32

4 - CONNECTIONS

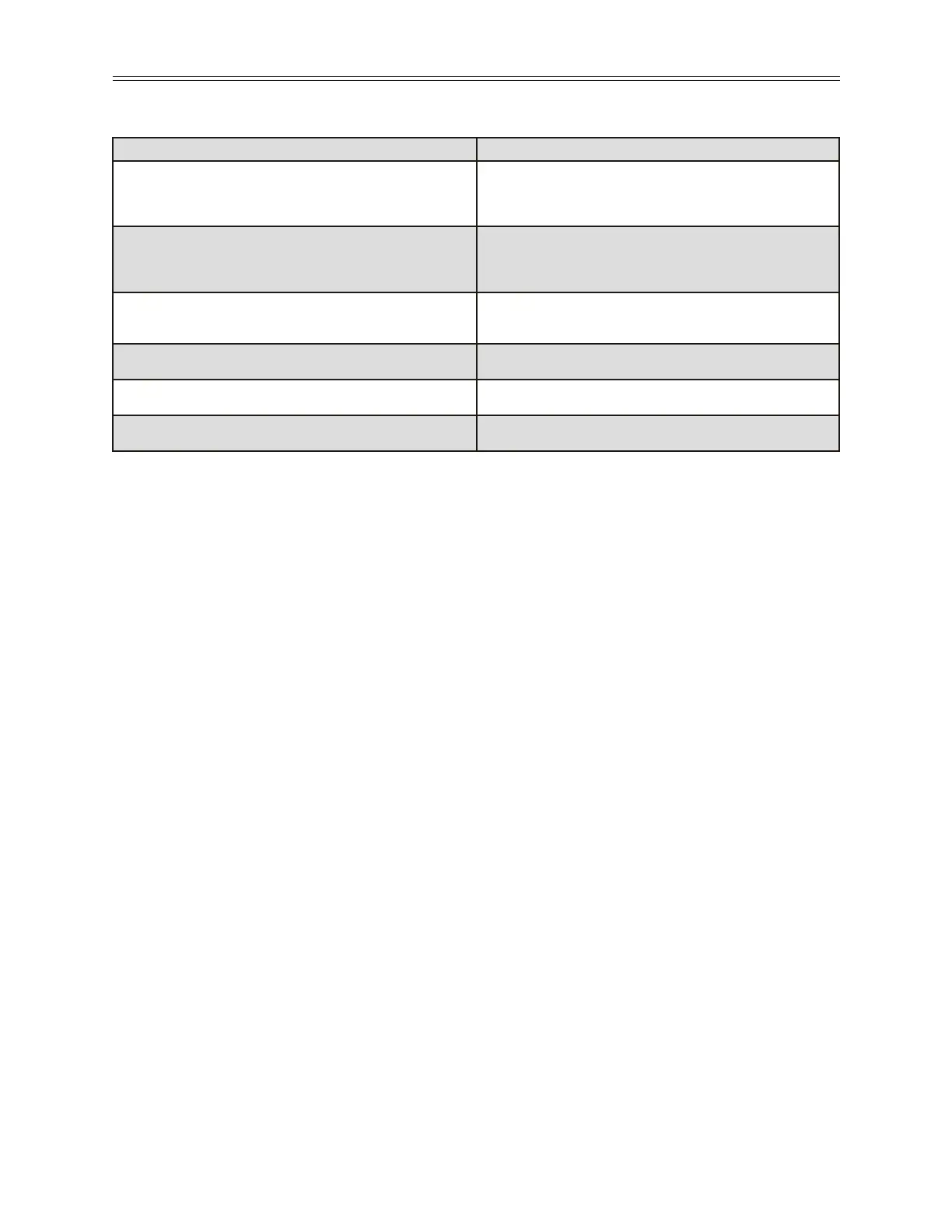

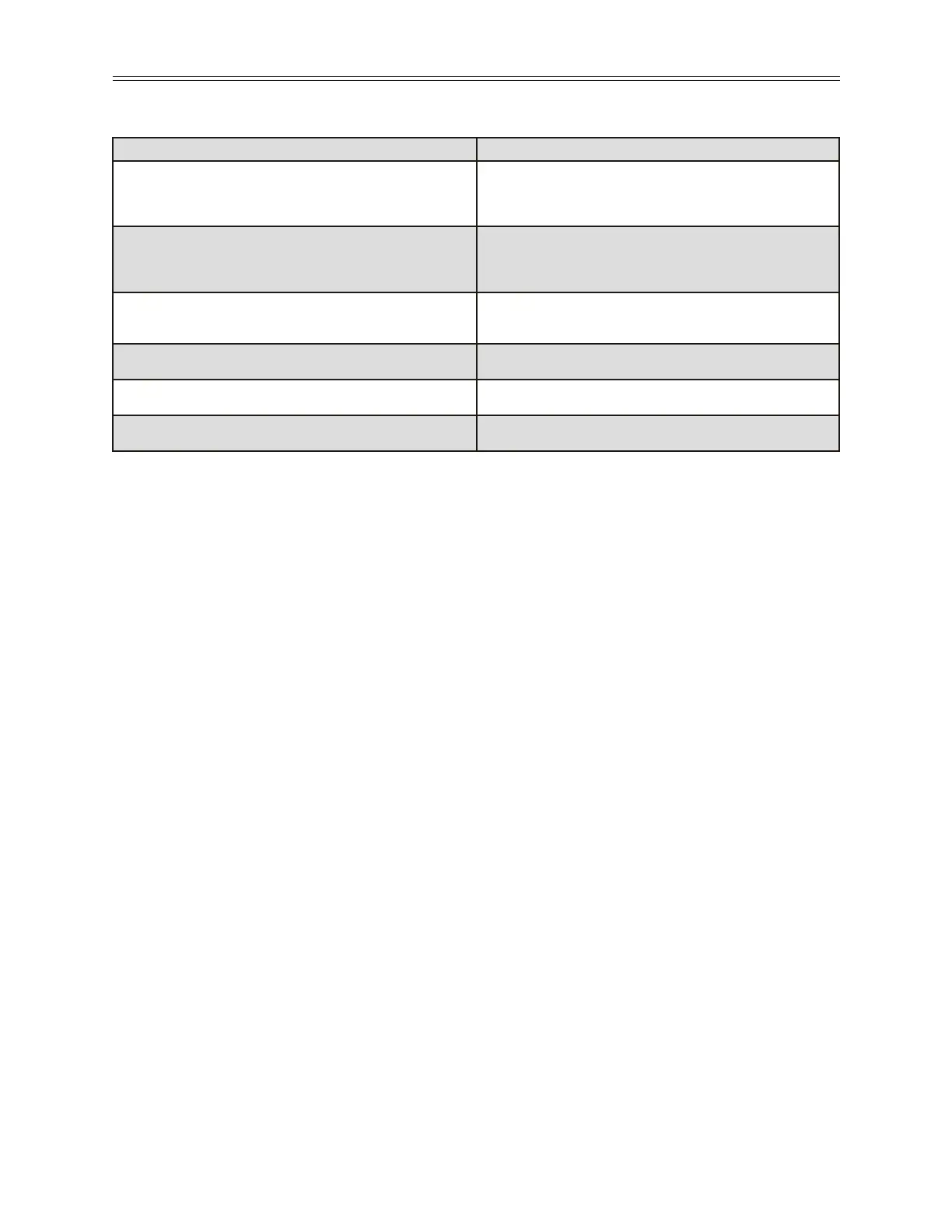

See table below for a summary of power terminal wiring specications.

z NOTE: Wire type not specied by the manufacturer. Some types of wire may not t within the

constraints of the conduit entry and bend radius inside the drive.

4.1.4 Grounding and Ground wire sizes

The drive contains high power and high frequency switching devices, leakage current may ow •

between the drive and ground. Ground the drive to avoid electrical shock.

Connect only to the dedicated ground terminal of the drive. Don’t use the case or chassis screw for •

grounding.

If multiple drives are installed near each other, each must be connected to ground directly. Take care •

not to form a ground loop between the drives and the grounding location.

The protective earth conductor must be the rst one in being connected and the last one in being •

disconnected.

The grounding wire conductor size shall comply with all local regulations. The ground wire shall be as •

short as possible and should be connected to a ground point as near as possible to the drive.

S4 Size / Models (Frame #)

Specications

Frame 0

12 in-lbs nominal torque or

13 in-lbs maximum torque

12-24 awg wire

5/16” (0.3125’) strip length

Frame 1

16 in-lbs nominal torque or

18 in-lbs maximum torque

8-18 awg wire

5/16” (0.3125”) strip length

Frame 2

30 in-lbs nominal torque

6-8 awg wire

3/8” (0.38”) strip length

Frame 3

35 in-lbs nominal torque

3 awg wire

Frame 4

65 in-lbs nominal torque

3/0 wire max

Frame 5

132 in-lbs nominal torque

250MCM wire max

Loading...

Loading...