SECTION 3

OPERATING THE ASTROJET M1

28

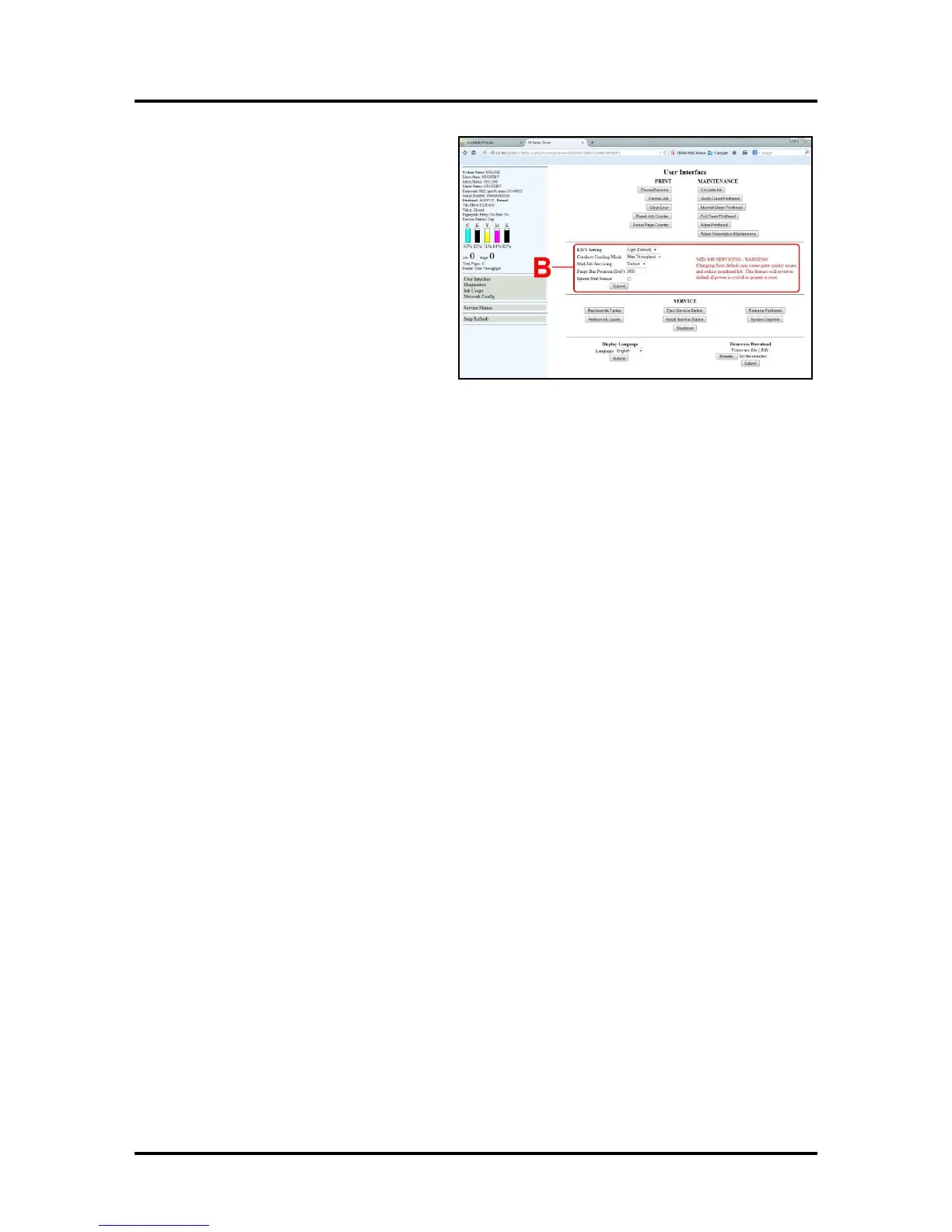

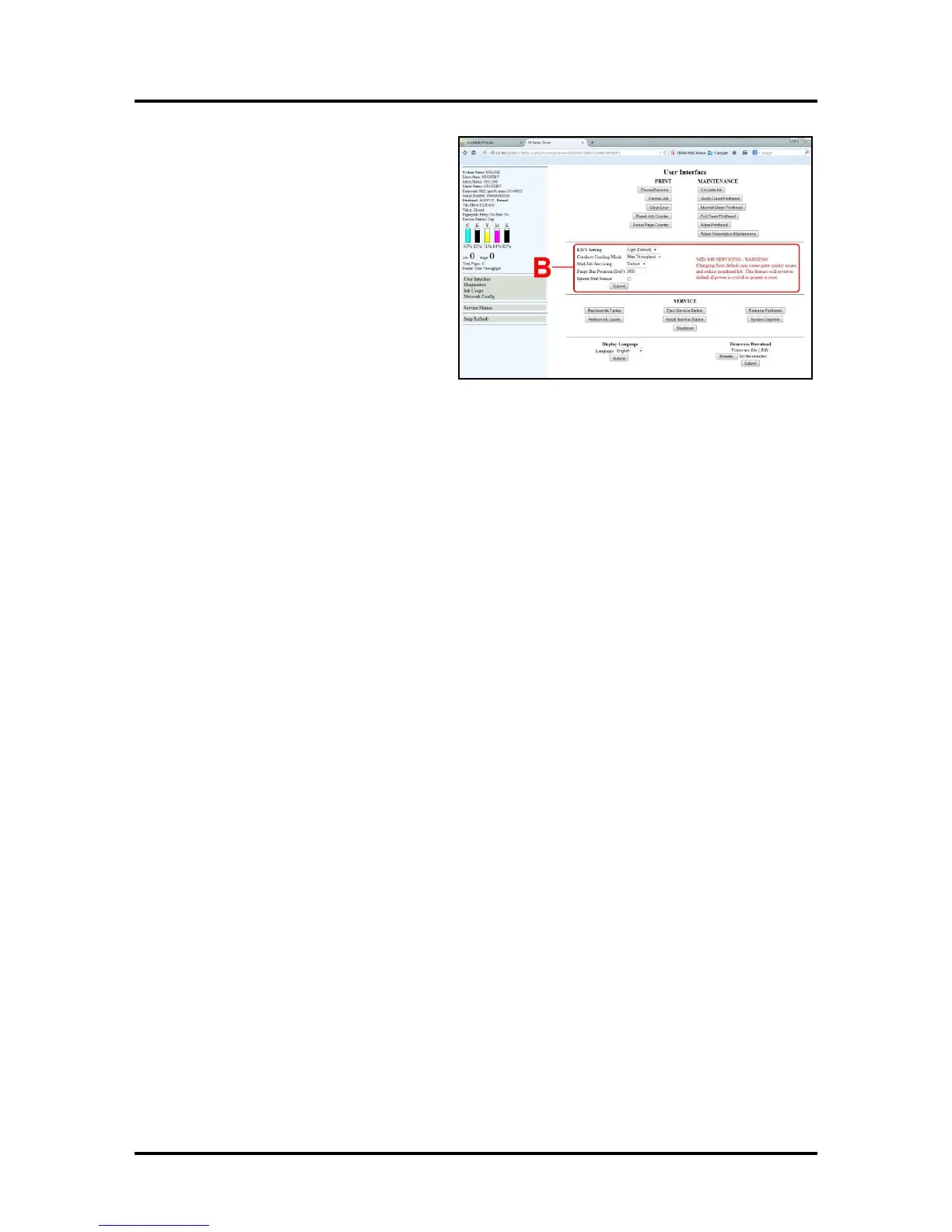

[B] SETUP Settings – Let you adjust automated

service and cleaning intervals, adjust the feeder

speed for a job, manually set the gap between

pieces and adjust the Printer for pre-printed

media.

KWS Setting – (Keep Wet Spitting) Keeps

Printhead hydrated while running a job. Select

from 3 settings: None, Light (default), Heavy,

to determine how much ink will “spit” from

the Printhead Nozzles. Set in conjunction with

“Mid-Job Servicing” which determines the

frequency of the Printer stopping for self-

servicing during a job.

Cutsheet Feeding Mode – Permits you to change how the Printer feeds media depending on the type of

job you are running:

Safe Feed – Leaves a larger gap between pieces to reduce overprinting onto the next piece. This

setting is useful for more intricate printing jobs or jobs requiring the best print quality.

Max_Throughput – Allows fastest printing speed. The Printer works like a stream feeder. This

setting is useful for simple printing jobs. NOTE: A few extra blank pieces may run through at the end

of the job.

NOTE: These two settings can be changed without stopping the job. Example: While running a job

in “Max-Throughput” you find that the media is jamming excessively due to speed. Open the

Toolbox, check “Safe Feed” and click “Submit”. The Printer will automatically adjust without

having to pause or stop the job.

Mid-Job Servicing – Sets the frequency of automatic maintenance cycles run during a job after a set

amount of media is run. Settings are: Default (14m), Level 4 (100m), Level 3 (250m), Level 2 (375m),

Level 1 (500m) and Off (. NOTE: Changing the setting from “Default” may cause print quality

issues and reduce Printhead life.

Purge Bar Position – In operation, the Printhead spits a small amount of ink in the gap between pieces to

keep the nozzles refreshed. For irregular-shaped pieces (like an envelope flap), the sensor may “read” the

lower end as the edge and spray on the tip of the flap instead of the actual gap between pieces. This

feature allows you to manually set the gap (1 micron increments) to account for the extra length needed to

reach the actual gap.

Ignore Exit Sensor – Checking this box turns the Exit Sensor OFF. The Sensor may not detect the

trailing edge of a piece of pre-printed media if the back of that media is dark or black. (Example: adding

addresses to a pre-printed postcard.) This may cause the Sensor to react as if a jam has occurred. Turning

the Sensor OFF prevents these “false jams” from stopping the job.

Click “Submit” to apply settings.

Loading...

Loading...