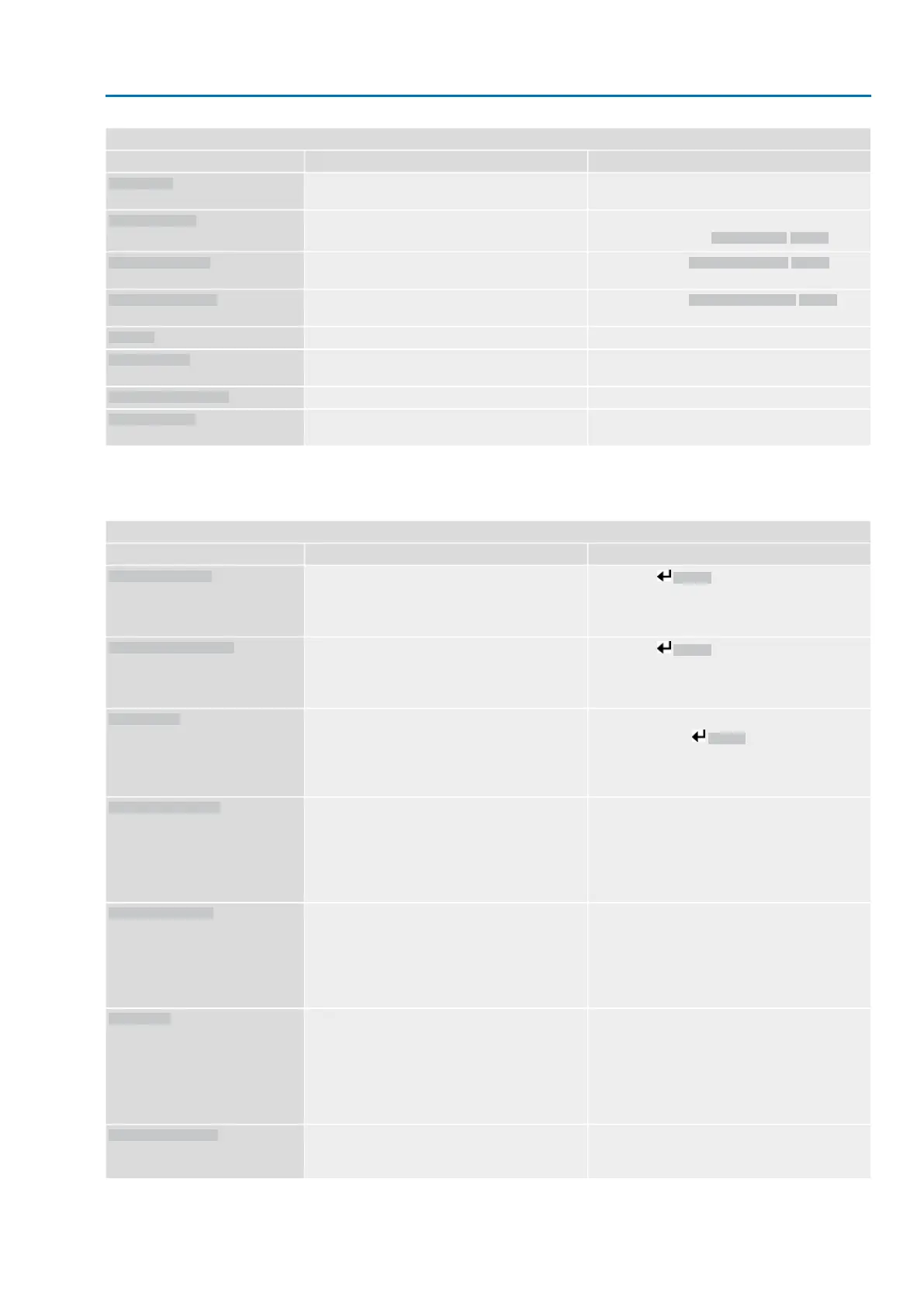

Warnings and Out of specification

RemedyDescription/causeIndication on display

Perform RESET or restart PVST.Partial Valve Stroke Test (PVST) was aborted or

could not be started.

PVST abort

●

Check movement at actuator.

●

Check parameter Reaction time M0634.

No actuator reaction to operation commands within

the set reaction time.

Wrn no reaction

Check parameter Wrn torque OPEN M0768, re-set

if required.

Limit value for torque warning in direction OPEN

exceeded.

Torque wrn OPEN

Check parameter Wrn torque CLOSE M0769, re-

set if required.

Limit value for torque warning in direction CLOSE

exceeded.

Torque wrn CLOSE

Refer to separate Manual Functional Safety.SIL sub-assembly fault has occurred.

SIL fault

1)

Execution of PVST (Partial Valve Stroke Tests) is

required.

PVST required

Maintenance is required.

Maintenance required

Checking and fault remedy are required. Refer to

FQM operation instructions.

FQM fault

FQM fail safe flt

2)

For actuators controls in SIL version1)

For actuators with fail safe unit2)

Table 32:

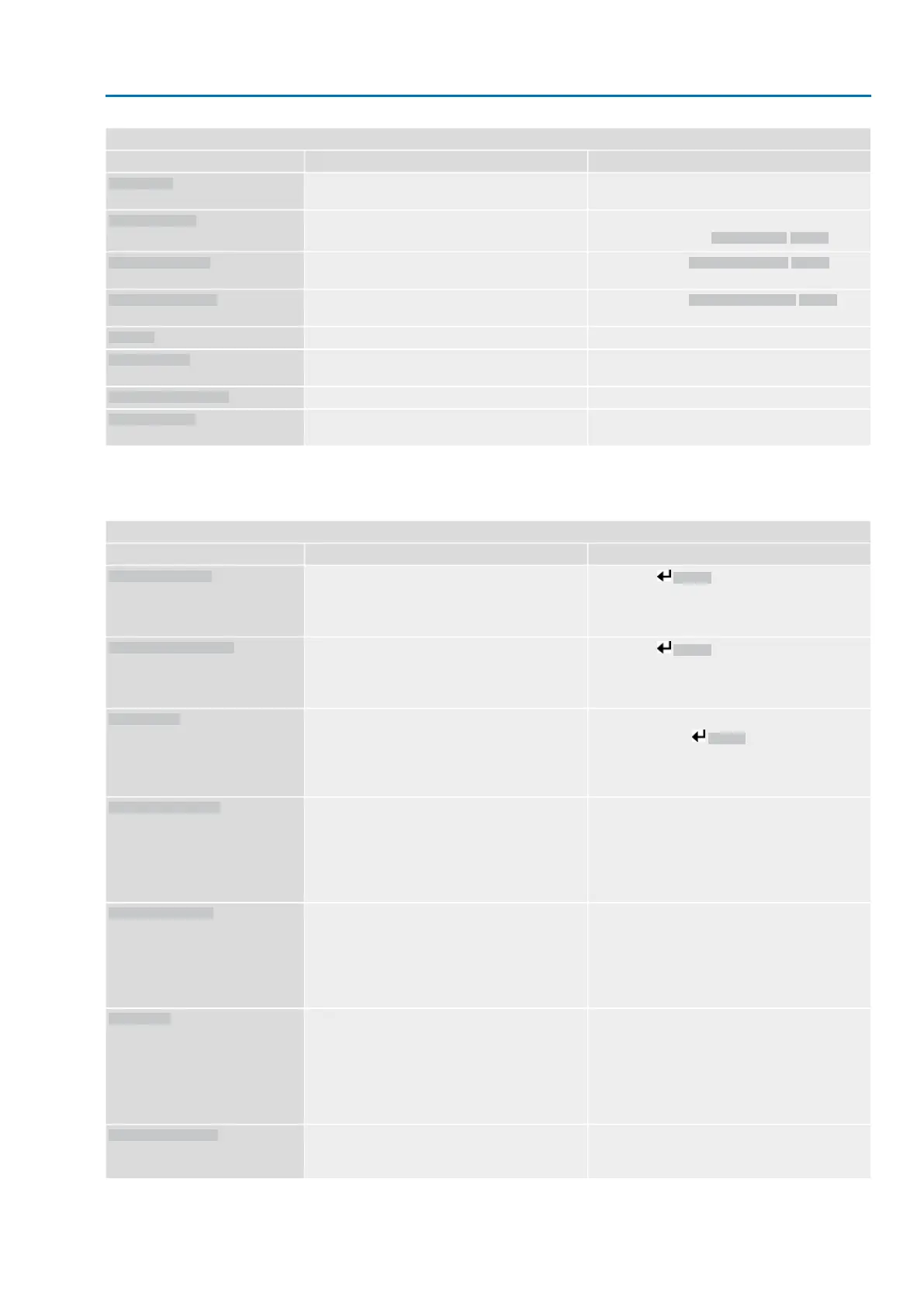

Faults and Failure

RemedyDescription/causeIndication on display

Drucktaster Details drücken, um Einzelmeldun-

gen zu sehen.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 11:

Configuration error has occurred.

Configuration error

Drucktaster Details drücken, um Einzelmeldun-

gen zu sehen.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 22:

Configuration error has occurred.

Config. error REMOTE

AUMA service

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 14:

Internal error has occurred.

Internal error

Perform one of the following measures:

●

Issue operation command in direction OPEN.

●

Set selector switch to position Local control

(LOCAL) and reset fault indication via push

button RESET.

●

Execute reset command via fieldbus.

Torque fault in direction CLOSE

Torque fault CLOSE

Perform one of the following measures:

●

Issue operation command in direction CLOSE.

●

Set selector switch to position Local control

(LOCAL) and reset fault indication via push

button RESET.

●

Execute reset command via fieldbus.

Torque fault in direction OPEN

Torque fault OPEN

Test/connect phases.

●

When connecting to a 3-ph AC system and with

internal 24 V DC supply of the electronics:

Phase 2 is missing.

●

When connecting to a 3-ph or 1-ph AC system

and with external 24 V DC supply of the elec-

tronics: One of the phases L1, L2 or L3 is

missing.

Phase fault

Correct the sequence of the phase conductors L1,

L2 and L3 by exchanging two phases.

The phase conductors L1, L2 and L3 are connected

in the wrong sequence.

Only applicable if connected to a 3-ph AC system.

Incorrect phase seq

75

SAEx 07.2 – SAEx 16.2 / SAREx 07.2 – SAREx 16.2 Control unit: electronic (MWG)

ACExC 01.2 Non-Intrusive Profinet Corrective action

Loading...

Loading...