40 82.503 TRACKER / TRACKER-S D.P.A

- By cleaning your sprayer regularly during and at the end of treatment seasons:

- You will avoid spraying chemical residues on the crops,

- you will ensure a good distribution of the product, while eliminating total or partial blockage of the

nozzles,

- you will increase your sprayer's life.

PRACTICAL RECOMMENDATIONS FOR

THE SERVICING OF YOUR SPRAYER

Carry out the sprayer's maintenance operations with the engine switched

off, the ignition off and the power take-off disconnected.

- If this occurs, reduce the PTO revs to less than 540 rpm or add an anti-foaming additive to the contents of

thetankwhenlling.

Do not add fuel oil to the spraying mixture as an anti-foaming agent.

FOAMING IN THE TANK

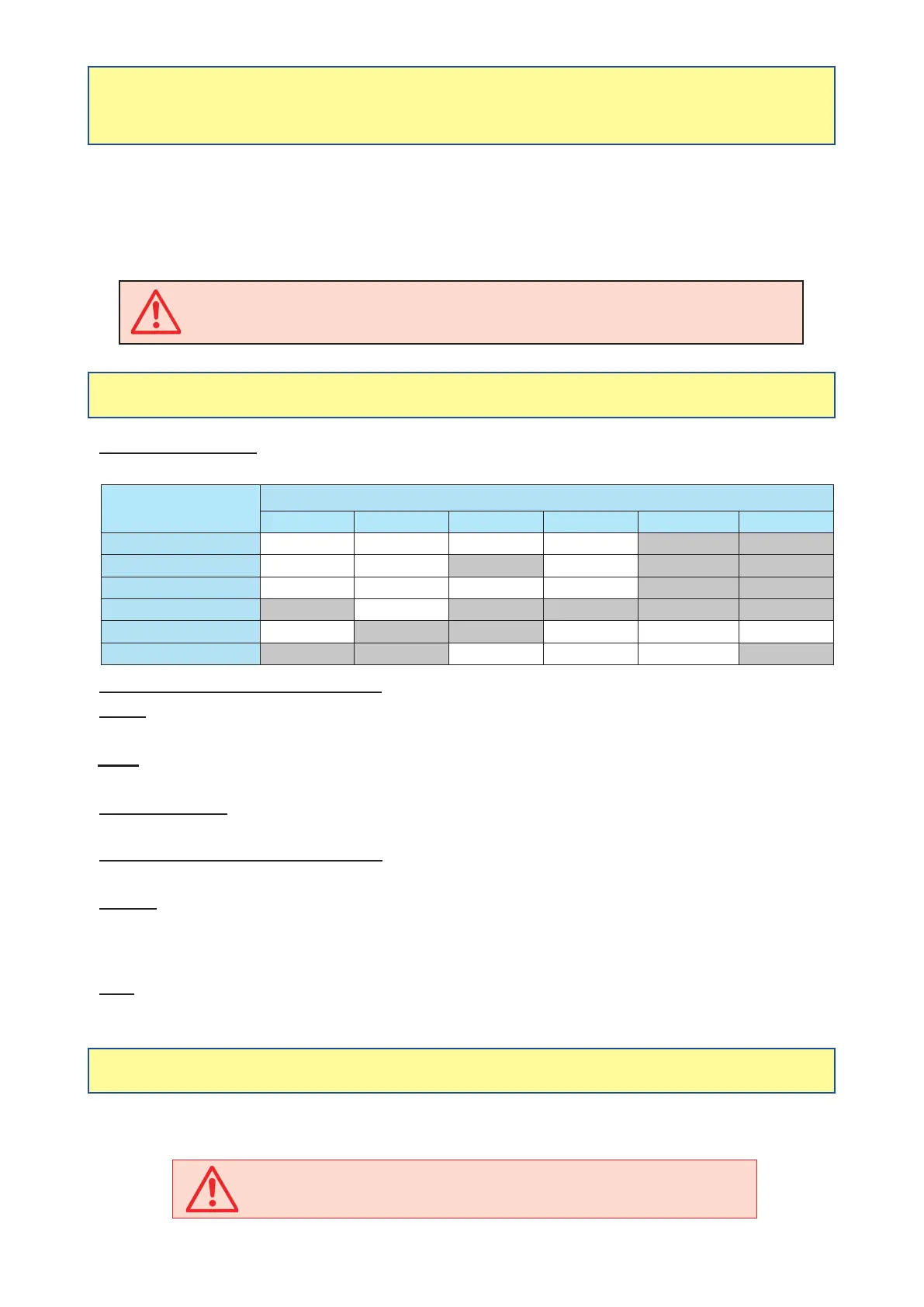

- Check tyres pressure:

- See table below.

TYPE OF TYRE

PRESSURE IN BAR

KLEBER MICHELIN TAURUS ALLIANCE CONTINENTAL MITAS

230/95 R48 3.6 4 4 4

270/95 R48 3.6 3.6 4

300/95 R46 3.6 3.6 3.8 3.6

380/90 R46 3.6

420/85 R38 1.7 2 1.6 1.6

460/85 R38 1.6 1.6 1.8

- Checkthetightnessofthewheelbolts.

- Filters:

-Makesurethatthesuctionanddeliverylteriscleanandingoodcondition.

- Pipes:

- Look for any leaks, check for kinks in the pipes.

- Sealsandttings:

- Check to ensure that nuts and connectors are tightened, change the seals if necessary.

- Pump, bevel gearbox, speed multiplier:

- Check the oil levels.

- Nozzles:

-Tochangethenozzlesonceperyearorwhentheirowrateis10to15%greaterthantheirinitialow

rate. To do this, use the FLOW TEST - BERTHOUD reference 765.241, or the FLOW RATE GAUGE -

BERTHOUD reference 778.887.

- Tank:

- Check that there is no foreign matters inside the tank.

CHECKS BEFORE SPRAY SEASON

Loading...

Loading...