MKF / MKFT (E5) 04/2022 page 86/176

12.3 Over/under temperature safety device class 2 (option)

Example: MKF 56

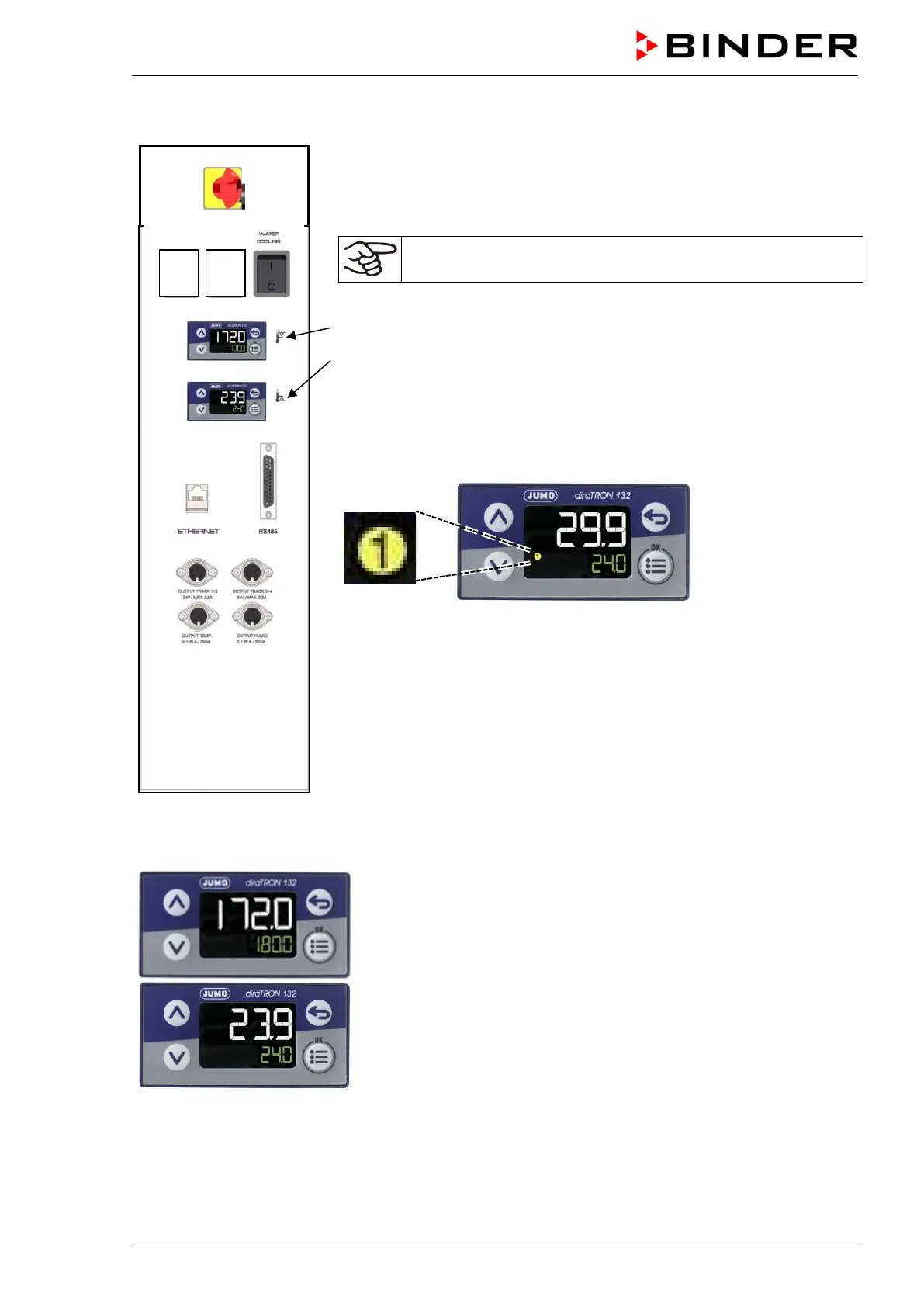

The over-/under temperature safety device (4) consists of two entry modules

(4a) and (4b) located in the lateral control panel. Both modules can be set

from -50 °C / -58 °F (MKF) / -80 °C / -112 °F (MKFT) up to 200 °C / 392 °F

and serve to define the maximum high and low temperature limits.

With this option, the safety controller (chap. 12.2) must be set to

maximum temperature.

(4a) Upper module: Entry of higher limit temperature.

(4b) Lower module: Entry of lower limit temperature.

When the temperature inside the chamber leaves this tolerance bandwidth,

the temperature control, and herewith the heating and refrigeration, are

turned off permanently.

At the corresponding entry module, the pilot lamp “1” lights up.

The controller displays the alarm message “Temp. safety device” (chap.

11.1.2). Additionally, there is an audible alert, provided that the buzzer has

not been deactivated (chap. 11.4).

Let the chamber heat up or cool down to the defined safety temperature

range.

Then reset the alarm message on the controller (chap. 11.3). to re-activate

the chamber. The pilot lamp “1” goes off

as soon as the temperature will

again be below / above the threshold.

Setting limit temperatures at modules (4a) and (4b):

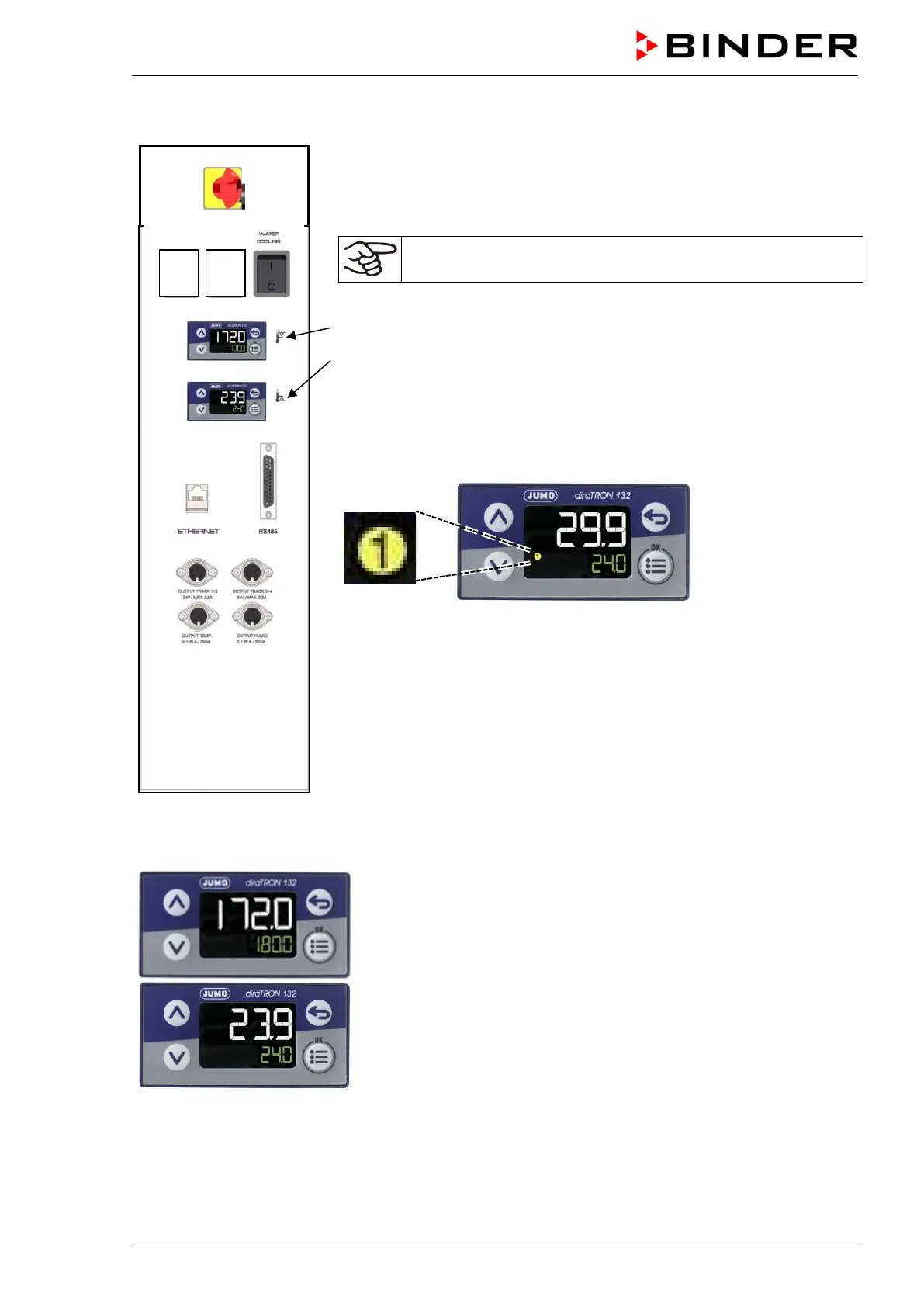

The upper line shows the actual temperature. The bottom line shows

the set-point of the limit temperature.

• Press the arrow-up or arrow-down key

The display changes to entry mode: The set-

line flashes

• Enter the desired limit temperature via the arrow keys and confirm

with the “OK” button.

• Press the Back button.

The set-point in the bottom line stops flashing.

Function check:

Check the over/under temperature safety device class 2 at appropriate intervals for its functionality. It is

recommended that the authorized operating personnel should perform such a check, e.g., before starting

a longer work procedure.

Loading...

Loading...