Operation

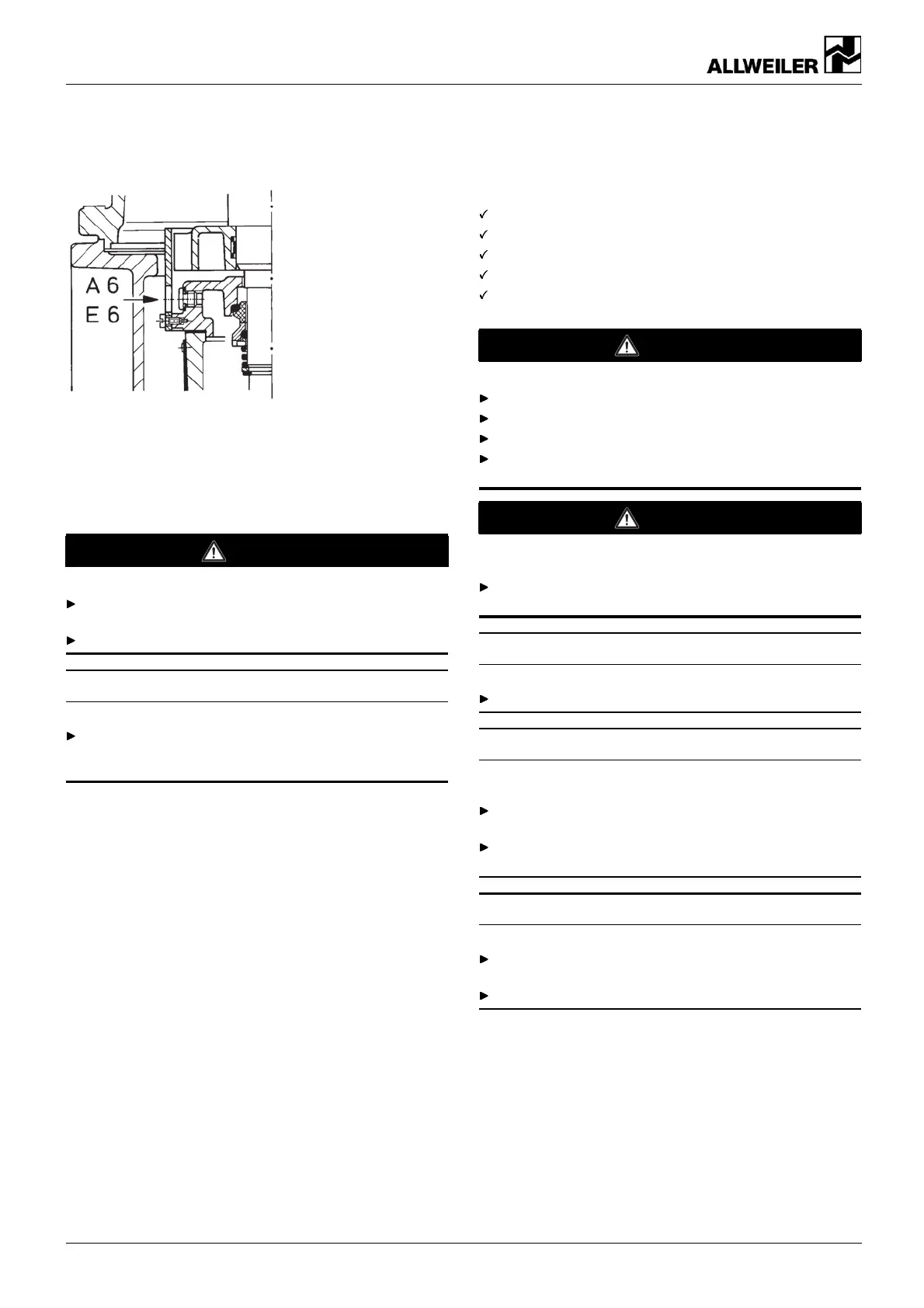

Filling and venting the bearing housing (vertical version)

1. Remove the screw plugs A5 and E6.

2. Fill slowly wi th pumped liquid in filling hole A 5 until liquid

escapes from vent opening E6.

3. Screw in and tighten screw plugs A5 and E6.

6.1.5 Checking the direction of rot atio n

DANGER

Risk of death due to rotating parts!

Use personal protective equipment when carrying out any

work on the pump.

Keep an adequate distan ce to rotating parts.

NOTE

Material damage due to incorrect direction of rotation!

Make sure the d irection of rotation of the motor corre-

sponds to the arrow indicating the dire c tion of rotation on

the motor bell housing.

1. Switch the motor on and immediately off again.

2. Check whether the directio n of rota tion of the mo tor corre-

sponds to the arrow indicating the dire c tion of rotation on

the pump.

3. If the direction of rotation is different: swap two phases

(→ 5.5 Electrical connection, Page 18).

6.2 Start-up

6.2.1 Switching on

Pump aggregate set up and connected properly

All connections stress-free and sealed

Any available auxiliary systems are ready for operation

All s afety equipment installed and tested for fu nctionality

Pump prepared, filled and bled properly

DANGER

Risk of injury due to running pump!

Do not touch the running pump.

Ensure that the coupling gua rd is attached.

Do not carry out any work on the running pump.

Allow the pump to cool down comp letel y before starting any

work.

DANGER

Risk of injury and poisoning caused by pumped medium

spraying out!

Use personal protective equipment when carrying out any

work on the pump.

NOTE

Material damage caused by dry running!

Make sure the pump is filled properly.

NOTE

Risk of cavitation when throttling down the suction flow

rate!

Fully open the s uction-side armature and do not use it to

adjust the flow rate.

Do not open the pressu re-side armature beyond the oper-

ating point.

NOTE

Material damage caused by overheating!

Do not operate the pump for long periods with the pressure-

side fitting closed.

Observe the minimum flow rate (→ o rder data sheet).

1. Open the suction-side armature.

2. Close t he pressure-side arma

ture.

3. Switch on the mo t or and ch eck it for smooth running.

4. Once the motor has reached its nominal speed, open the

pressure-side armatu re slowly until the operating point is

reached.

5. For pumps with hot pum

ped liquids, make sure any tem-

perature c hanges

do not exceed 5 K/min.

20 NIT series BA-2017.03 en-U S 160-282/ 0 – 550 154

Loading...

Loading...