- 66 -

6.4.9 Servicing air inlet shut-down

valve

The air shut-off valve is part of the refinery

equipment and is mounted on the piping between the

engine inlet and the motor charge air cooler outlet.

The valve prevents combustion air to enter the engine.

When an overspeed is detected, the engine will

shutdown (emergency stop) and the air shut-off valve

will close.

To reset the air shut-off valve, pull the handle of the

valve up until a click is heard.

6.4.10 Servicing water separator

The water separator in the back of the unit filters

water condensate out of the compressed air, before

the air is discharged through the outlet valves.

Water condensate from the water separator is drained

through a nipple in the bottom of the frame. Connect

a drain hose to the nipple and make sure that the

condensate is properly disposed of.

Service the filter of the water separator every 500

hours.

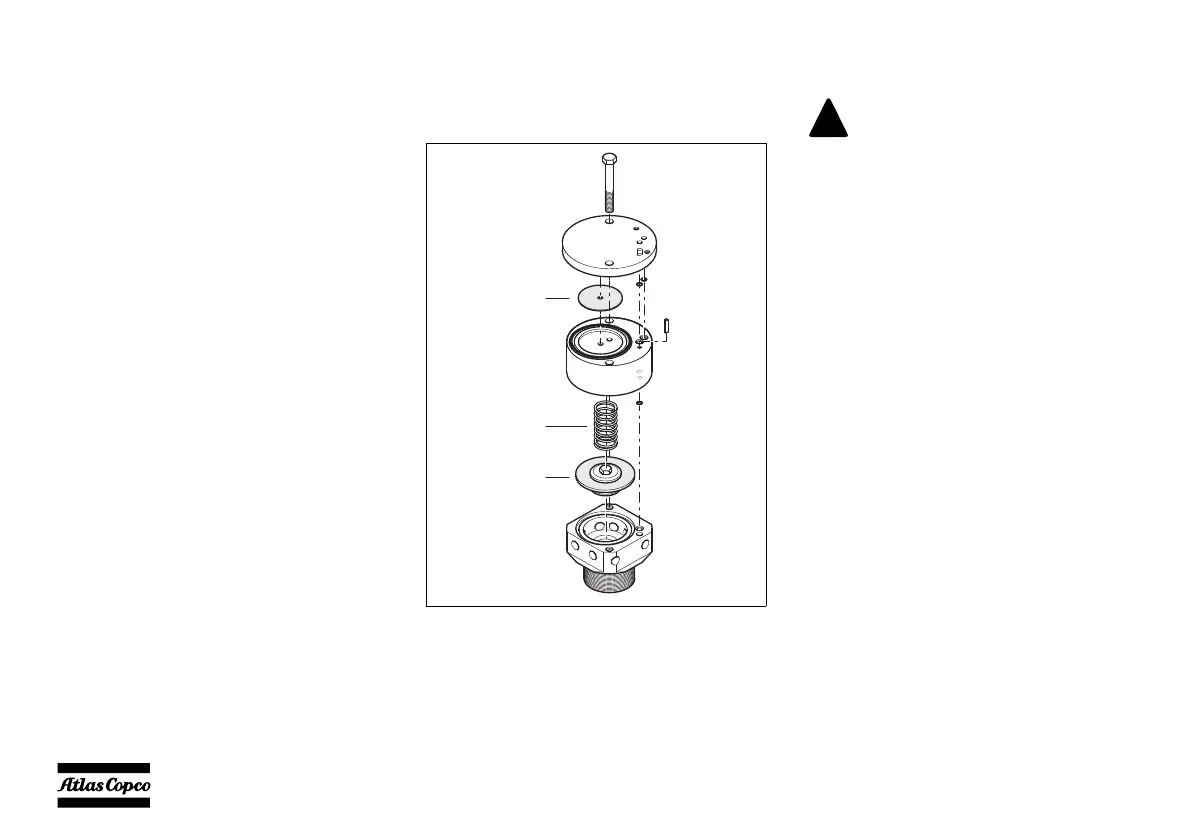

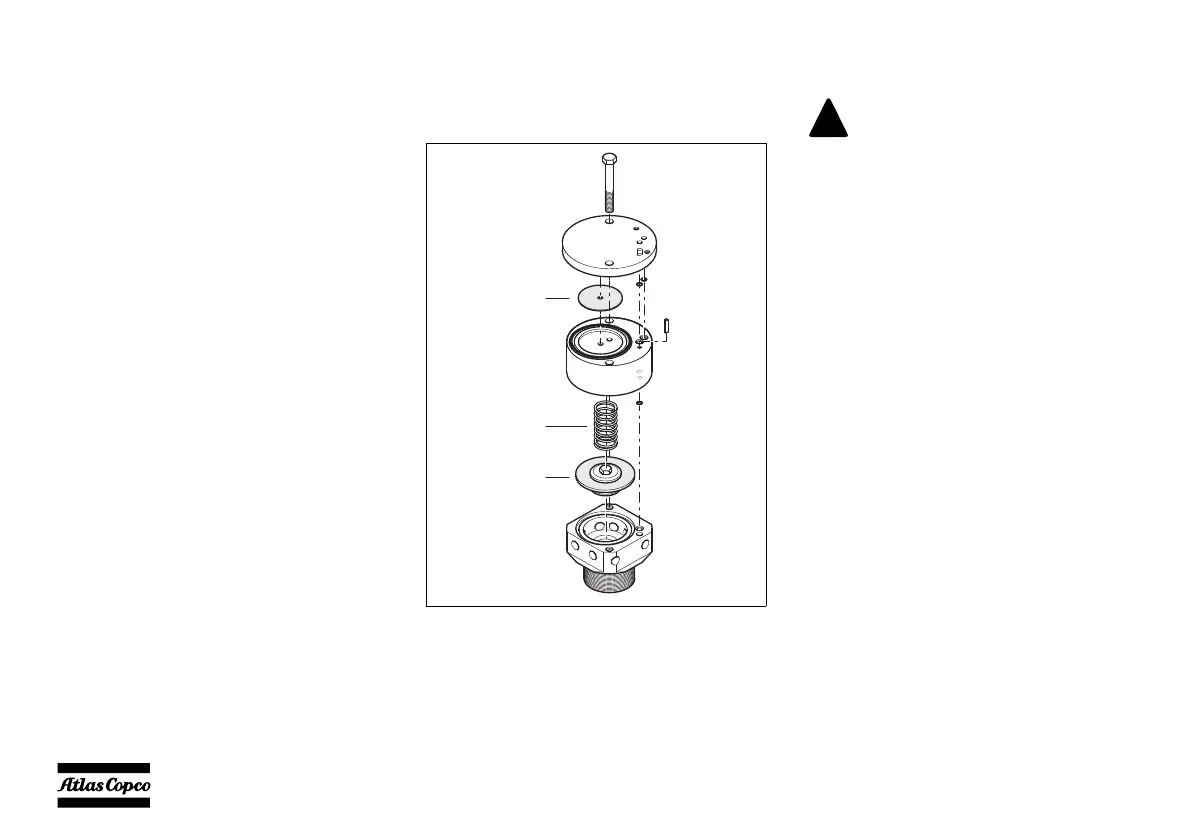

6.4.11 Servicing electric blow-off valve

The blow-off valve, fitted on the MP air inlet pipe, is

opened to release air when the air inlet throttle valve

is closed; it closes when the throttle valve is opened.

Replace the membrane, the diaphragm valve

assembly (1) and the spring every 2000 hours (kit

2906 0568 00).

6.4.12 Servicing automatic fire

suppression system

Preventive maintenance

Check the heat sensitive detection wire for actual

damage. A damaged detection wire can lead to a false

release of the fire suppression system.

Periodic maintenance

To give maximum assurance that the system will

operate as intended, maintenance must be performed

every six months or sooner, depending on the

operating and/or environment conditions.

Maintenance must be performed by authorized

personnel only. Please contact Atlas Copco.

All maintenance activities are to be recorded in a

logbook.

Do not use a high pressure cleaner

to clean the fire suppressing system

or parts of it.

Loading...

Loading...