10-42

BSWSV

). Of these 4 options,

DPSV

and

OSWSV

are most often used, due to their

good sensitivity and low detection limits, together with their speed of operation. A

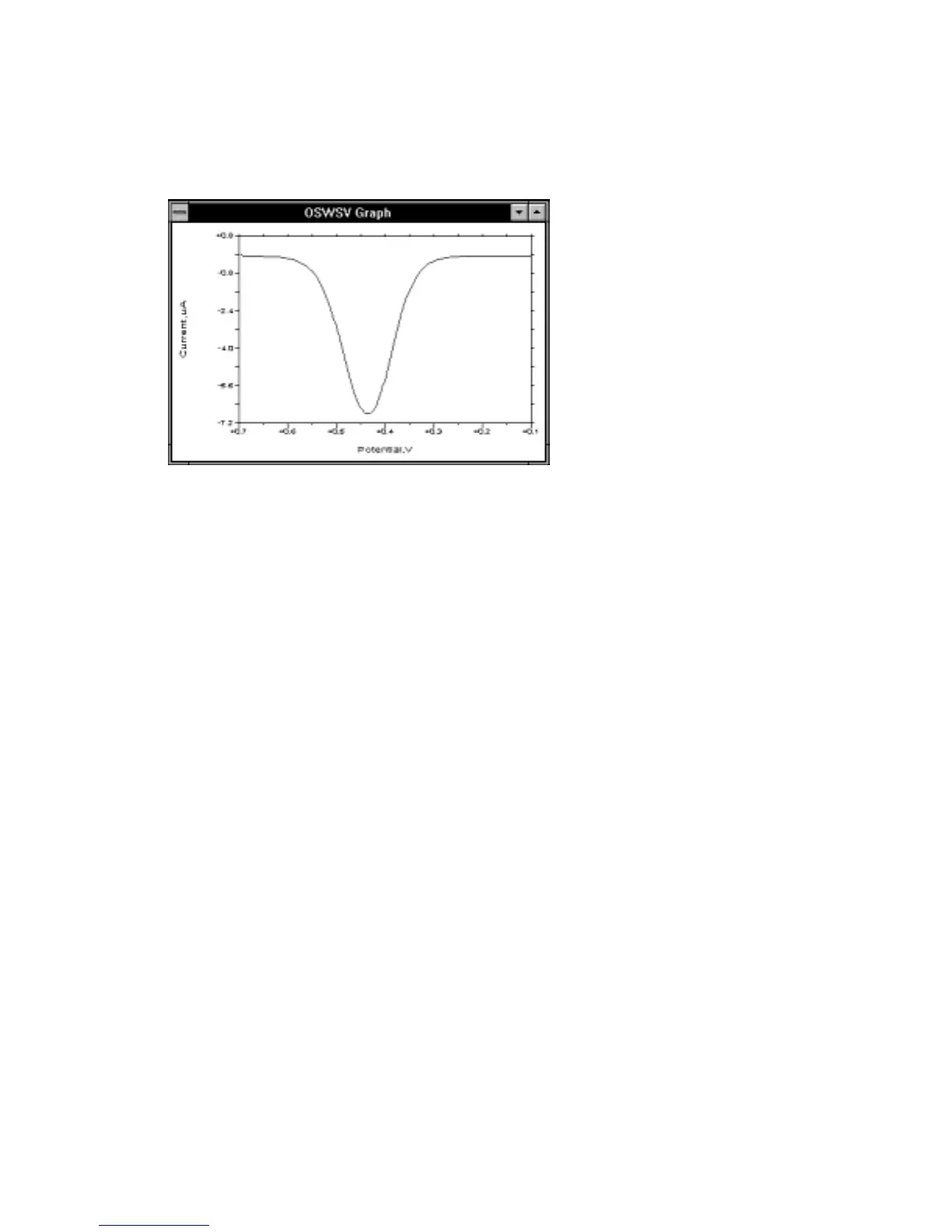

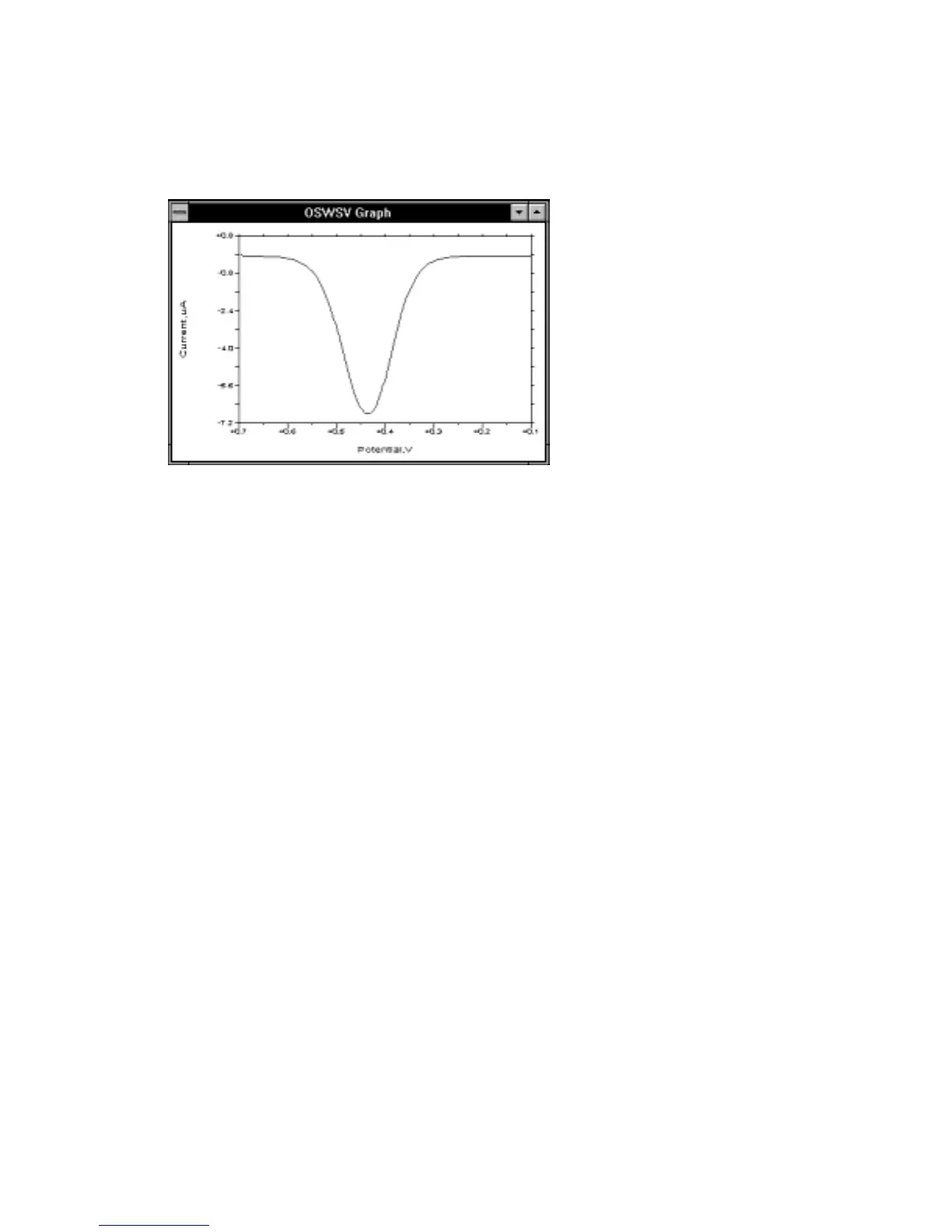

typical current response for the stripping step for

OSWSV

is shown in Figure 10-27.

Figure 10-27.

Typical current response for

OSWSV

.

It is important to note that it is the concentration of lead in the mercury electrode that

is important rather than the concentration of lead in solution. The concentration of

lead in the mercury electrode can be increased (and hence the detection limit of the

experiment lowered) by increasing the

Deposit Time

and/or the stirring rate. The

magnitude of these two parameters depends on the sensitivity of the mercury

electrode, which depends on the surface area to volume ratio (i.e., how many of the

lead atoms deposited are on the surface and detectable in the stripping step). This

ratio is considerably higher for the TMFE, so a shorter deposition time is required

(ca. 1-2 minutes vs. 5 minutes). In addition, faster stirring can be used with the TMFE

due to the relative mechanical instability of the HMDE. The signal resolution is also

better with the TMFE, which can be important when there is more than one metal ion

present.

However, the greater sensitivity of the TMFE can also be a disadvantage, since the

solubility of the metal in the mercury can be exceeded more readily. This can lead to

the formation of intermetallic compounds, which can affect the accuracy of the

experimental results (e.g., shifts in the stripping potential and depression of the

stripping current). One pair of metals that readily combine is zinc and copper.

In order to be of use as a quantitative analytical technique, the results of stripping

experiments must be reproducible. Therefore, experimental conditions must be

reproducible. Great care must be taken in the sample preparation, cleaning of

glassware, etc. The rate of stirring during the deposition step and the condition of the

mercury electrode must also remain constant. The advantage of using the Rotating

Disk Electrode with a TFME is the precise control of the rotation rate; however, it is

easier to obtain a reproducible electrode surface with the HMDE than with the TMFE

Loading...

Loading...