Page B–10 Stellar

®

SR55 Series Soft Starter User Manual – 1st Ed, Rev F – 09/18/2019

Appendix B: Soft Starter Application Considerations

b.3.2 – The induCTion moTor (ConTinued)

Obviously, the larger the difference between the developed torque and the absorbed torque,

the faster the acceleration and the quicker full speed is reached, and the greater the stresses

experienced by the supply and drive systems during the acceleration process. An “ideal”

start would accelerate the load with just sufficient force to reach full speed smoothly in a

reasonable time, and with minimum stress to the supply and drive mechanisms.

Generally speaking, the motor speed/torque characteristic is controlled by the rotor

resistance. A motor with high rotor resistance can generate its peak torque (pull-out torque)

at standstill, giving the high break-away torque characteristic which reduces steadily as the

speed increases, and becomes zero at synchronous speed. At the other end of the scale, a

motor with a very low rotor resistance will produce a low starting torque, but will generate

its peak torque closer to the synchronous speed. Consequently, this type of motor runs at

full power with higher operating efficiency and low slip speed. It is possible to combine the

twin requirements of high starting torque and efficient full-speed operation within a single

motor by techniques such as double-cage or deep bar design, and this usually is the motor

characteristic chosen for lifting and hoisting applications:

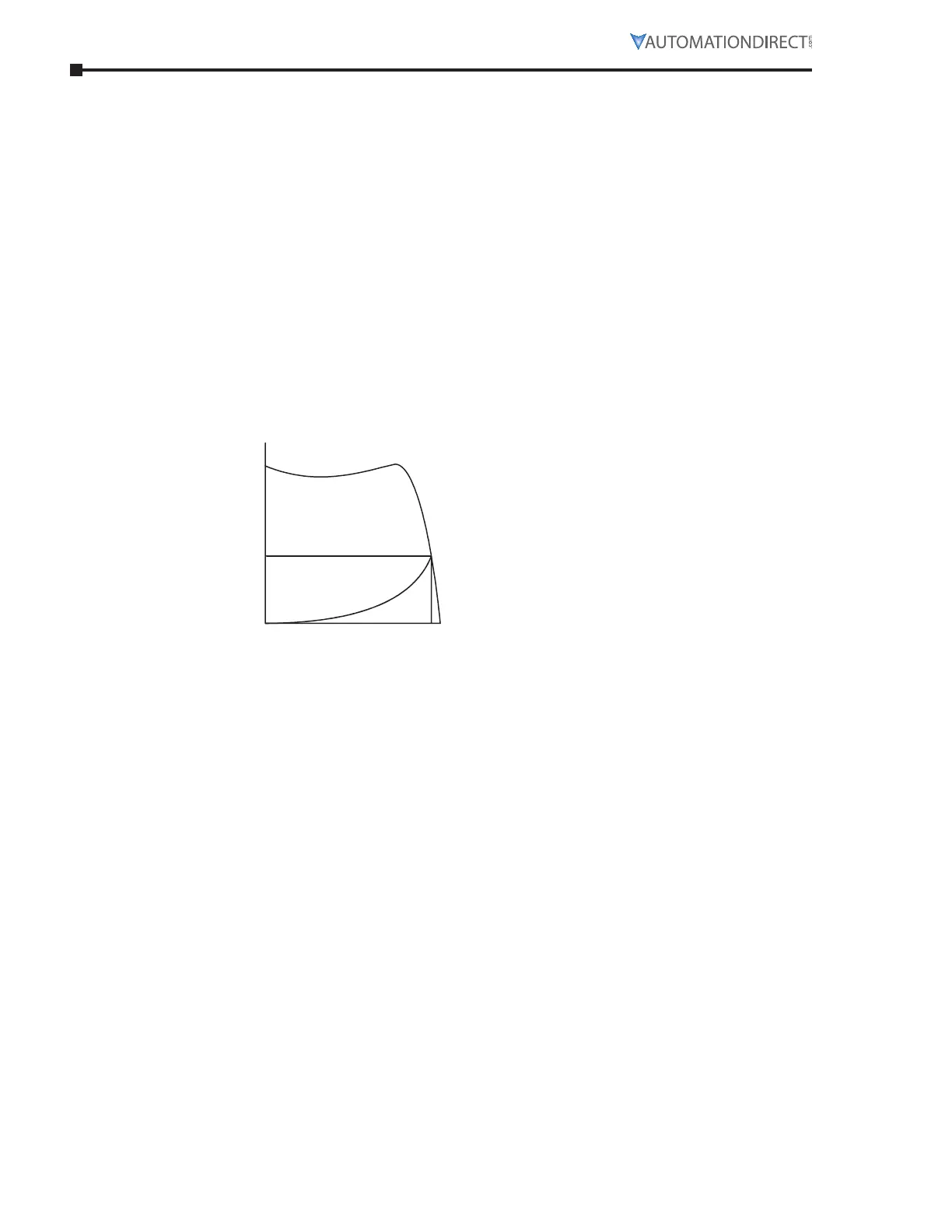

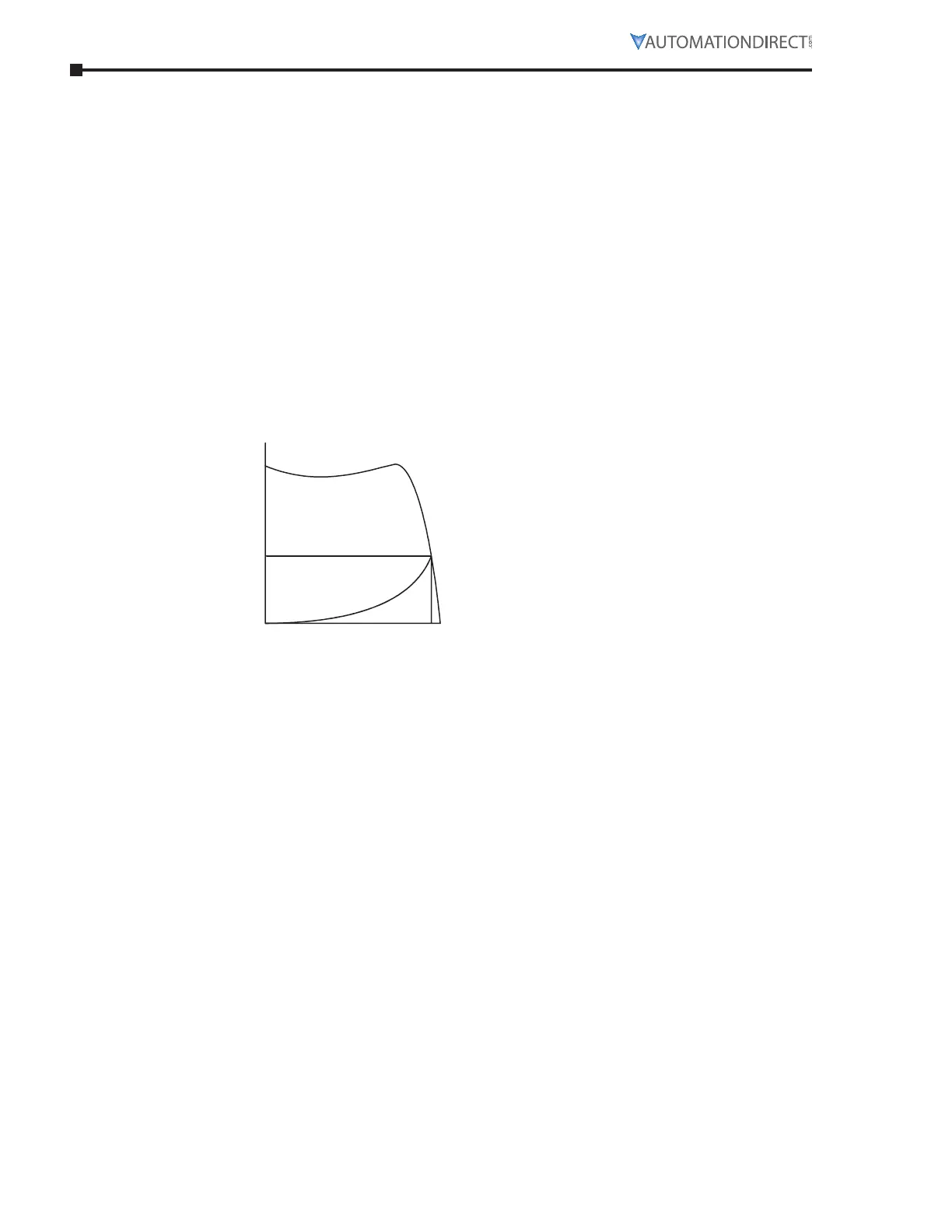

figure b.3.2.4: Torque/speed Curve – high sTarTing Torque

Torque

( LRT, M

A

)

Pull Out Torque ( M

K

)

TORQUE

Pull-up Torque

Full Load Torque ( FLT, M

N

)

Synchronous speed

Torque/Speed Curve – High Starting Torque

0 SPEED S

However, most induction motors are designed to have a “standard” characteristic that

provides a compromise between starting torque and operating efficiency. To summarize,

an induction motor will only start and accelerate when it produces more torque than the

connected load absorbs. This is true for all speeds, including standstill and full speed.

b.3.3 – sTarTing induCTion moTors

Starting a demagnetized induction motor from standstill is a demanding and complex process.

At the instant of switching, all the energy must be present that is necessary to magnetize the

motor, to provide the acceleration force, to supply the kinetic energy of the rotor and load,

and to overcome the mechanical and electrical losses. To do so at full supply voltage places

considerable stresses on the supply, the motor windings, and the iron cores of the stator and

rotor. Excessive acceleration of a rotor when the mechanical load is small can produce torque

oscillations in the shaft, causing severe wear to transmissions, gears and drives. Excessive

acceleration when the load inertia is high, such as in centrifugal fans, causes belts to slip on

the pulleys, producing rapid wear and early failure.

Loading...

Loading...