BAL_2152_EP1_Central grease lubrication pump_0816_EN EDV-Nr. 1090200430

45

EN

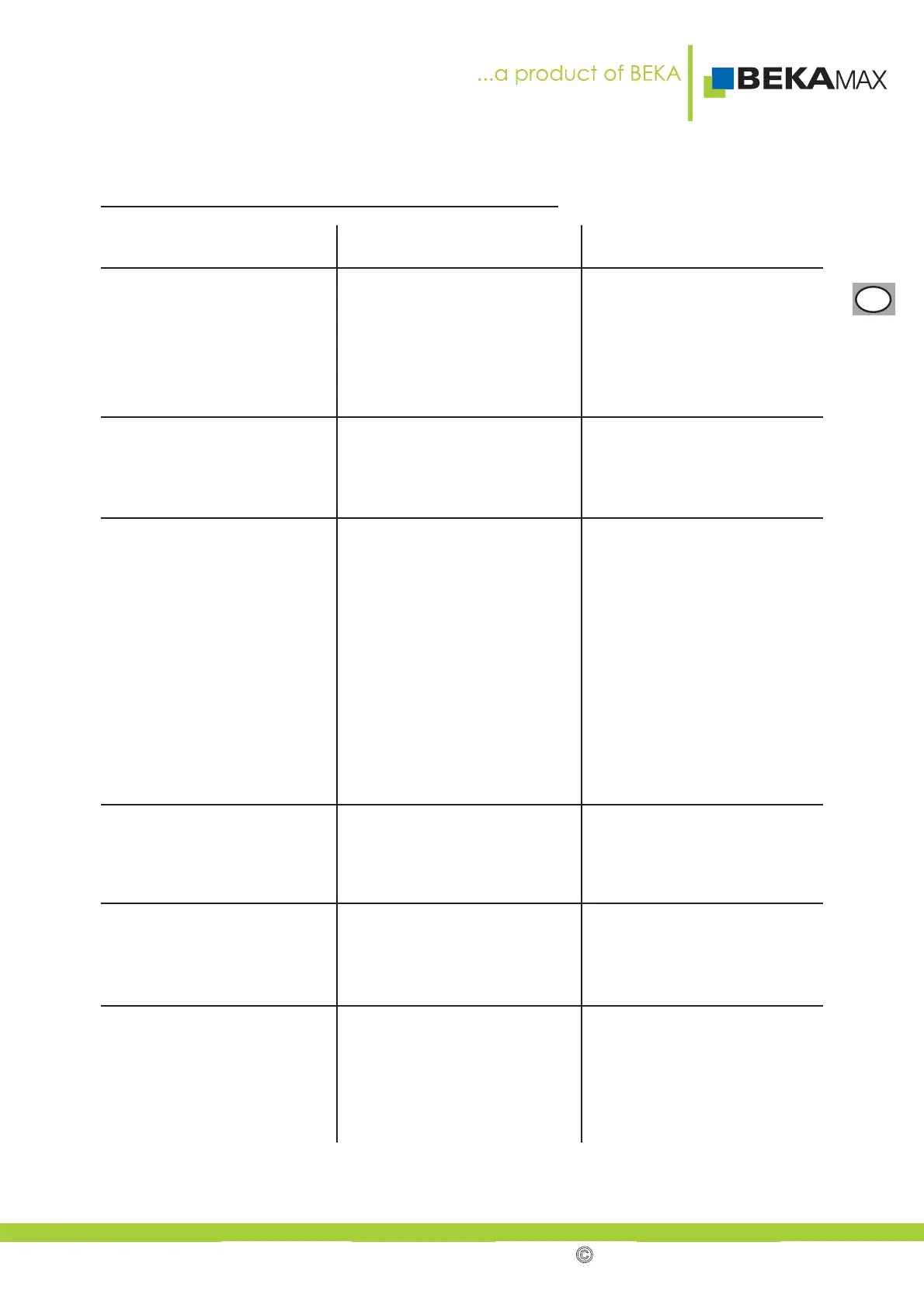

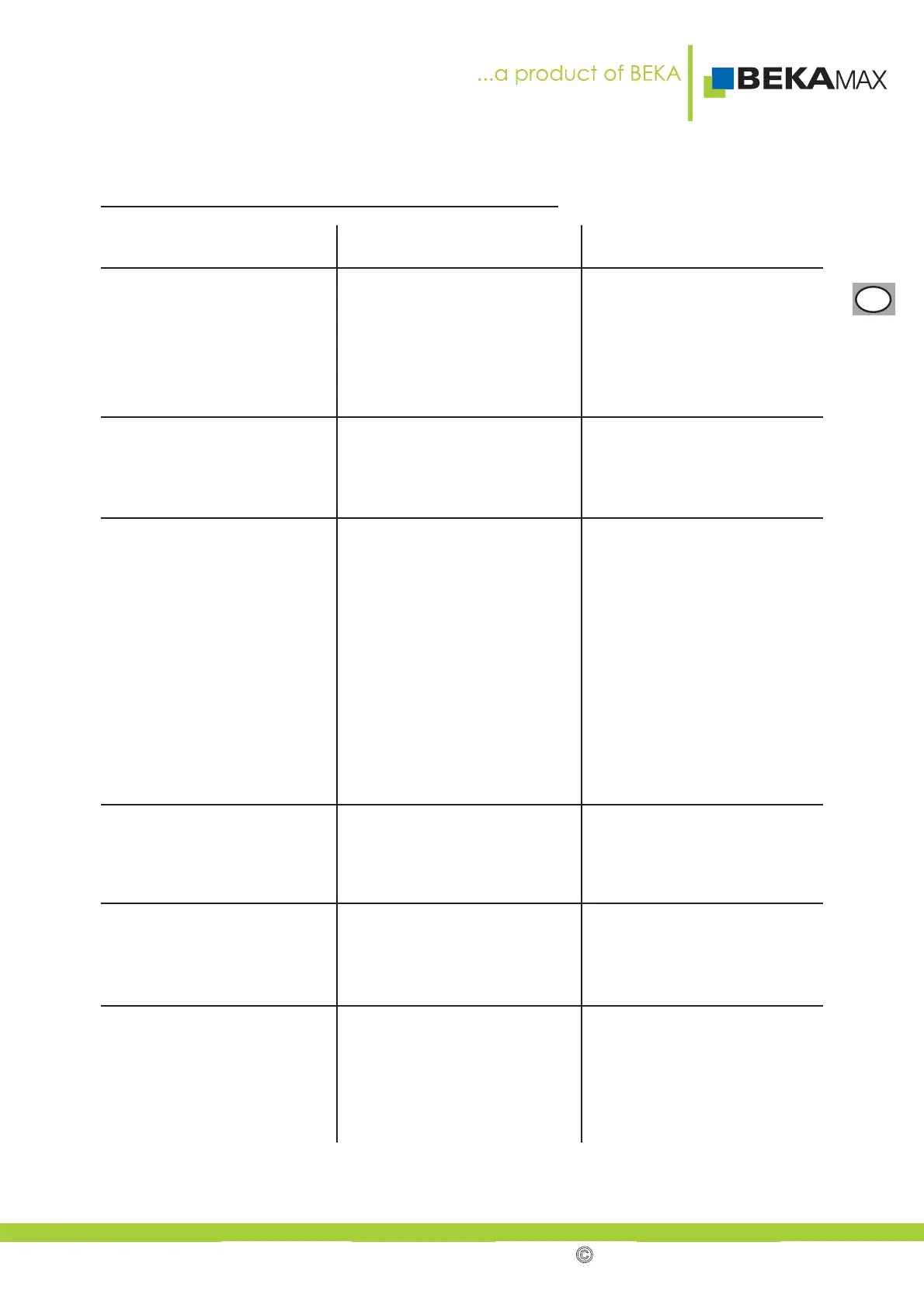

21. Malfunction - Cause - Remedy:

Malfunction

- Pump does not operate

- Pump operates, but does

not supply lubricant

-

No grease collar at all

lubrication points

-

No grease collar at several

lubrication points

- No grease collar at one

lubrication point

-

Reduced pump speed

Cause

- Fuse of unit blown

- Integrated electronic

control defective

- Electrical cable broken

- Pump defective

- Pump element not nested

- Air in the feed piston

- Filling level below

minimum

- Defective pump element

- Pump does not operate

-

Cycle time too long

- Lubrication time too short

- Number of strokes too low

- Number of rotation too low

- Pump element PE-120 V

adjusted too low

- System blocked

- Feed pipes for secondary

distributors burst or leaky

- Fitting leaky

- Appropriate lubrication line

burst or leaky

- Fitting leaky

- High pressure in the

system

- Low ambient temperature

Remedy

-

Replace fuse

-

Replace integrated control

-

Renew electrical cable

-

Replace the pump

-

Renew pump element

-

Ventilate the pump

-

Re-fill the reservoir

-

Renew pump element

-

See „Pump does not

operate”

-

Reduce cycle time

-

Increase lubrication time

-

Increase number of

strokes

-

Increase number of

rotations

-

Adjust pump element

-

See „Leakage of grease

at the pressure relief

valve“

-

Renew the pipe

-

Re-tighten or renew the

fitting

-

Renew the pipe

-

Re-tighten or renew the

fitting

-

Check system / bearing

points

-

Not defectiveness

(1 or 2 intermediate

lubrication cycles might be

useful)

BEKA 2016 All rights reserved!

Loading...

Loading...