Setup and connection

5.4 Installing the motor

Only necessary if the pump aggregate is assembled on site

WARNING

Risk of injury due to overturning motor!

Secure the motor to preven t overturning before working on

the stub shaft.

NOTE

Damage due to incorrect installation!

Ensure that no excessive axial forces are applied to the

pump shaft.

Ensure that the stub shaft rests flush against the collar of

the motor shaft.

Stub shaft, free from oil and grease

The shaft key is not required for installation up to a stub

shaft bore hole diameter of 55 mm.

Stub shaft bore hole diameter (→ 3.1.3 Pump type code,

Page 9).

4

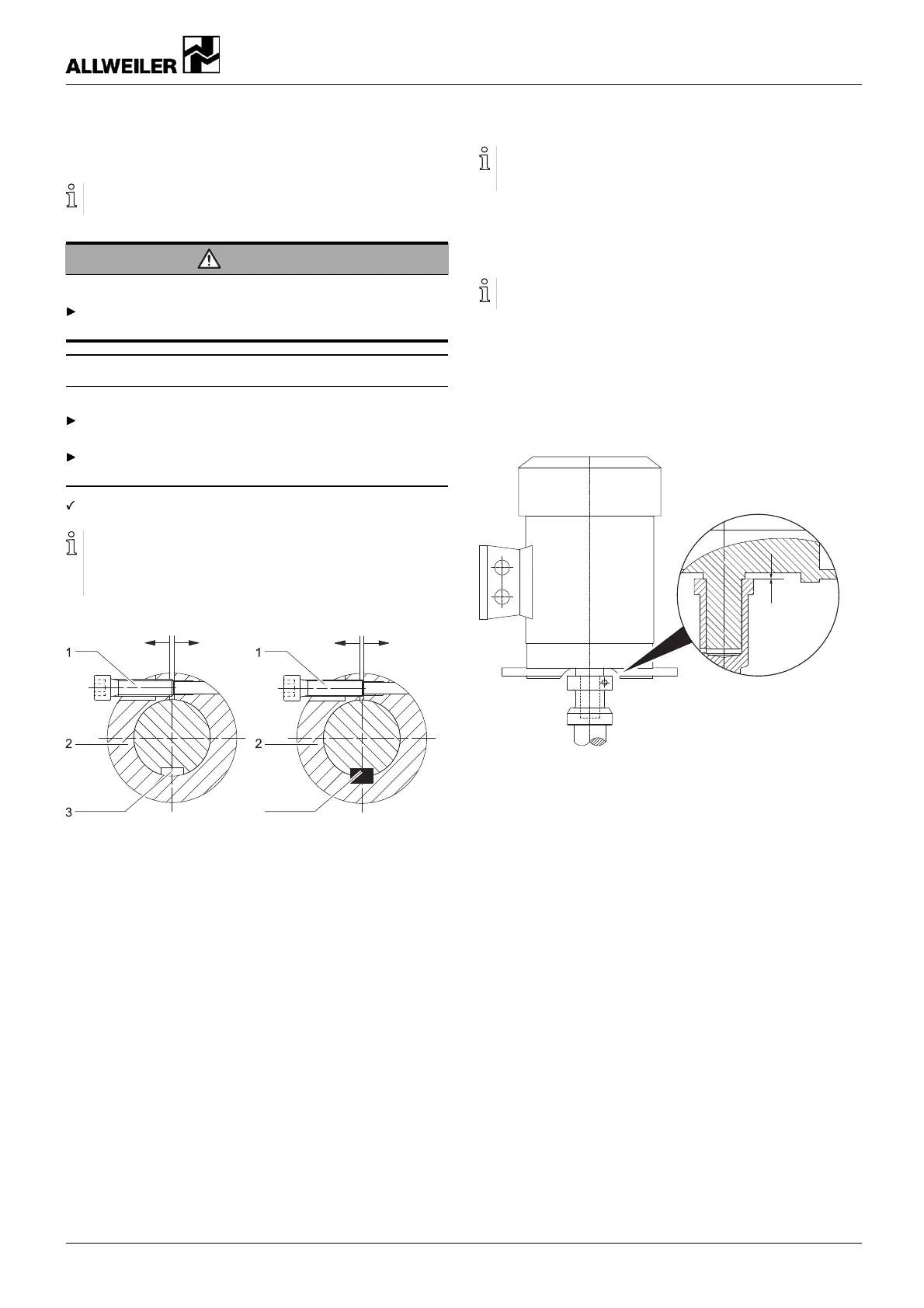

Fig. 8 Widening the stub shaft

1 Socket head cap screw

2 Stub s haft

3 Shaft key groove of motor shaft

4 Shaft key (from stub shaft bore hole diameter 60 mm)

1. Observe the foll owing during installation:

– Adhere to the specified tightening torques

(→ 9.2.5 Tightening torques, Page 37).

2. Remove the retaining clamp for the stub shaft from the

motor bell housing (341.01):

– Undo the b olts/nuts (901.10) for this purpose

(→ 9.1 Section al drawings, Page 31).

3. Undo the hexagon head bolts (901.07) and remove the

washers (554.07).

4. Remove one half of the guard sheet (686.01) from the

motor bell housing (341.01).

The Allen key required to undo the socket head cap screw

(914.14) is inserted in one of the two cast-in recesses in

the motor bell housing.

5. Undo the socket head cap screw (914.14) on the stub shaft

(220.xx) and unscrew it completely (→ 9.1 Sectional draw-

ings, Page 3 1).

Tighten the jack screw with a screwdriver without applying

any excessive force.

6. Widening the stub shaft (220.xx):

– Screw the M10 x 40 or M 12 x 40 jack screw (not

included in the scope of delivery) into the stub shaft.

7. From stub shaft bore hole diameter 60 mm: insert the shaft

key.

8. Turn the motor shaft so that the slot of the stub shaft is

opposite the shaft key groove of t he motor shaft.

0 mm

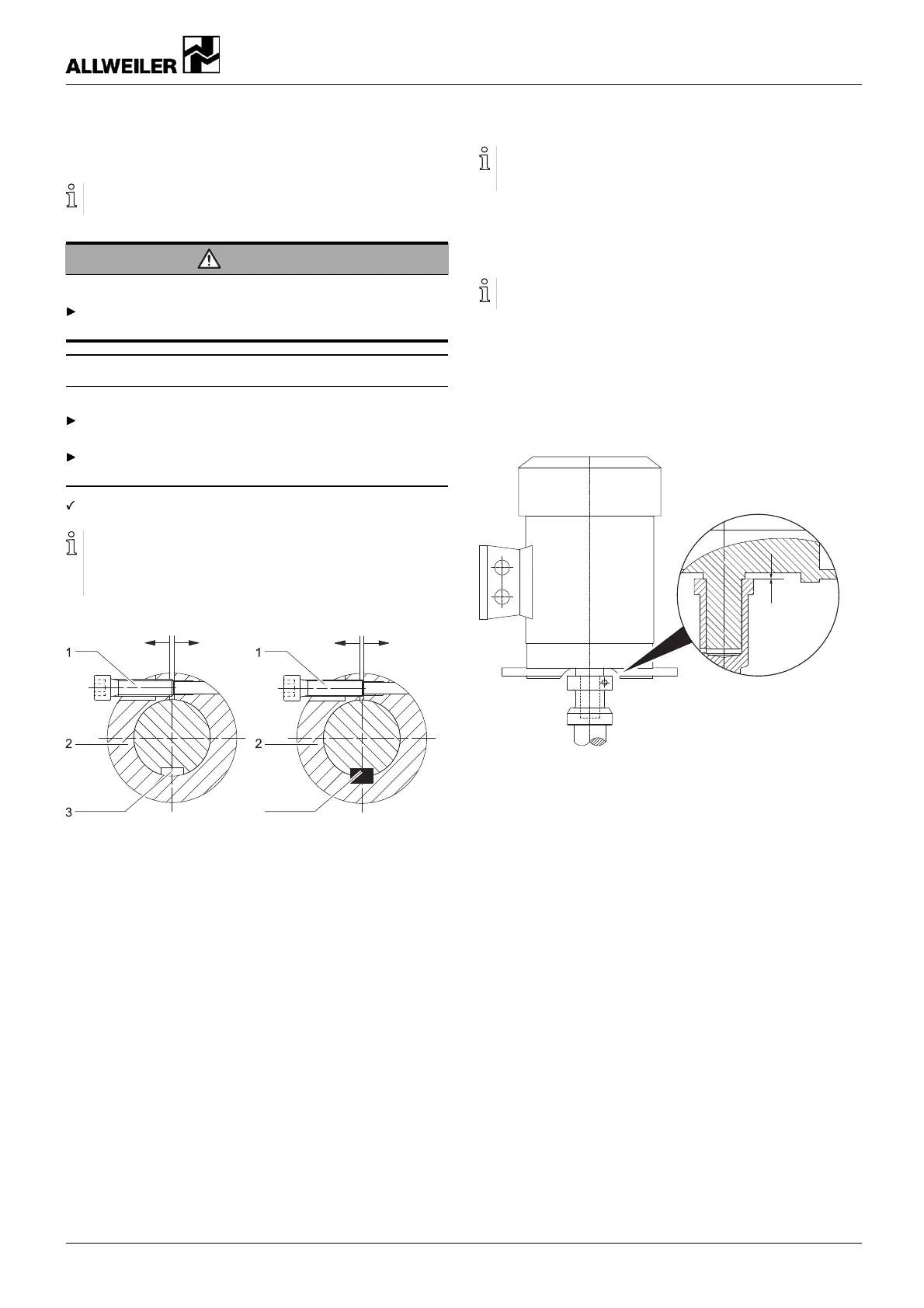

Fig. 9 Motor assembly

9. Carefully, slide on the motor u ntil the stub shaft rests flush

against the co llar o f the motor sha ft.

– Ensure that no excessive axial forces are a

pplied to the

pump shaft.

10. Screw in the motor bolts and tighte n them.

– Ensure that the stub shaft continues r esting flush

against the collar of t he motor shaft.

11. Undo and un screw the jack screw. Screw in the socket

head cap screw (914.14) and t ighten it with a torque wrench

(→ 9.2.5 Tightening torques, Page 37).

12. Install the safety equipment:

– Guard sheet for the motor bell hou

sing

13. Install the auxiliary devices:

– Manometer lines and h oldings on the pump

– Auxiliary piping

14. Turn the stub shaft by hand:

– Ensure the stub shaft can be turned easily without pres-

sure points.

160-282/0 – 550 154 BA-2017.03 en-US NIT series 17

Loading...

Loading...