for the particular

order).

4.1.1 Unpacking and inspection on delivery

1. Unpack the pump/aggregate on delivery and inspect it for

transport damage.

2. Report any transport damage to the manufacturer immedi-

ately.

3. Dispose of packaging material according to local regula-

tions.

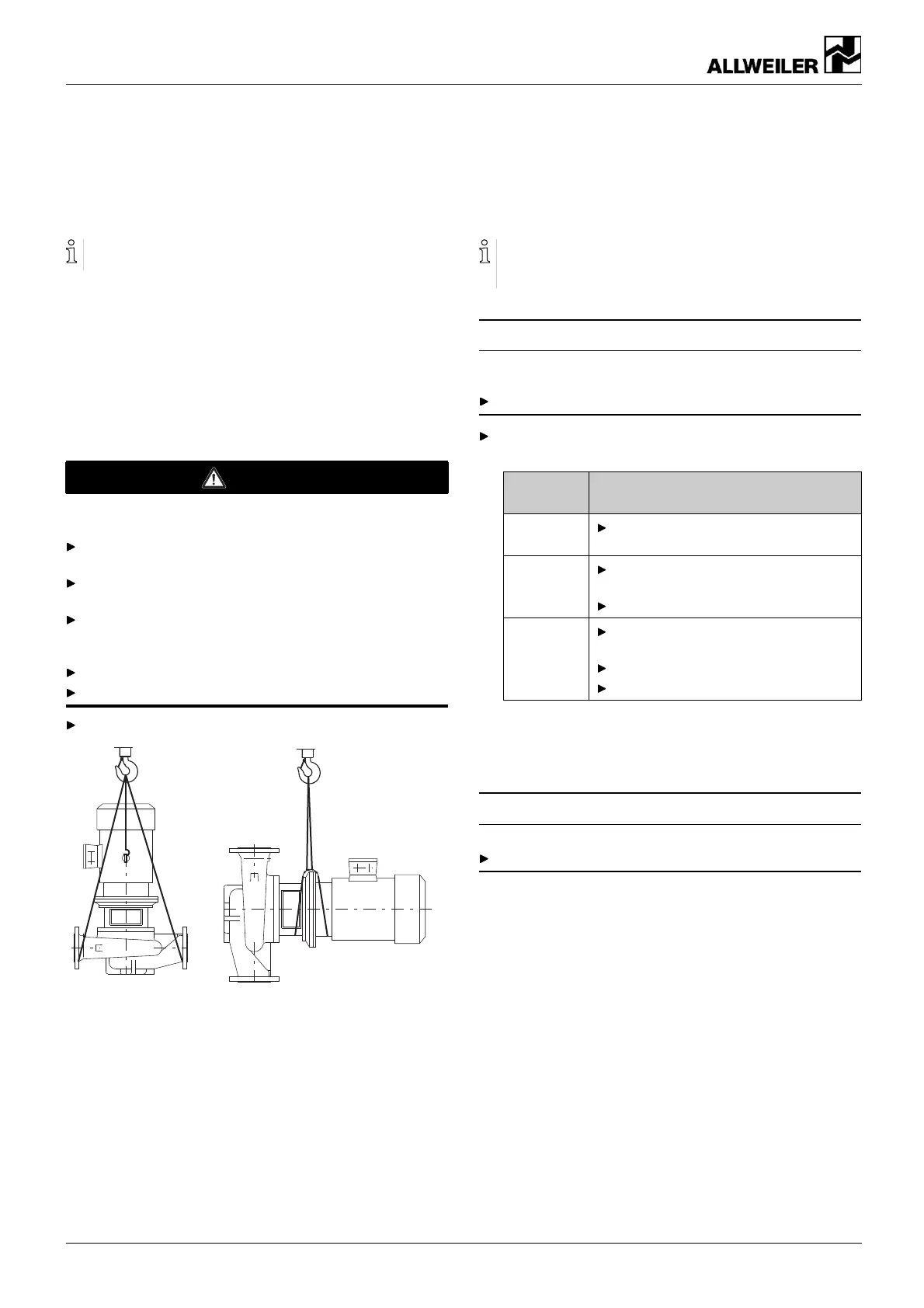

4.1.2 Lifting

DANGER

Death or crushing of limbs caused by falling or overturning

loads!

Use lifting gear appropriate for the total weight to be trans-

ported.

Fasten the lifting gear as shown in the foll owing illustra-

tions.

Never fasten the lifting gear onto t he motor eyebolt (unless

used as a safety device against tipping over for units with

ahighcenterofgravity).

Do not stand under suspended loads.

Set the load down on a level surface.

Lift the pump/unit properly.

Fig. 6 Fasten ing the lifting gear to the pump aggregate

4.2 Preservation

Not necessary for n on-rusting materials.

Contact the manufacturer for r ecommendations regarding

preservatives.

NOTE

Material damage due to inappropriate treatment for stor-

age!

Treat the pump properly, inside and outside, for storage.

Preserving pump (observe the processi ng specifications of

the manufacture rs)

Duration

[months]

Measures

Up to 6 All bare meta l parts should be tre ated,

inside and outside.

6–12 All bare meta l parts should be tre ated,

inside and outside.

Shrink-wrap the pump in plastic film.

12 – 24 All bare meta l parts should be tre ated,

inside and outside.

Shrink-wrap the pump in plastic film.

Use VCI anticorrosive.

Tab. 7 Treatment for storage

4.3 Storage

NOTE

Material damage due to inappropriate storage!

Treat and store the pump properly.

1. Seal all openings with blind flanges, blind plugs or plastic

covers.

2. Make sure the storage room meets the following condi-

tions:

–Dry

– Frost-free

– Vibration-free

3. Turn the shaft once a month.

4. Make sure the shaft and bearing change their rotational

position in the process.

5. Every 6 months:

– Renew the preservative if necessary.

12 NIT series BA-2017.03 en-U S 160-282/ 0 – 550 154

Loading...

Loading...