Troubleshooting Page 32/44

MID_M2000_BA_02_1004

6. Troubleshooting

Error messages can be displayed via the 4 digital outputs. By means of the error list type

and frequency of the errors can be logged and analyzed, also see chapter Programming:

Info/Help.

The following error messages can be displayed:

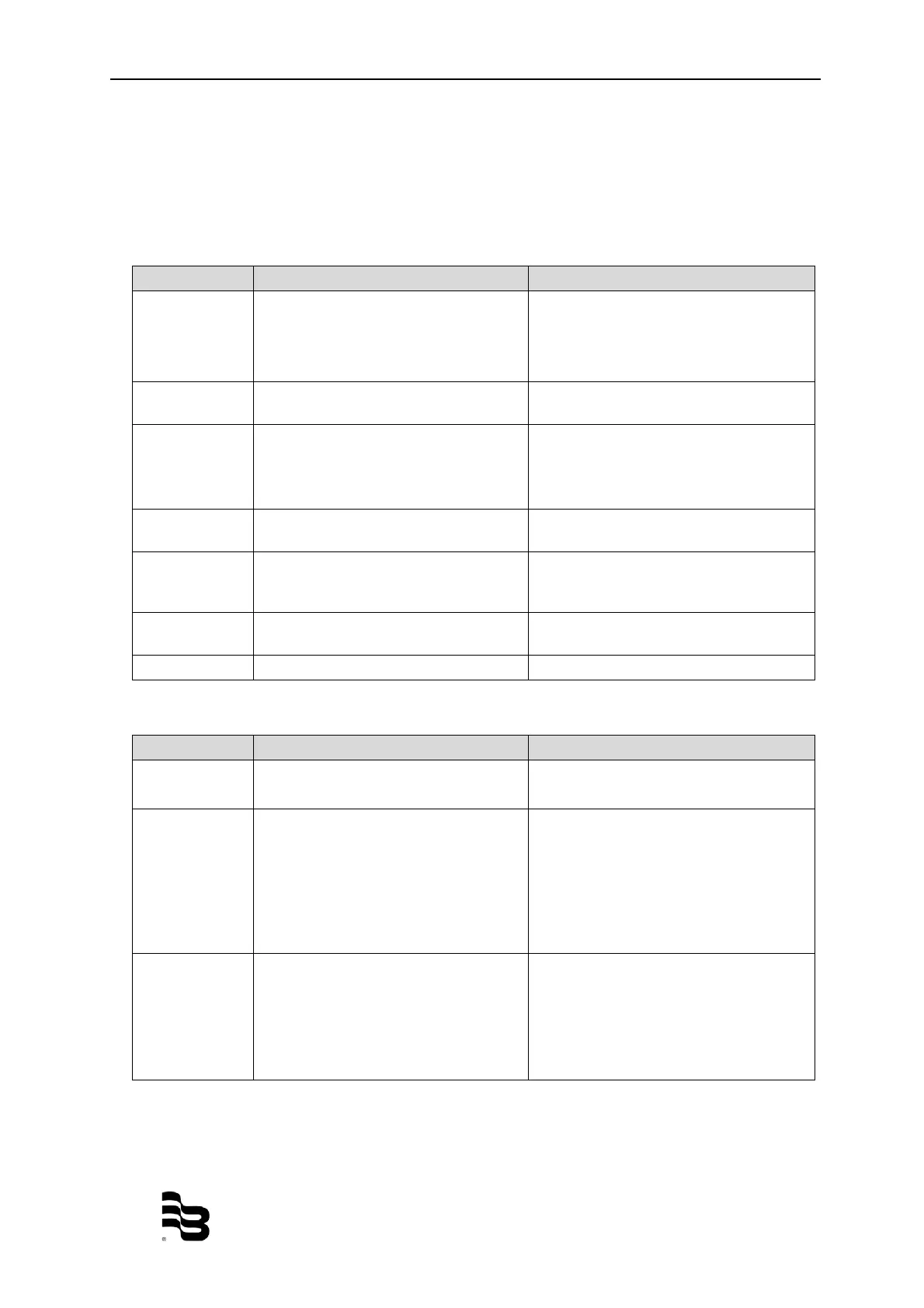

Description Possible Cause Recommended Action

Err: Coil Meter not connected.

Connection to meter interrupted.

Detector electronics or coils

defective.

Check if meter is connected and make

sure that cable connection is not

interrupted.

Otherwise contact Service Department.

Wrn: Pulse

Sync

False synchronization of pulse output

Err: empty pipe Pipe may not be full.

Make sure that pipe is always filled at

the measuring point.

Eventually calibrate anew, see

calibration of fluid monitoring

Err: full scale

Actual flow rate is exceeding the

programmed.

Reduce flow rate or increase the

programmed full scale.

Err: ADC range Input signal from detector too high.

Check the grounding scheme of the

meter installation. See grounding

section in manual.

Err: Tot.

rollover

Number of totalizer digits is exceeded

See programming / Info/Help / Totalizer

Rollover

Err: ATOD INT No measuring signal on analog input. Contact service.

Some frequently occurring errors are listed in the following:

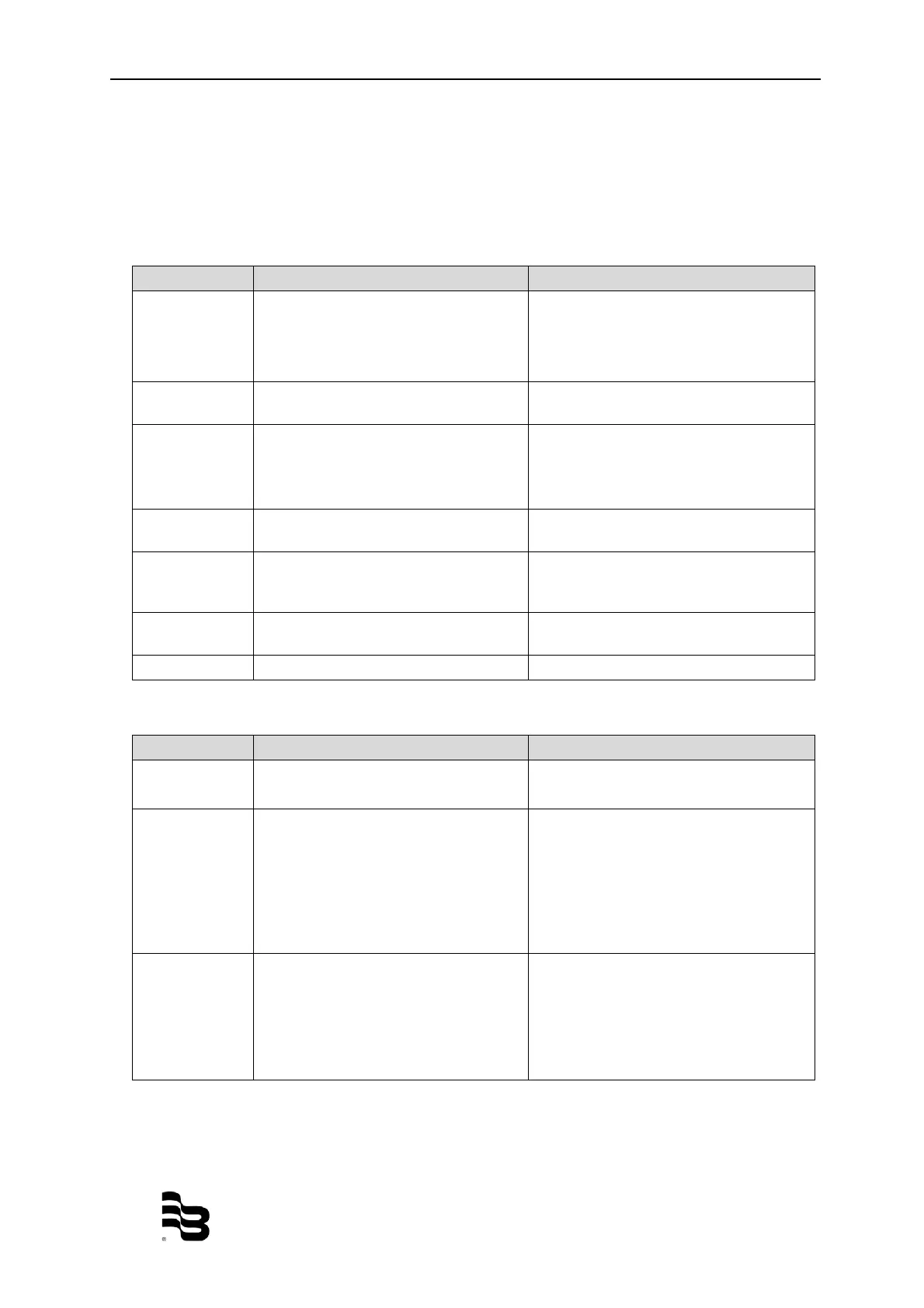

Other error Possible Cause Recommended Action

Meter does not

function

No auxiliary power.

Fuse defective.

Provide auxiliary power.

Replace fuse.

Fluid is flowing,

however

display shows

zero

Signal cable is not connected or

connection is interrupted.

Detector installed opposite to

forward flow direction (see arrow on

type plate).

Connection cable for coils or

electrodes mixed-up.

Check signal cable.

Turn detector by 180°.

Check connection cable.

Inaccurate

measurement

Wrong parameters.

Pipe not completely full.

Check parameters (detector,

amplifier and size) as per annexed

data sheet

Check if measuring pipe completely

full.

Loading...

Loading...