42

microspeed® uni motor system

Aesculap Power Systems

5.3.3 Manual cleaning/disinfecting

¾ Use an appropriate neutral, alkaline or mildly alkaline cleaning/

disinfecting agent according to the manufacturer’s instructions. Do

not immerse the product in any fluid.

¾ Remove encrusted materials with a soft nylon brush. Do not use harsh

cleaning agents or metal brushes.

¾ Clean difficult-to-access areas with soft round plastic brushes of

fitting diameter.

¾ Carry out intensive final rinse with distilled, demineralized or fully

desalinated water.

¾ Inspect surfaces and difficult-to-access areas for visible debris. If

necessary, repeat the cleaning/disinfection process.

¾ Use a lint-free cloth or a compressed-air gun for drying the product.

¾ Make certain that difficult-to-access areas and blind holes are dried,

too.

5.3.4 Control, care and inspection

¾ Allow the product to cool down to room temperature.

¾ Inspect the product after each cleaning and disinfecting cycle to be

sure it is clean, functional and undamaged.

¾ Check that the suction control lever can be moved.

¾ Spray-lubricate the friction surfaces of the unlocking sleeve and the

suction control lever, using Aesculap STERILIT® oil spray.

5.3.5 Packaging

¾ Always follow the instructions for use of the respective packaging and

storage equipment (e.g. instructions for use TA009721 for Aesculap

ECCOS® storage system).

¾ Insert the product in its proper position in ECCOS® storage GB580R, or

put it on a tray in such a way that the product is protected against

damage. Observe the weight limit for each tray/container.

¾ Pack trays in a way that is appropriate for the sterilization process (e.g.

in Aesculap sterile containers).

¾ Pack the product in such a way that the packaging will prevent

recontamination of the product in the period between reprocessing

and reuse.

5.3.6 Sterilization method and parameters

¾ Sterilize with steam, taking note of the following:

Carry out steam sterilization via an approved steam sterilization

procedure (e.g. sterilizer in conformance with EN 285/ANSI/AAMI/

ISO 11134-1993, ANSI/AAMI ST46-1993 and validated in

conformance with EN ISO 17665 or EN 554/ISO 13683). In the

fractioned vacuum process, sterilization must be carried out using the

134 °C/2 bar program with a minimum holding time of 5 minutes.

Note

Steam sterilization at 134 °C for a holding time of 18 min can adversely

affect the service life of the product.

¾ Make certain that the motor cables are not kinked or coiled up too

tightly. The coil radius has to be larger than 10 cm.

¾ When sterilizing several products at the same time in one steam

sterilizer: Make sure that the maximum allowable load capacity of the

steam sterilizer, as specified by the manufacturer, is not exceeded.

5.3.7 Sterilization for the US market

• Sterilization of the device may be accomplished by steam.

• Aesculap does not recommend the device be sterilized by “Flash” or

chemical sterilization.

• Surgical instruments may also be placed within an Aesculap rigid ster-

ilization container (sterile container) for processing under generally

accepted hospital in-use conditions.

The recommended sterilization parameters are as follows:

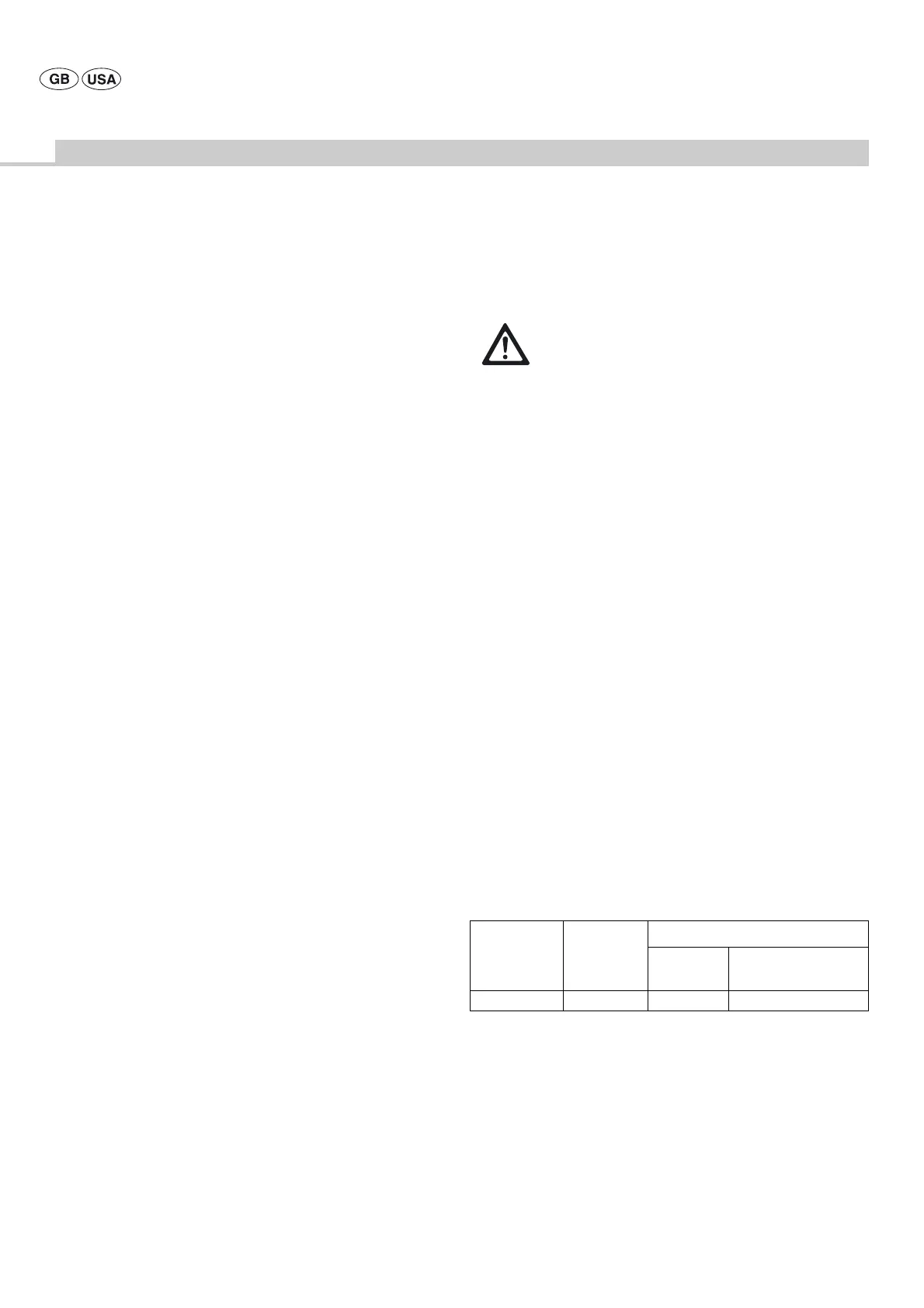

WARNING for the US market

If this device is/was used in a patient with, or suspected of having

Creutzfeldt-Jakob Disease (CJD), the device cannot be reused and

must be destroyed due to the inability to reprocess or sterilize to

eliminate the risk of crosscontamination.

5.3.8 Storage

¾ Store reprocessed products under conditions as germ-free as possible,

in a dry, dark, cool and dust-protected room.

CAUTION

Damage to motor cables GD672 and GD673 caused by

sterilization in sterilizers of small volume! Hot wall

surfaces (>150 °C) in the sterilizer can damage the

motor cable!

¾ Protect the motor cable (e.g. by wrapping it in a

cloth).

Sterilization

method

Temp.

Minimum exposure time

Wrapped

In a sterile container

system

Pre-vacuum 270—275 °F 4 min 4 min

Loading...

Loading...