4 P/N 133487

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SC22-3 Safety Controller

Instruction Manual

Overview

1.4 Configuring the Safety Controller

Building a configuration for the Safety Controller is a simple

process, using one of two interfaces: the push buttons and

display on the Controller itself (the Onboard Interface, or OBI) or

the PCI software program included on the enclosed CD

(p/n 134534). The process comprises three main steps:

1. Define the safeguarding application (risk assessment).

• Determine the required devices

• Determine the required level of safety

2. Build the configuration.

• Select safety input device types and circuit connections

• Map each input to one or more safety outputs, or to other

input devices

• Set optional safety output ON- or OFF-time delays

• Select non-safety input device types and circuit connections,

if needed

• Assign status output signals, if needed

• Create configuration name, file name, date, author name,

and notes

3. Confirm the configuration.

• Controller verifies that the desired configuration is valid.

• User confirms that the configuration is what is expected.

1.4.1 Onboard Interface (OBI)

The Safety Controller can be configured using its built-in push

buttons and LCD screen, the Onboard Interface (OBI). The LCD

display provides I/O device and system status information for any

event that causes one or more of the safety outputs to turn OFF.

The display is used in conjunction with the six push buttons to:

• Create or modify password-protected configurations,

• Retrieve fault log information,

• Review device wiring detail and I/O logic relationships, and

• Display I/O device fault details and likely remedial steps.

NOTE: Onboard Interface functions are covered in more detail

in Section 5 and the OBI tutorial, Appendix C.

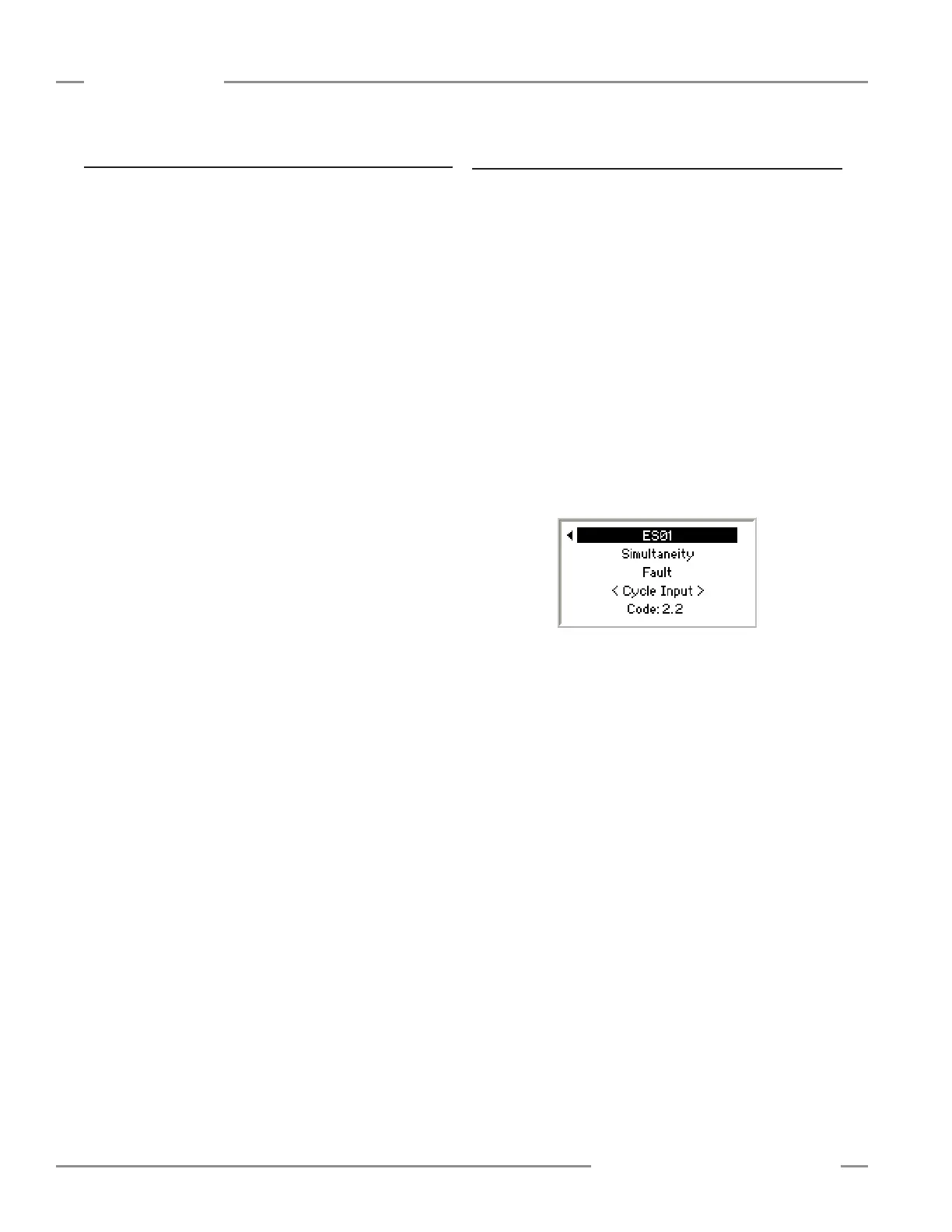

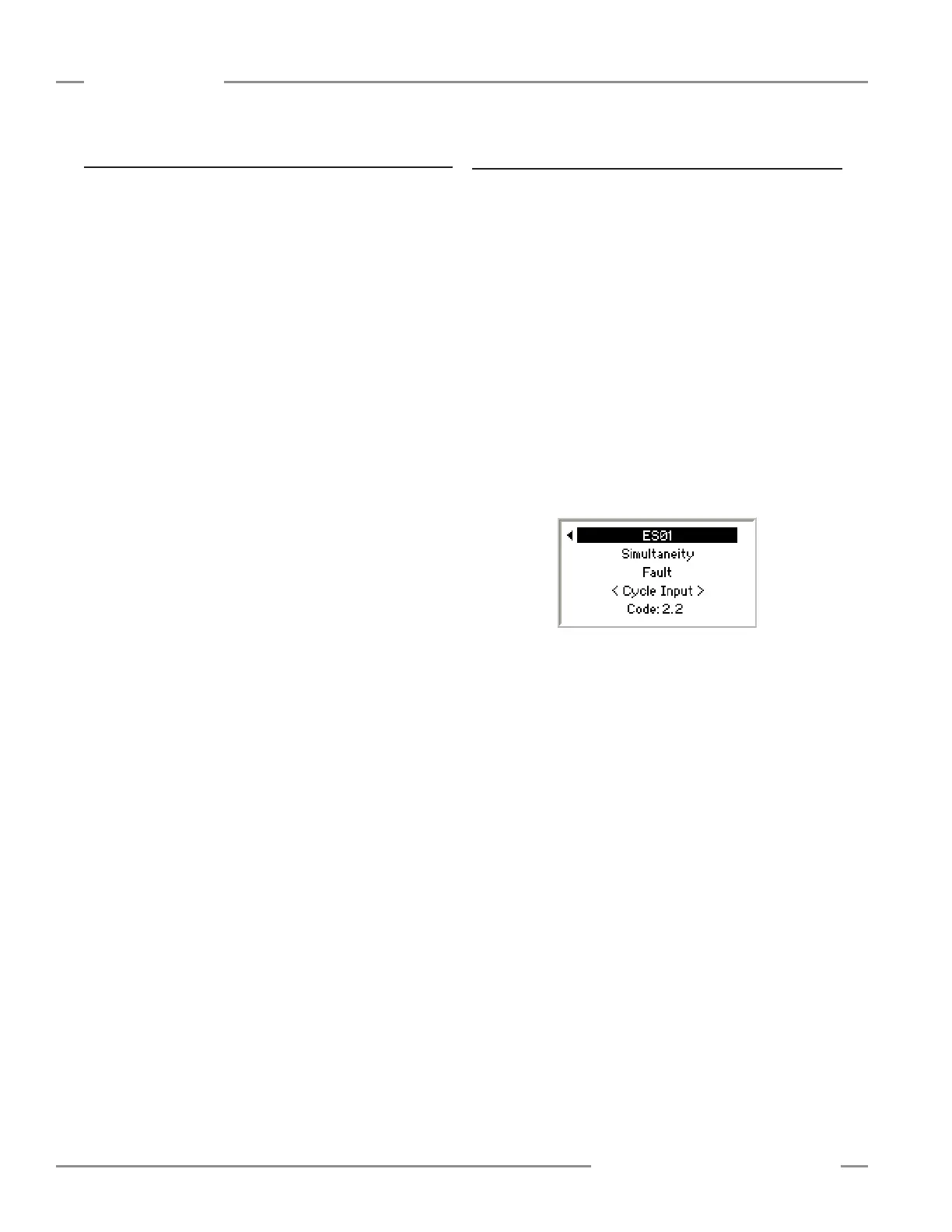

Accessing Fault Codes

The Fault codes are displayed in the last line of the OBI fault

diagnostics menu (see example below). Refer to Sections 5 and

8 for more information.

Loading...

Loading...