Installation, Operation and Maintenance Manual

September 2019

MAN720_IMVS2000v2_IOM Rev. 6

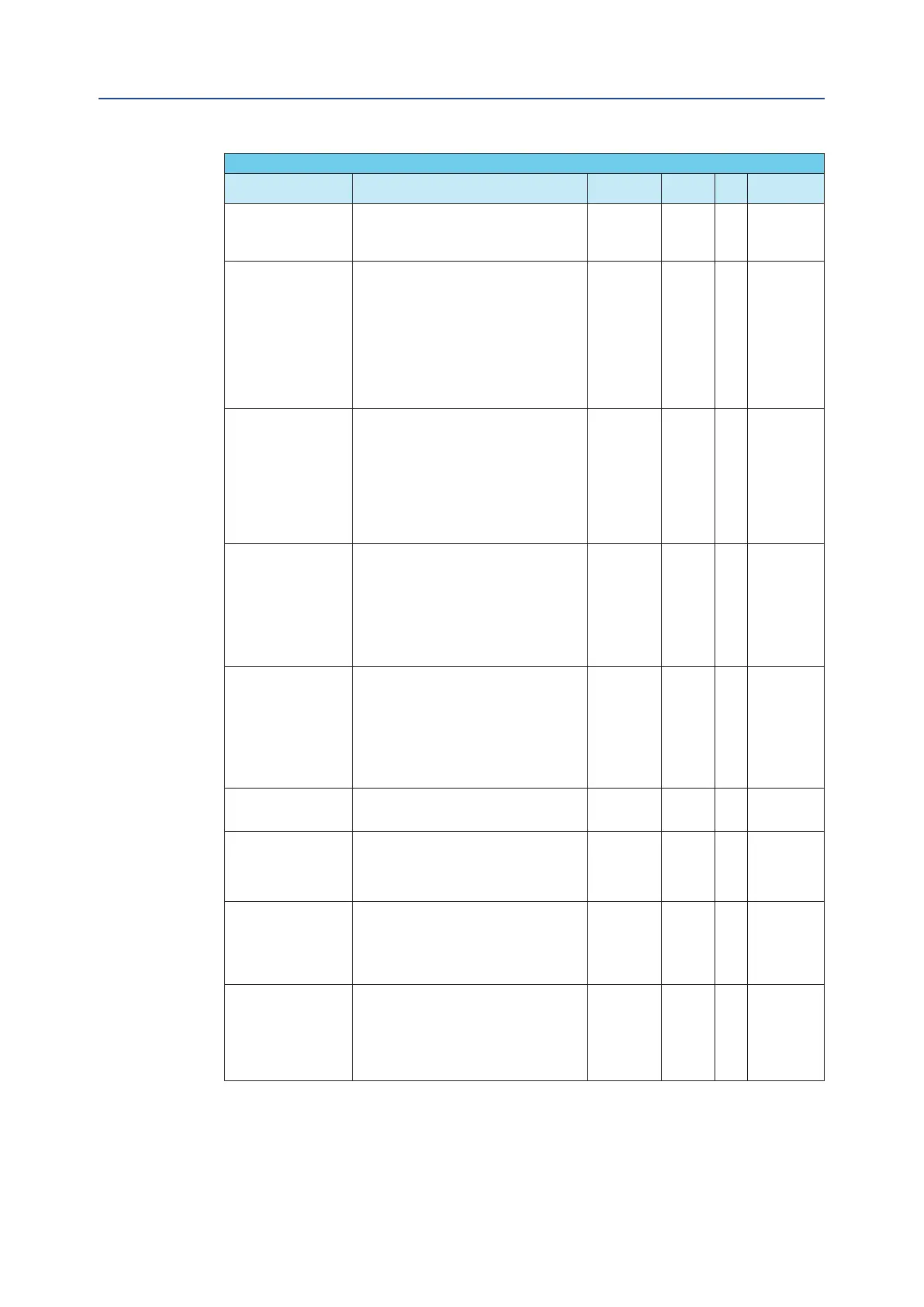

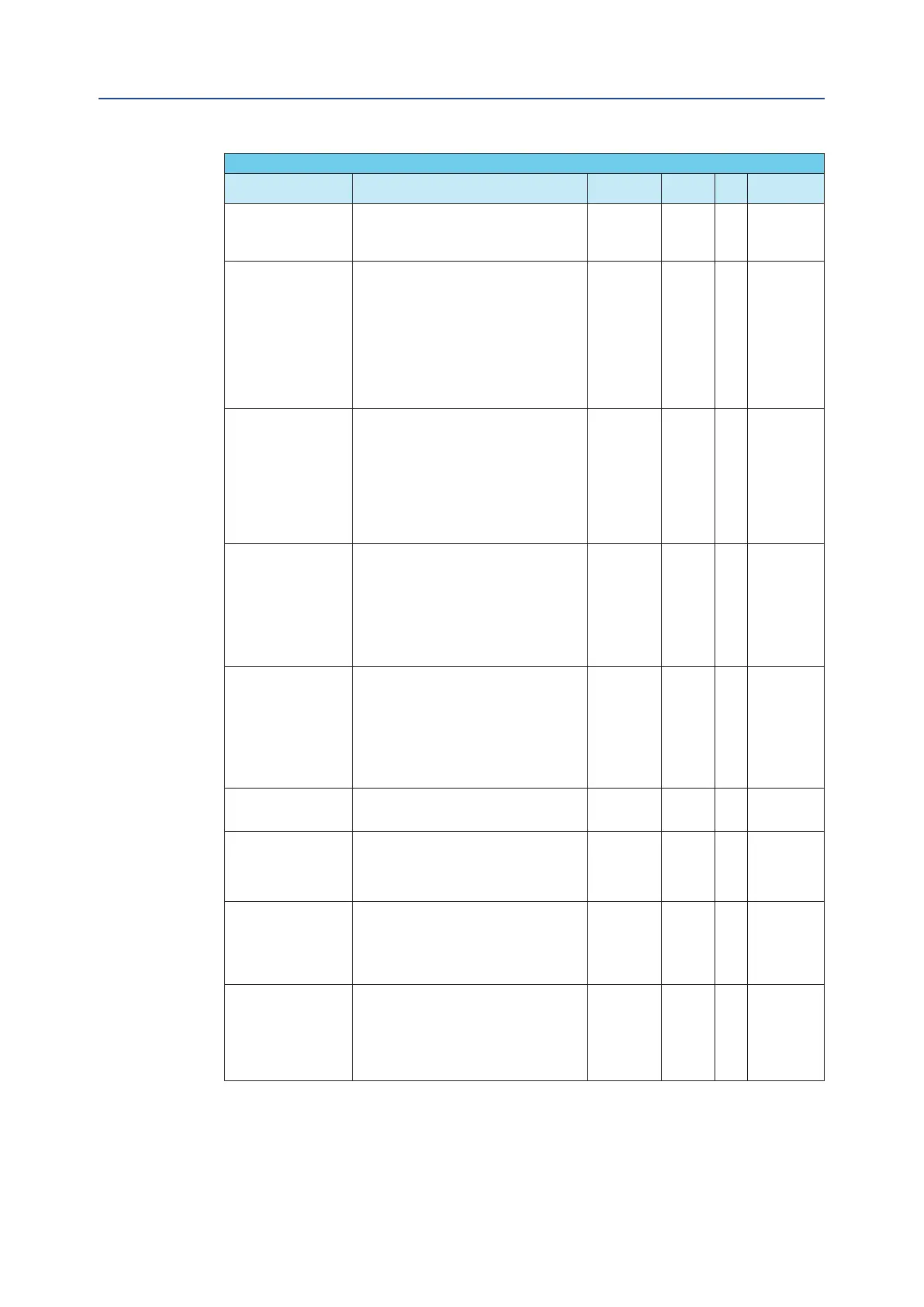

Section 6: Conguration Parameters

Conguration Parameters

PARAMETERS OF THE “VIEW/SETUP MODE” MENU

PARAMETER NAME DESCRIPTION RANGE

DEFAULT

VALUE

R/W

(1)

AVAILABLE

ON (2) (3)

Sign. En.

(Signatures Enabled)

If it is set as “Yes” it is possible to perform com-

mands “Baseline Signature” and “Maintenance

Signature” otherwise they do not work.

Yes, No Yes R/W

Local, Serial,

Bus

Op. Pos. %

(Open Position Hyster-

esis)

It defines the tolerance for considering the actua-

tor/valve as open (it can be “masked” by the Closed

Position Hysteresis).

Its value affects the “OPEN” Digital Output (see

DOs for details) and the activation of the OPOS

alarm (see Section 8 for details).

It affects the validity of the PST (PSSR Alarm) and

FST starting points and if set to a value different to

default one it could influence the PST and

FST results.

0 – 90.0 % 3% R/W

Local, Serial,

Bus

Cl. Pos. %

(Closed Position Hys-

teresis)

It defines the tolerance for considering the actua-

tor/valve as closed. Its value affects the “CLOSED”

Digital Output (see Section 5.2.3 for details) and

the activation of the CPOS alarm

(see Section 8 for details).

It affects the validity of the PST (PSSR Alarm) and

FST starting points and if set to a value different

to default one it could influence the PST and FST

results.

0 – 90.0 % 3% R/W

Local, Serial,

Bus

Op. Time %

(Opening Time Hys-

teresis

It defines the tolerance for the generation of the

following alarms: SOBT, FOBT, SOTT and FOTT.

See Section 8 for details.

This parameter affects the “duration” of the Open-

ing FST time window. It is suggested to perform

a new “Baseline Signature” after changing this

parameter to better compare the next Signatures

and FSTs.

0 -200% 20 % R/W

Local, Serial,

Bus

Cl. Time %

(Closing Time Hyster-

esis)

It defines the tolerance for the generation of the

following alarms: SCBT, FCBT, SCTT and FCTT.

See Section 8 for details.

This parameter affects the “duration” of the Closing

FST time window. It is suggested to perform a new

“Baseline Signature” after changing this parameter

to better compare the next Signatures and FSTs.

0 -200 % 20 % R/W

Local, Serial,

Bus

FST. Pr. %

(FST Pressure Hyster-

esis)

It defines the tolerance for the generation of the

following alarms: OHBP, OLBP, CHBP and CLBP.

See Section 8 for details.

0 -100 % 20 % R/W

Local, Serial,

Bus

H. Pr. Lim.

(High Pressure Limit)

It is applicable only if “Act. Mode” ≠ “Double”.

It defines the threshold for the generation HSP

alarm. See Section 8 for details.

The pressure measurement unit (bar or psi) is deter-

mined by the setting of the “Pres. M.U.” parameter.

0 – 400 bar

(0 – 5800 psi)

400 bar

(5800 psi) R/W

Local, Serial,

Bus

L. Pr. Lim.

(Low Pressure Limit)

It is applicable only if “Act. Mode” ≠ “Double”.

It defines the threshold for the generation LSP

alarm.

See Section 8 for details.

The pressure measurement unit (bar or psi) is deter-

mined by the setting of the “Pres. M.U.” parameter.

0 – 400 bar

(0 – 5800 psi)

0 bar

(0 psi)

R/W

Local, Serial,

Bus

H. Proc. L.

(High Process Pressure

Limit)

It is applicable only if the Process Pressure Sensor

is present (“Proc. S” is not set to “None”). It defines

the threshold for the generation HPP alarm.

See Section 8 for details.

The pressure measurement unit (bar or psi) is deter-

mined by the setting of the “Pres. M.U.” parameter.

0 – 400 bar

(0 – 5800 psi)

400 bar

(5800 psi) R/W

Local, Serial,

Bus

41

Loading...

Loading...