Operation

6 Operation

For pumps in explosion hazard areas ( → ATEX additional

instructions).

6.1 Preparations for the initial start-up

6.1.1 Identifying the pump type

Identify the pump type (→ order data sheet).

The pump types vary e.g. with regard to the shaft seal,

auxiliary systems.

6.1.2 Removing the preservative

Only necessary for pumps treated with preservative

(→ 4.4 Removing the preservative, Page 13).

6.1.3 Preparing auxiliary systems (if available)

The man ufacturer does not accept any liability for damage

arising from the installation or use of a third-party or unap-

proved auxiliary system.

Sealing systems

1. Verify that the sealing medium is suitable to mix (i.e. com-

patible) with the pumped medium.

2. Identify the sealing system:

–(→ order data sheet)

–(→ 3.4.1 Sealing systems, Page 11).

3. Install the sealing system (→ manufacturer's specifica-

tions).

4. Make sure the parameters require d for the installed sealin g

system are met (→ 9.2.3 Parameters for auxiliary syste ms,

Page 36).

5. Ensure that the permissible container pr essure is not

exceeded on blocking pressure systems (→ manufac-

turer's specifications).

6.1.4 Filling and bleeding

Auxiliary systems ready for operation

WARNING

Risk of injury and poisoning due to hazardous pumped

media!

Safely collect any leaking pumped m edium and dispo se

of it in accordance with environmental rules and require-

ments.

NOTE

Material damage caused by dry running!

Make sure the pump is filled properly.

Filling and venting the pump

1. Fill the pump and the s uction pipe with pumped medium.

2. Open the suction-side armature.

3. Open the pressure-side armature.

4. If present: open the auxiliary systems and check the flow

rate.

5. Verify that no pipe connections are leaking.

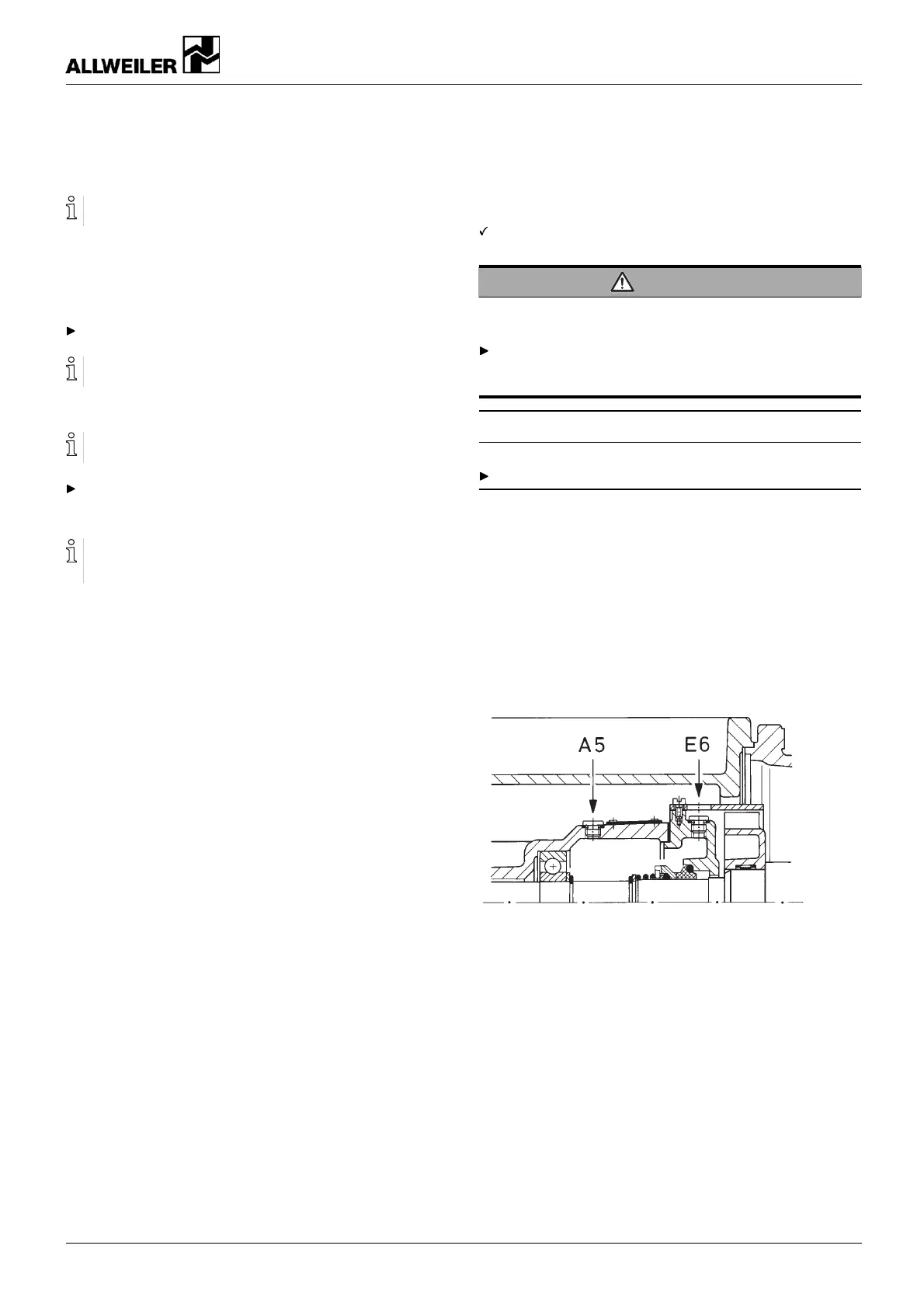

Filling and venting the bearing housing

(horizontal version)

1. Remove the screw plug A6/E6.

2. Fill slowly with pumped liquid up to the bottom edge of the

filling h ole.

– Ensure that the air can escape from the bearing hous-

ing.

3. Screw in and tighten the screw plug A6/E

6.

160-282/0 – 550 154 BA-2017.03 en-US NIT series 19

Loading...

Loading...