Layout and function

3 Layout and function

3.1 Labels

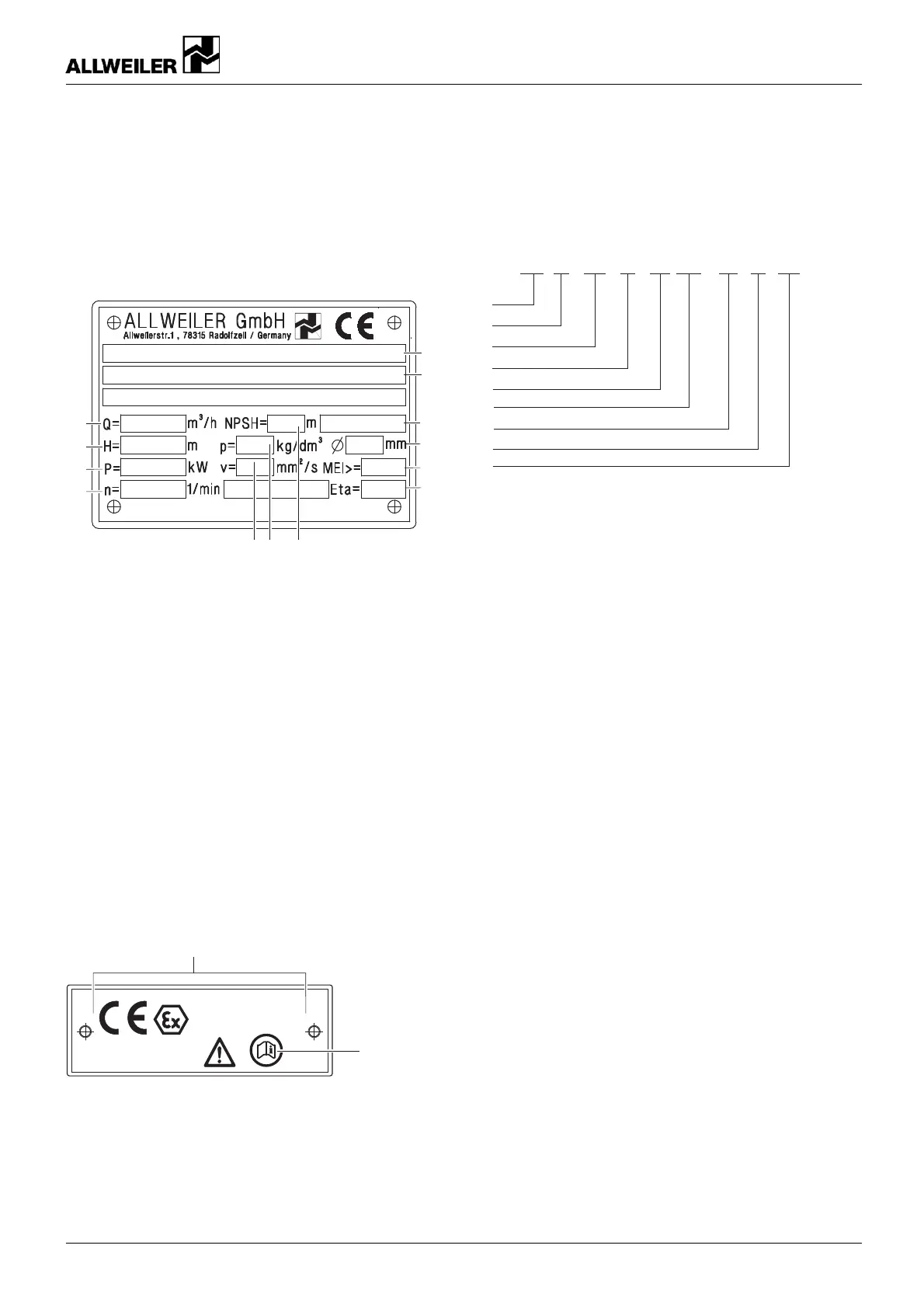

3.1.1 Type plate

11

10

13

12

4

5

6

1

2

3

98 7

Fig. 1 Type plate (example)

1 Pump number

2 Pumptypecode

3 Year of manufacture

4 Impeller diameter

5 Minimal efficiency index (MEI)

6Etaefficiency (—.- = not specified)

7 Pump NPSH value

8Density

9 Kinematic viscosity

10 Motor speed

11 Power consumption

12 Differential head

13 Flow rate

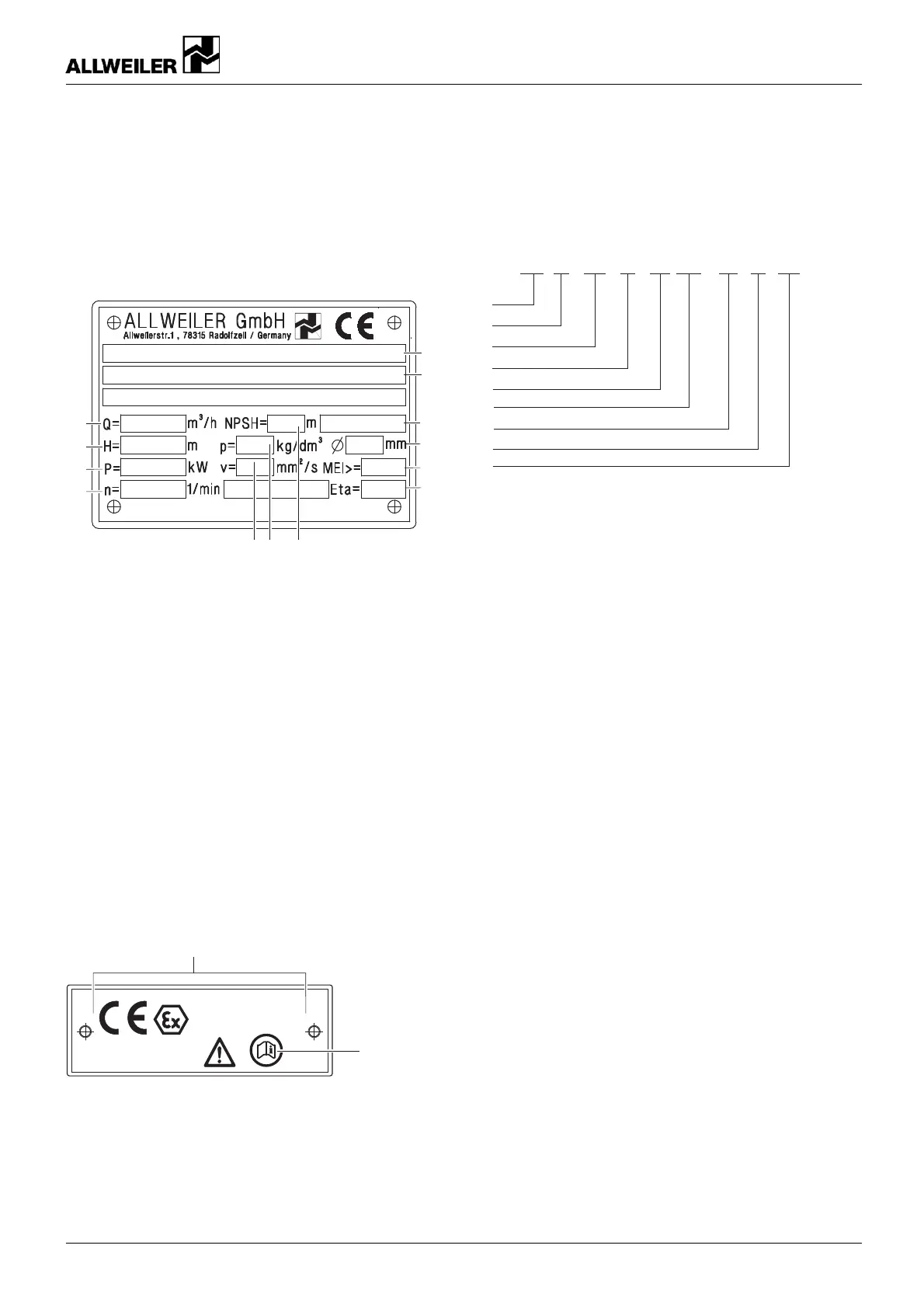

3.1.2 ATEX plate

Technical File No.:

EX9 03 09 45910 002

II 2 G c b Tx

1

2

Fig. 2 ATEX plate

(example)

1 Explosion protection mark

2 Refer

ence to ATEX additional instructions

3.1.3 Pump type code

1

2

3

4

NIT 40 – 200 / 01 / 180 U3D – W3 –38 / 300

5

6

7

8

9

Fig. 3 Pump type code (exa mple)

1Series

2 Size (standard nominal diameter)

3 Nominal impeller diameter

4 Hydraulic number

5 Actual impeller diameter [mm]

6 Shaft seal

7 Material key

8 Stub shaft bore hole diamete r [mm]

9 Outer diameter of motor bell housing o r intermediate

ring or flange size of electric motor

160-282/0 – 550 154 BA-2017.03 en-US NIT series 9

Loading...

Loading...