84

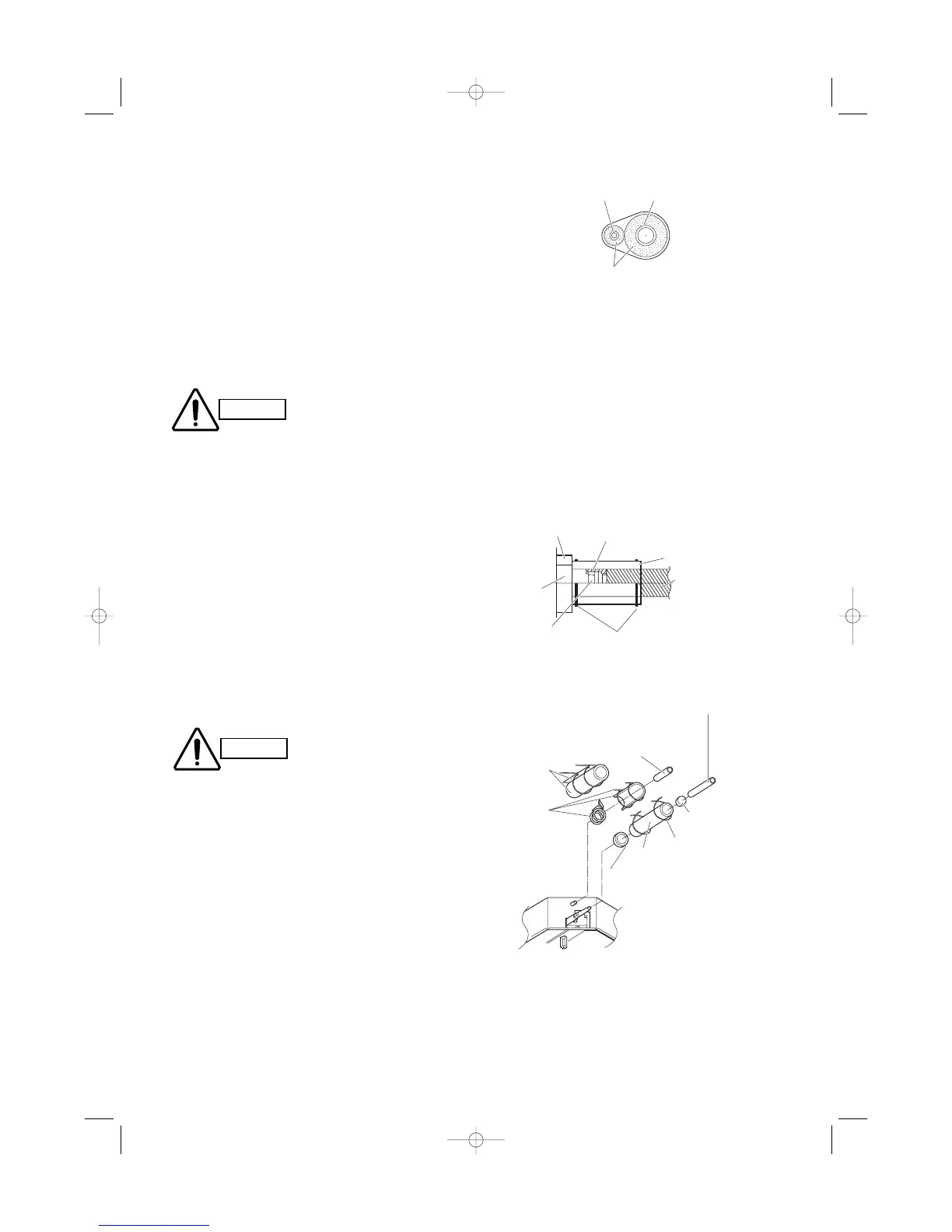

Fig. 7-8

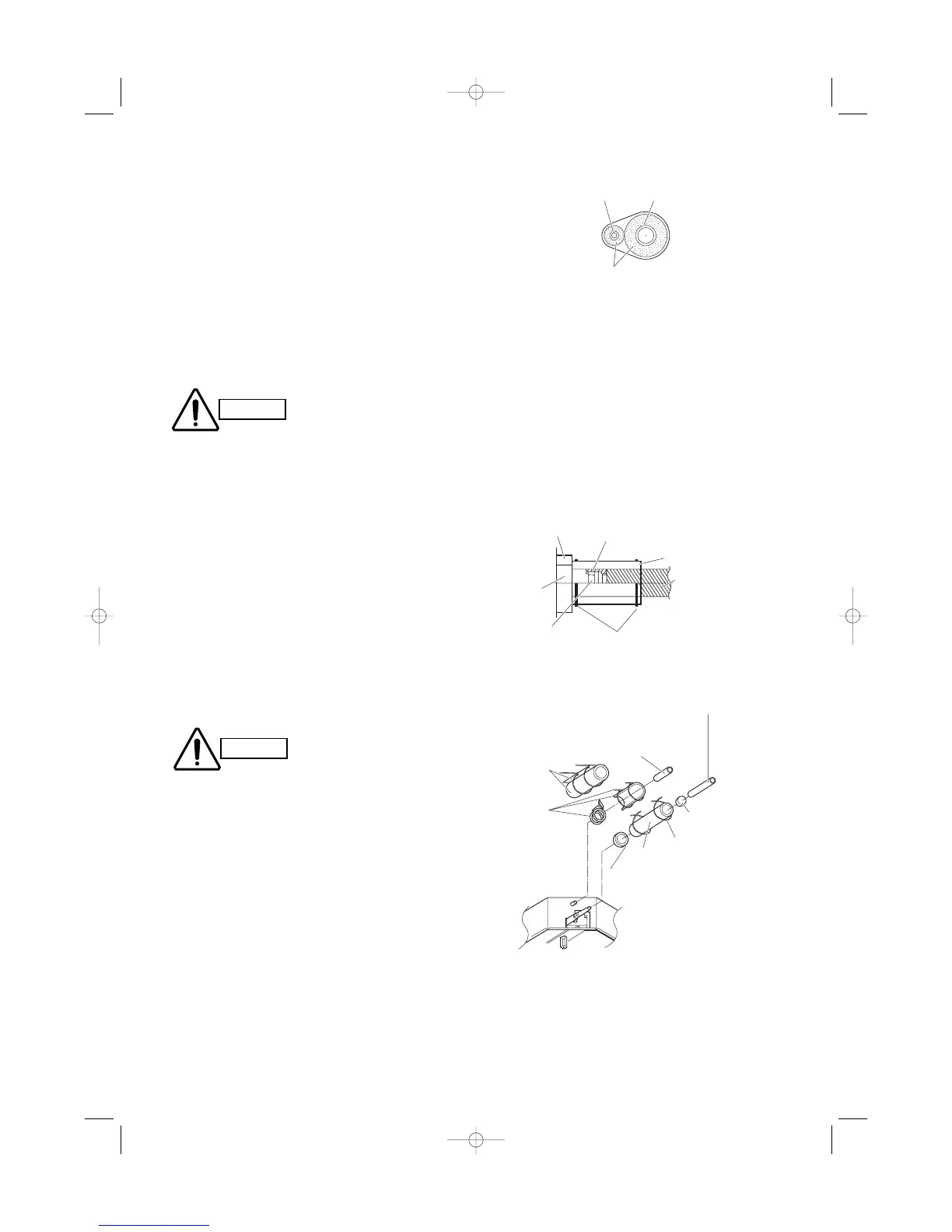

Fig. 7-9

7-3. Insulating the Refrigerant Tubing

Tubing Insulation

Thermal insulation must be applied to all unit tub-

ing, including distribution joint (purchased sepa-

rately).

* For gas tubing, the insulation material must be

heat resistant to 120°C or above. For other tubing,

it must be heat resistant to 80°C or above.

Insulation material thickness must be 10 mm or

greater.

If the conditions inside the ceiling exceed DB 30°C

and RH 70%, increase the thickness of the gas

tubing insulation material by 1 step.

Taping the flare nuts

Wind the white insulation tape around the flare nuts at

the gas tube connections. Then cover up the tubing

connections with the flare insulator, and fill the gap at

the union with the supplied black insulation tape.

Finally, fasten the insulator at both ends with the sup-

plied vinyl clamps. (Fig. 7-8)

Insulation material

The material used for insulation must have good insu-

lation characteristics, be easy to use, be age resis-

tant, and must not easily absorb moisture.

After a tube has been insu-

lated, never try to bend it

into a narrow curve

because it can cause the

tube to break or crack.

Two tubes arranged together

If the exterior of the outdoor

unit valves has been finished

with a square duct covering,

make sure you allow sufficient

space to use the valves and to

allow the panels to be

attached and removed.

Fig. 7-7

Loading...

Loading...