42 82.503 TRACKER / TRACKER-S D.P.A

NOZZLES OR FILTERS DIRTY

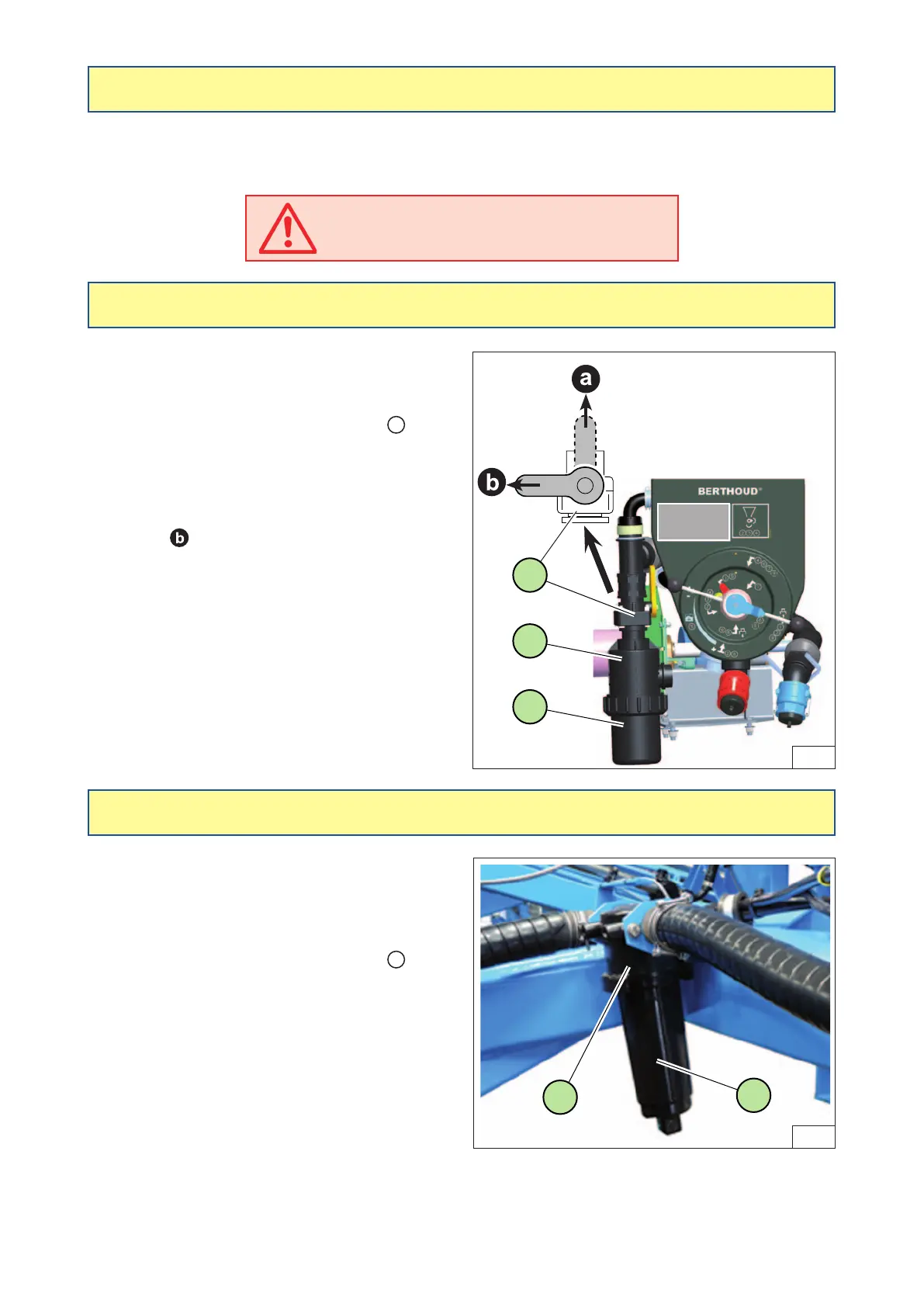

DELIVERY FILTER (gure34)

Never blow into a nozzle.

-Cleanandrinsedirtyltersornozzlesusingabrushandwater.

To do this, use the brush/wrench BERTHOUD reference 779.354

-Thedeliverylter(1)islocatedatrearofthesprayer,

after the main tank.

-Itprovidesadditionalltration.

-Tocleantheltercartridge(2)ofthedeliverylter

(1), you must put the indexes on function

of the

Berlogic (see page 25).

- Before each intervention on the delivery lter, you

must isolate the circuit and open the suction lter

(see procedure above) to remove the pressure.

-To remove the lter cartridge, unscrew the lter

body (2) of the delivery lter (1) using a 27 mm

wrench (wrench not supplied with the sprayer).

The lter cartridge needs to be cleaned after

each application. Grease the seals.

Reminder: The original factory-installed lter cartridge mesh is 4/10 (8/10 mesh is available separately

for liquid fertilizer).

1

2

34

1 EXTERNAL SUCTION

2 WA TER INTA KE, MAIN T A NK

3 WA TER INTA KE, EXTERNAL SUCTION

4 WA TER INTA KE, RINSING TANK

5 SPRAYING

6 TA NK CLEANING WITH RINSING TANK

7 BOOM RINSING WITH RINSING TANK

8 TRANSFERRING

9 FILT ER CLEANING

10 AUXILIARY SUCTION OPTION

11 EXTERNAL W A SHING OPTION

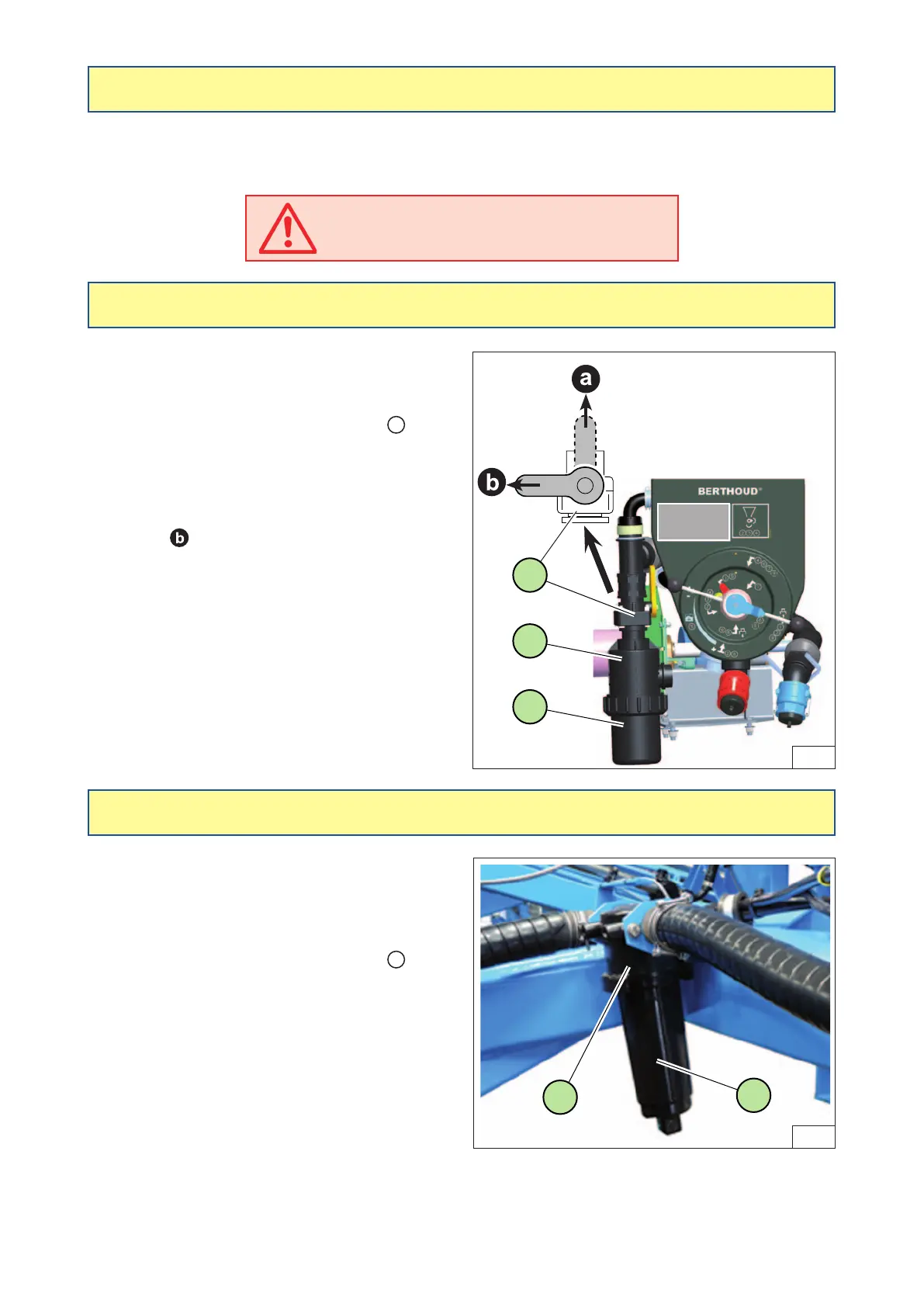

SUCTION FILTER (gure33)

- The suction filter (2) is located at the control

station.

-To clean thelter cartridge (3) of thesuction lter

(2), you must put the indexes on function

of the

Berlogic (see page 25).

-Toremovetheltercartridge(3)ofthesuctionlter

(2), you must rst isolate the circuit.

- To do this, put the handle of the valve (1) in

position

. The filter cartridge (3) is then

accessible.

2

3

33

1

Loading...

Loading...