11. Setting of the limit switching

11.1 Setting for end position CLOSED (black section)

.

Turn handwheel clockwise until valve is closed.

.

After having reached the end position, turn back handwheel approximately

1/2 a turn (overrun). During test run (page 17) check overrun and, if

necessary, correct setting of the limit switching.

.

Press down and turn setting spindle A (figure K-1) with screw driver

(5 mm) in direction of arrow, thereby observe pointer B.

While a ratchet is felt and heard, the pointer B moves 90° every time.

When pointer B is 90° from mark C, continue turning slowly. When pointer

B has reached the mark C, stop turning and release setting spindle. If you

override the tripping point inadvertently (ratchet is heard after the pointer

has snapped), continue turning the setting spindle in the same direction

and repeat setting process.

11.2 Setting for end position OPEN (white section)

.

Turn handwheel counterclockwise until valve is open, then turn back

approximately 1/2 a turn.

.

Press down and turn setting spindle D (figure K-1) with screw driver

(5 mm) in direction of arrow, thereby observe pointer E.

While a ratchet is felt and heard, the pointer E moves 90° every time.

When pointer E is 90° from mark F, continue turning slowly. When pointer

E has reached the mark F, stop turning and release setting spindle. If you

override the tripping point inadvertently (ratchet is heard after the pointer

has snapped), continue turning the setting spindle in the same direction

and repeat setting process.

11.3 Checking the switches The red test buttons T and P (figure K-1) serve for operating the limit

switches manually.

.

Turning T in direction of the arrow LSC (WSR) triggers limit switch CLOSED.

.

Turning P in direction of the arrow LSO (WÖL) triggers limit switch OPEN.

14

Multi-turn actuators SA 07.1 – SA 16.1

with actuator controls AMB 01.1/AMB 02.1 Operation instructions

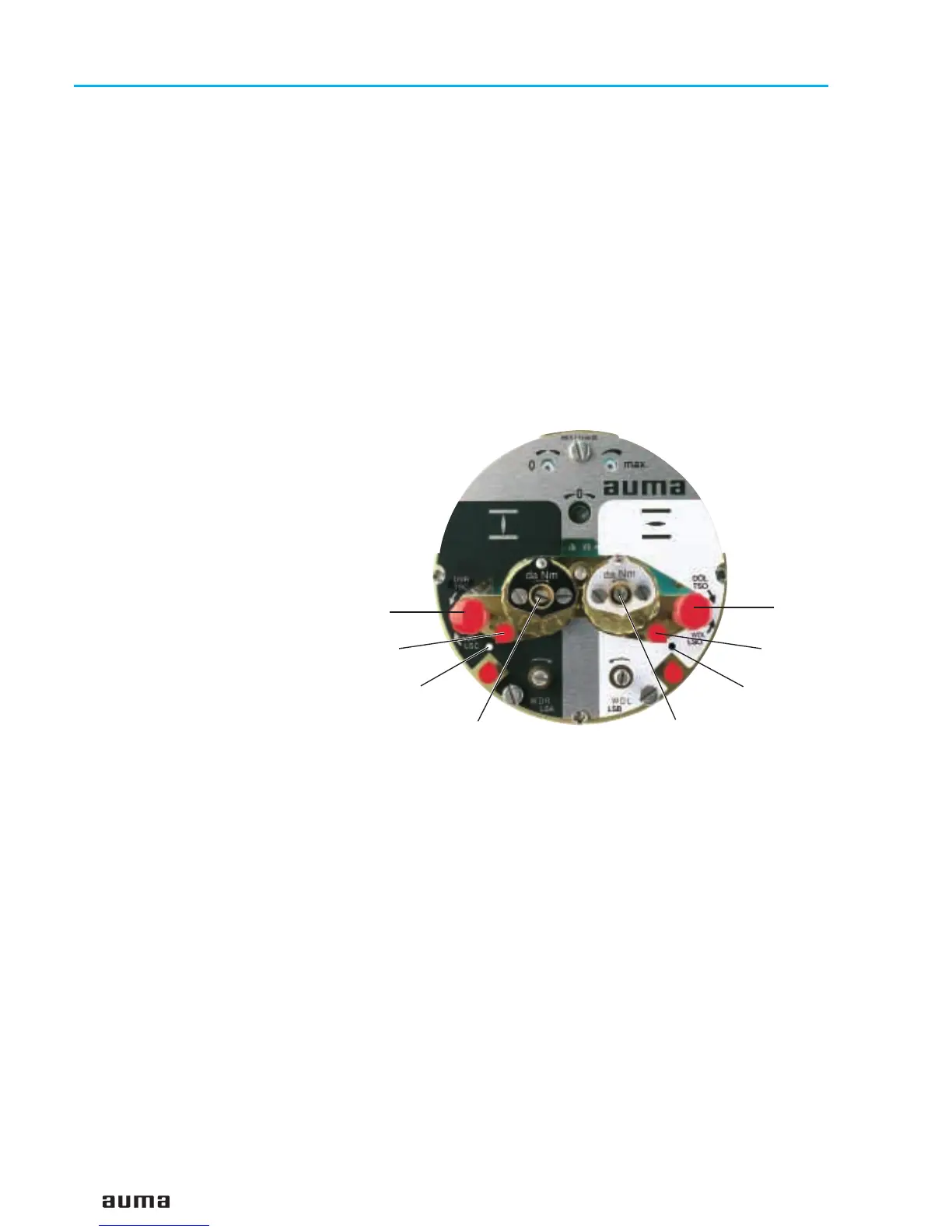

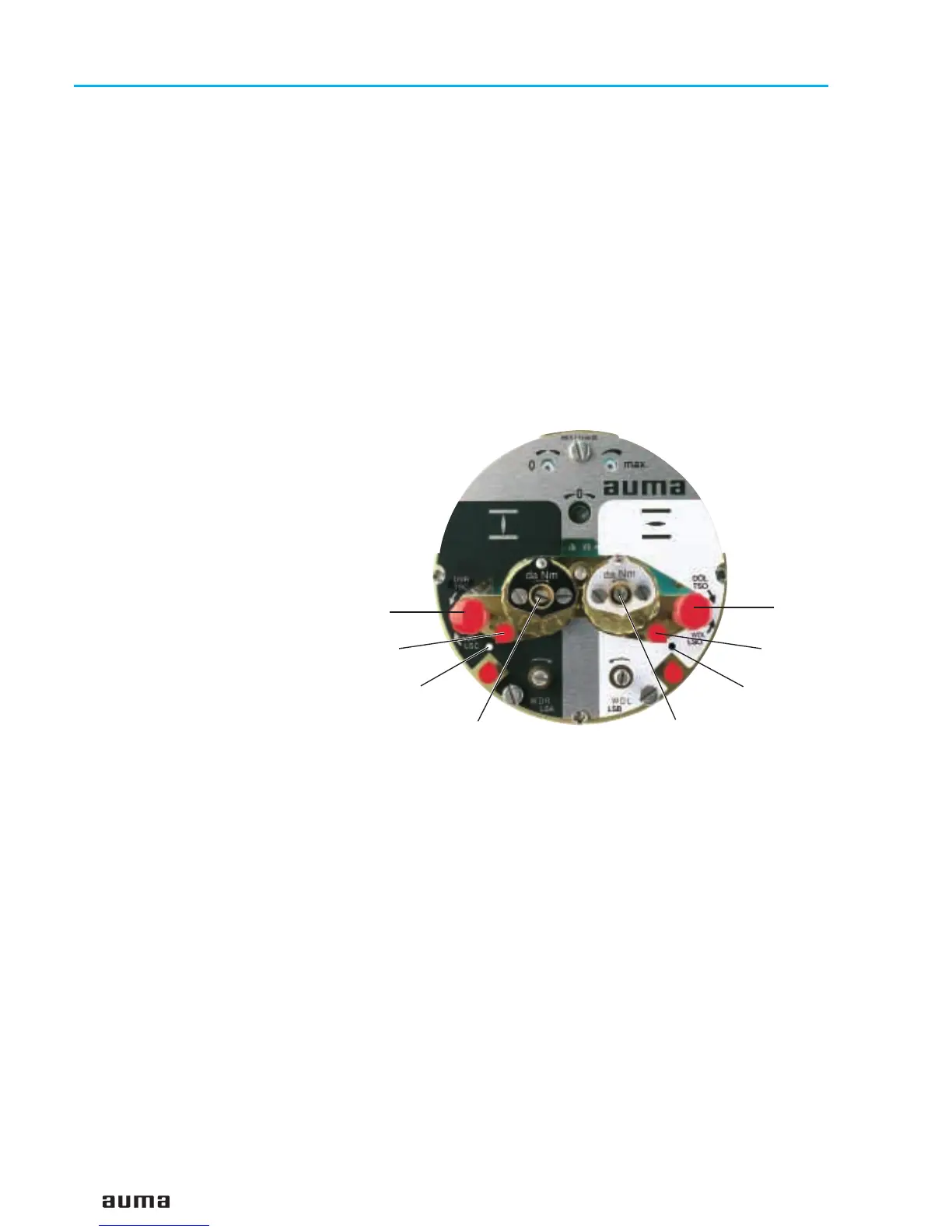

Figure K-1: Control unit

A

T

B

C

D

P

E

F

Loading...

Loading...