BEKA 2016 All rights reserved!

...a product of BEKA

BAL_2152_EP1_Central grease lubrication pump_0816_EN EDV-Nr. 1090200430

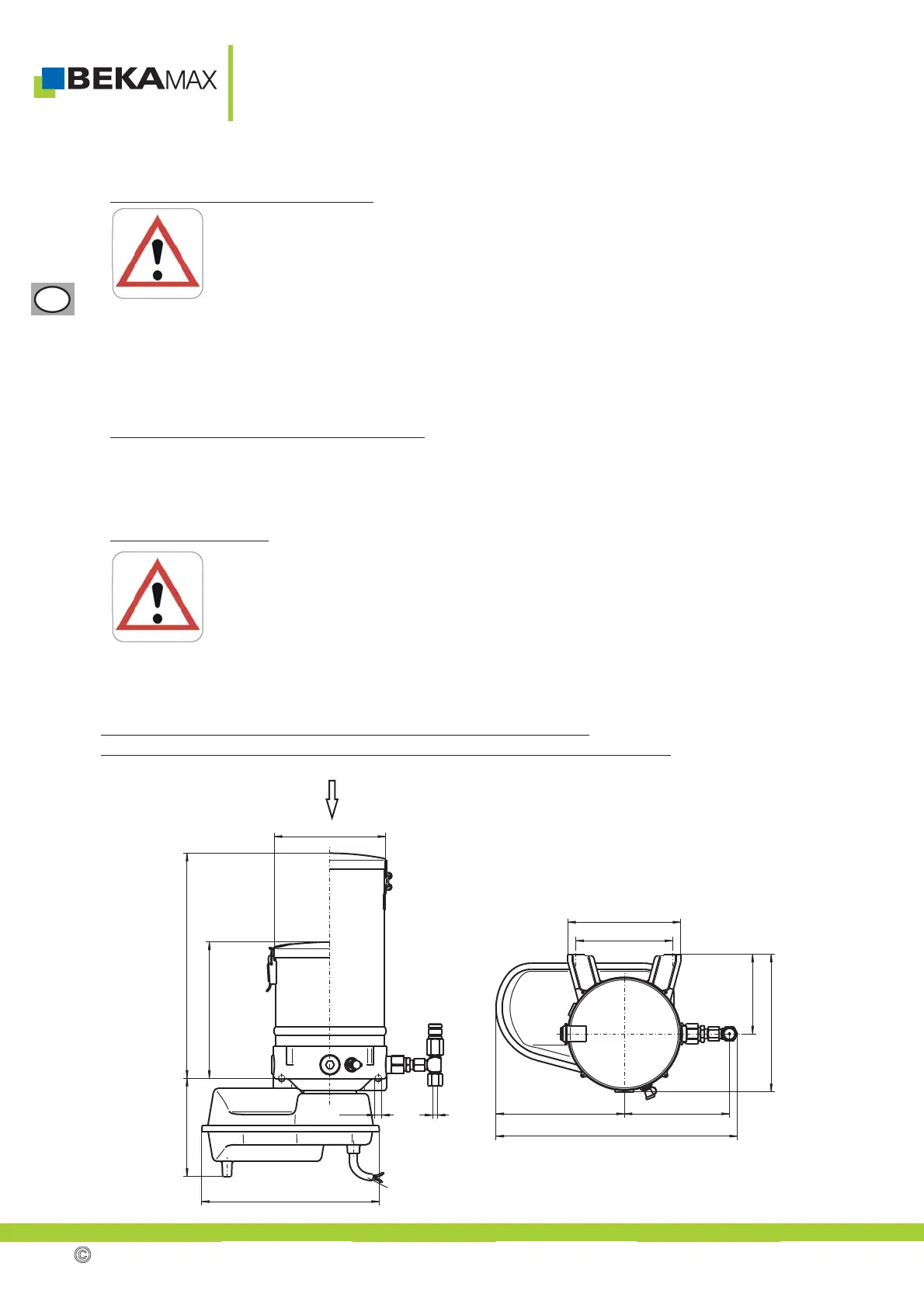

130

152

172 137 5.

321

107

185

Ø150

184

304

137

239

Ø9.5

Pipe

connection

dia.6

“X”

Connecting cable

length 10 m

Model with

4 kg reservoir

Model with

2 kg reservoir

View “X”

6. Overview and installation dimensions:

6.1. Central lubrication pump EP-1 and FKGGM-EP with steel reservoir:

5 Assembly manual.:

The following conditions have to be satisfied during the assembly of this

grease lubrication pump, thus it can be assembled, with other parts, to a

complete machine without affect the safety and health of human.

Set up the grease lubrication pump horizontally on both sides at the place where it has to be

installed! Pay also attention to the mentioned data regarding the fastening bore in the

dimensioned drawing.

Special measures for the noise prevention and for the vibration reduction of the grease

lubrication pump during the installation don't have to be taken.

Pipeline and hydraulic hose line assembly

· Layout must be expert.Assemble free from distortion.

· Comply with the pressure seal tightness of the threaded joints.

· Please observe the permitted pressure range of the pipeline and the hydrauc hose line.

Electrical connection

·

Current supply may only be made by professional electricians

·

The electrical components of the system must be wired expert.

·

Compare the voltage details with the existing mains voltage

10

EN

Loading...

Loading...