1-42 American-Lincoln

MPV 60

LP COMPONENTS

LP FUEL TANKS

Standard D.O.T. LP fuel tank sizes have 14, 20, 33.5, and 43.5 pounds capacities. The liquid volume permitted

in these containers is less than the total volume of the cylinder. This provides for expansion of the LP fuel

should be temperature increase above the normal amounts. Excessive heat may cause the fuel to expand too

much causing the safety relief valve to vent some LP fuel, relieving internal tank pressure.

Each tank is marked showing the type of construction (liquid or vapor), the manufacturer, the date of manufac-

ture, the capacity, the weight, and the date of re-qualification. D.O.T. fuel tanks must be re-qualified (checked)

periodically. This re-qualification must be recorded and maintained for the life of the container.

LP fuel tanks are equipped with the following approved valves and fittings:

Safety Relief Valve - This is a spring loaded valve that relieves excessive pressures which may develop in the

tank due to unusual conditions.

Liquid Service Valve - Liquid is withdrawn from the tank through this valve. The LP tank may be filled through

this valve if the tank is not equipped with a filler valve.

Excessive Flow Valve - This valve is part of the Liquid Service Valve. It is mounted inside the tank and pre-

vents LP fuel from leaving the LP tank in the event of accidental breakage of external fittings or hoses. It permits

flow in either direction but stops outward flow if that flow becomes excessive.

Filler Valve - This valve is optional. If this valve is not present, the tank if filled through the service valve.

Liquid Level Gauge - This gauge is optional.

USE AND CARE OF LP TANKS

If an LP tank is damaged or leaking, it should be immediately removed to a designated safe area and the proper

personnel should be notified. Do not attempt to make repairs to the cylinder regardless of its conditions.

Repairs must be made by qualified personnel.

The care of an LP tank receives has a direct bearing on how long the tank can be used safely. LP tanks must

not be dropped, dragged, or slid across any surface. To move the LP tank, use a hand truck or roll the tank on

its foot ring while it is being held in a position slightly off the vertical.

CHANGING LP TANKS

Refueling machines with LP tanks is an important process. Refueling is accomplished by replacing the empty

LP tank with a full one.

The tank changing operation presents an opportunity for the machine operator to carefully inspect the tank, tank

fittings, the fuel lines and fuel line fittings. If abnormal wear is detected, the operator should report these findings

to the appropriate personnel for immediate action.

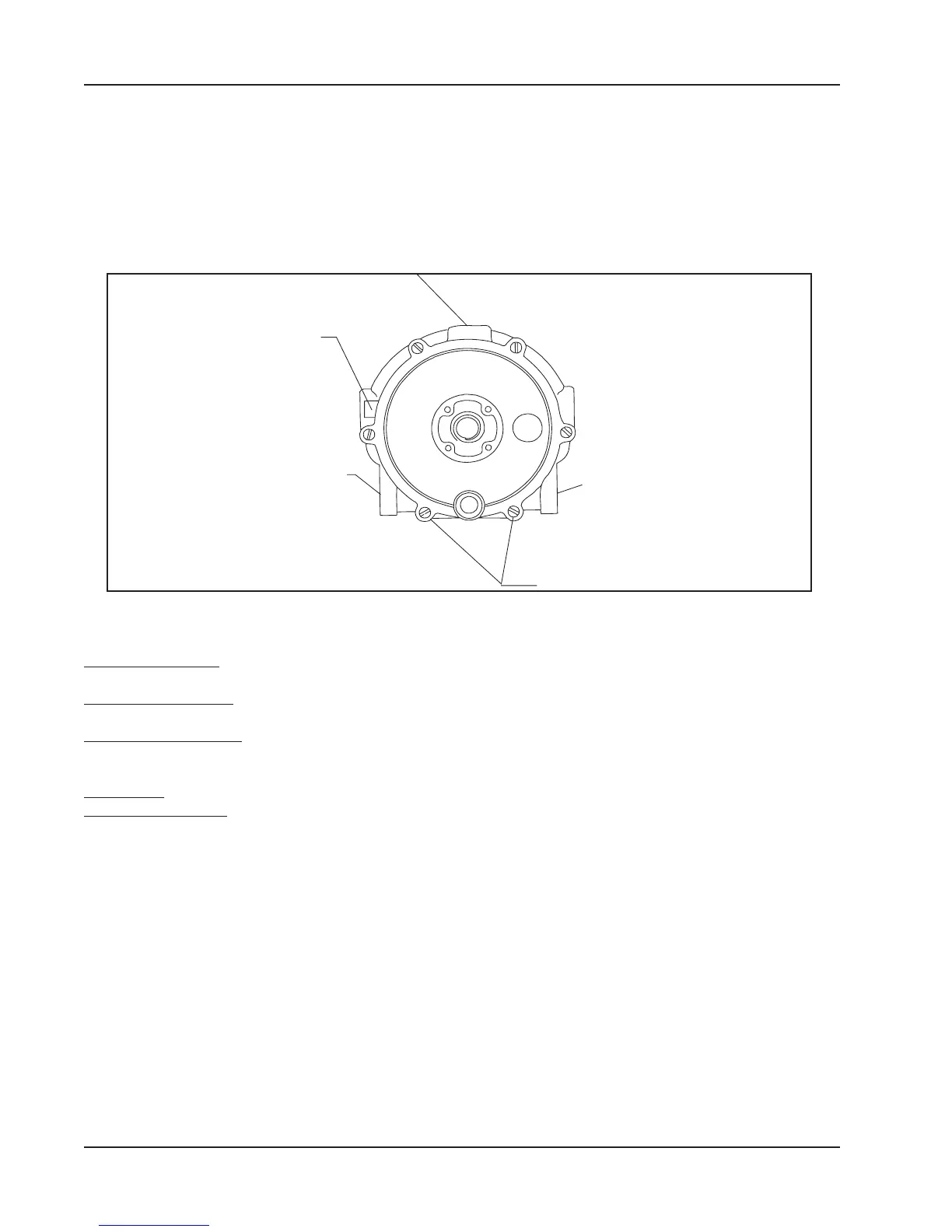

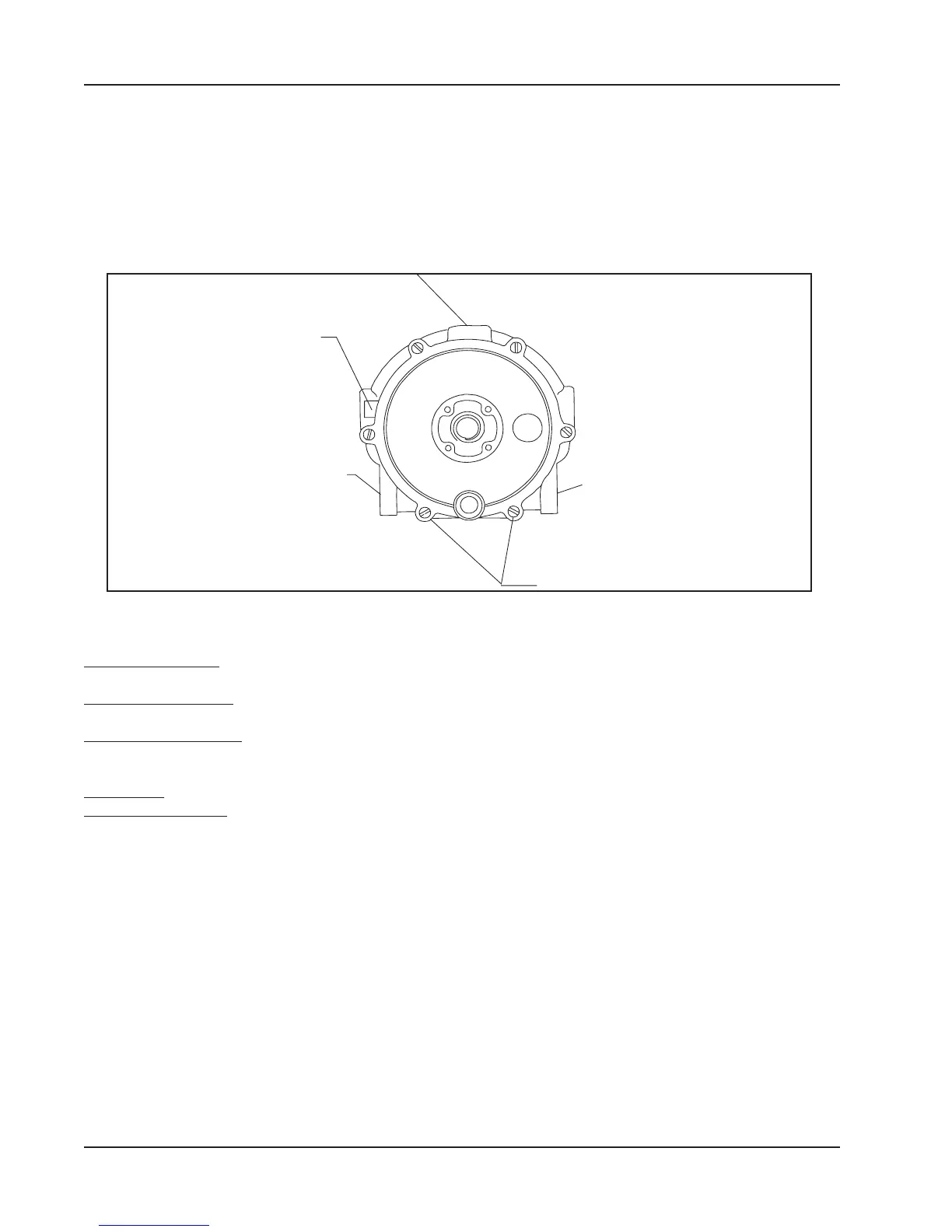

PLUG

VAPOR

OUTLET

P-4563A

WATER

P-4563A FIGURE 40

Loading...

Loading...