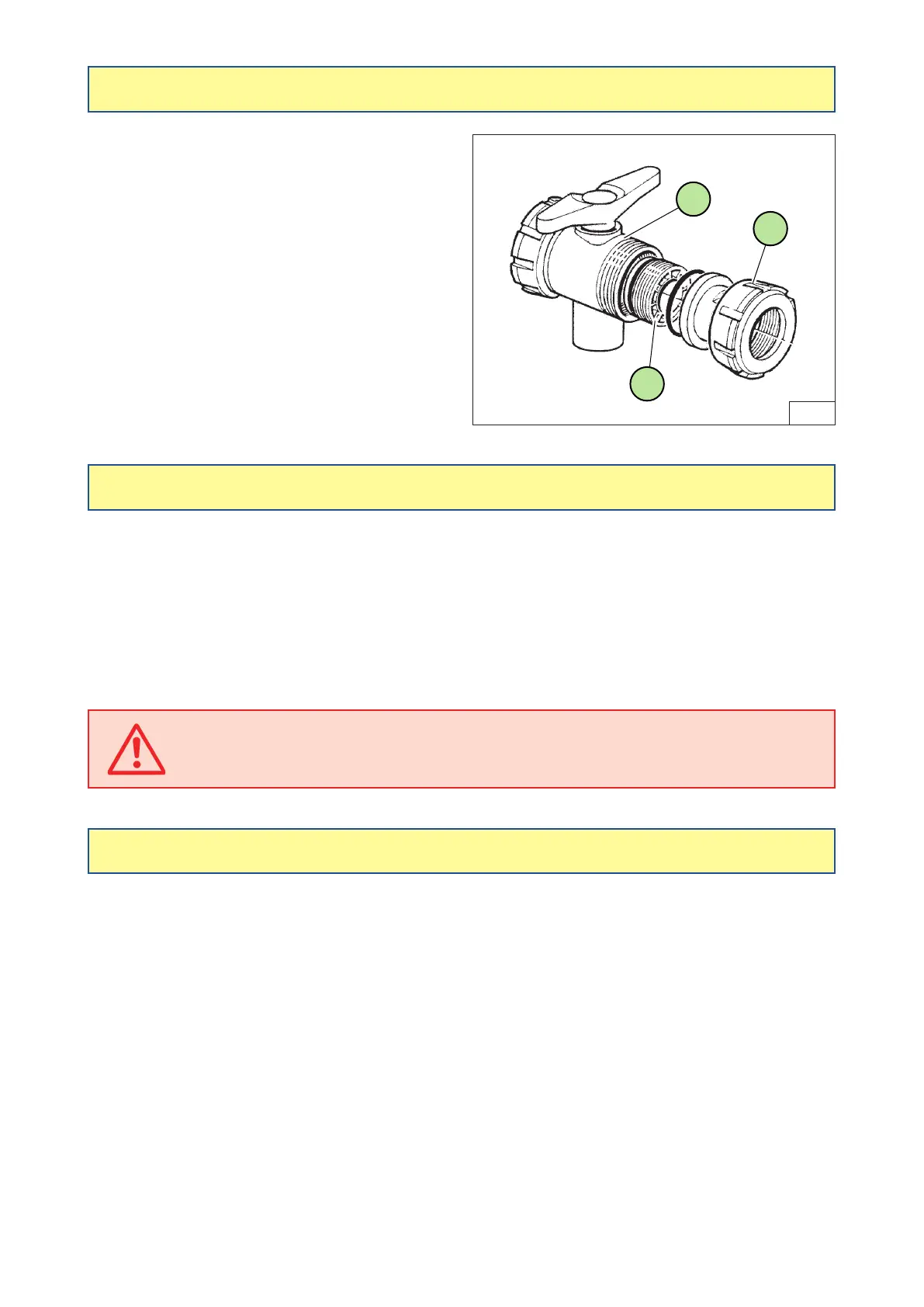

82.503 TRACKER / TRACKER-S D.P.A 43

35

- The solvents in the mixtures can cause some seals

to swell.

- If, in spite of good maintenance, the ball valves should

become blocked, it is possible to unblock them simply

by doing the following:

▪ Unscrew the two nuts (2) to access the internal

adjustment part (3).

▪ Unscrew the internal adjustment part (3) by

1/8 of a turn, until the spherical ball turns normally,

without great effort.

▪ Reassemble the parts in reverse order and check

the valve is tight.

MAINTENANCE OF PLASTIC VALVES (gure35)

For further information about the spray boom, refer to its technical documentation

located in the blue information pouch provided with the sprayer.

- After each use, rinse the pipe work thoroughly, operating the sprayer for several minutes with clear water.

- Drain the pipe work, particularly if there is a risk of frost.

- After cleaning the boom with a high-pressure jet, grease the ram shafts to prevent all risk of corrosion.

-Keepthehingesonthearms,thebearingsurfacesofthehingecamandtheuprightsonthexedframe

greased.

- Touch up the paintwork as necessary.

SERVICING THE BOOM

- With the delivery and prior to each treatment season, 1 hour after use, after 1 day and then periodically, and

to check the tightening of the nuts:

- The wheel bolts,

- the axles fastening,

- the coupling fastening.

- Once a year:

- Check the play of the bearings and their greasing,

-dustthebrakeassemblyandcheckthewearofthettings,

- adjust the travel of the brake lever,

- replace the pin of wheel axle nut every time it is disassembled.

- In case of intensive use, carry out these operations every 3 months.

TIGHTENING TORQUES OF WHEEL NUTS

- Ø 18: 400 to 420 Nm.

CHECKING NUT TIGHTNESS

1

2

3

Loading...

Loading...