Menu structure

Control 8313 – 6720859567 (2017/03)

20

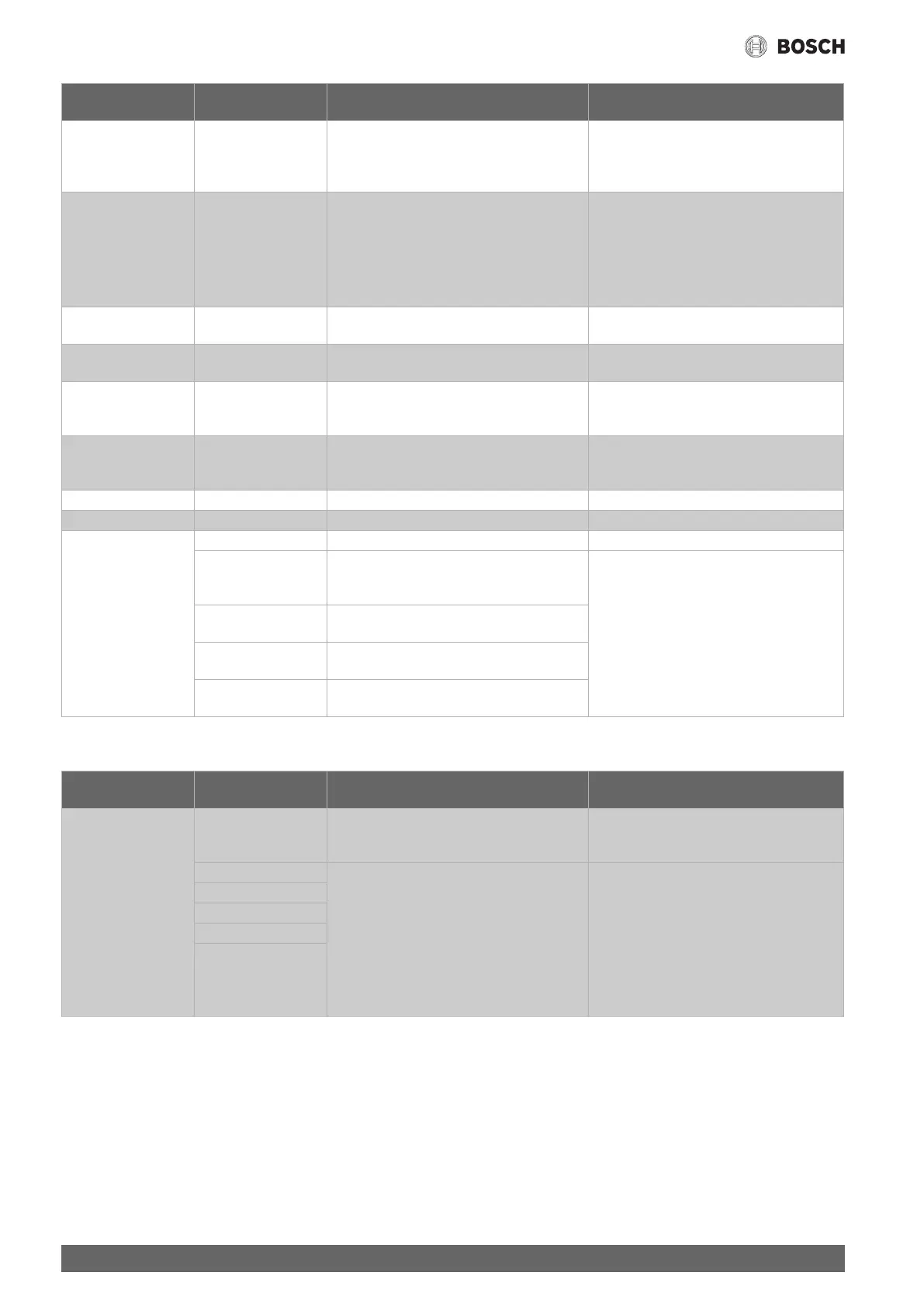

Table 8 Boiler characteristics menu

9.3.2 Settings of the safety equipment

Table 9 Safety equipment settings

External Heat Detection No/Yes Once sufficient heat to supply the system has

built up at sensor FZ, the heat source is

prevented from starting. If the system set value is

undercut by 4 K, the heat source is started.

The temperature sensor FZ is in the low loss

header or buffer cylinder.

Maximum shutdown

temperature

30...85...99 °C The burner is switched off once the heating flow

temperature reaches the maximum cut-off

temperature at the latest.

The maximum possible cut-off temperature is

specified by the SAFe of the connected heat

source.

Change the factory setting only in exceptional

cases. The value can only be reduced.

Chapter 11.2, page 32

Maximum boiler output 0...100 % Limiting the performance of the heat source This function is active in heating and DHW

mode.

Cycle deactivation 0...10...60 min Setting the blocking time between switching off

the heat source and switching it back on

This function is active in heating and DHW

mode.

Negative hysteresis -30...-4...0 K Setting that specifies when the set value is

undercut what the difference in temperature

should be before heat production starts

Positive hysteresis 0...2...15 K Setting that specifies when the set value is

exceeded what the difference in temperature

should be before heat production ends

Max. Air Correction -9...0...9 Matching the fan speed The function depends on the heat source.

Min. Air Correction -9...0...9 Matching the fan speed The function depends on the heat source.

Service display None

After hours Maintenance according to hours run

(only in control units with direct activation of

heat source)

• The service display is recorded in the fault

history can be displayed via the building

services management system.

• The status of the service display can be

requested in the fault history.

• The service display can be reset in the Reset

menu.

Next maintenance Setting the number of hours until maintenance is

next due

Burner run time since

last maintenance

Number of hours that have elapsed since

maintenance was last carried out.

Date Service display set according to date: entry of

next maintenance deadline

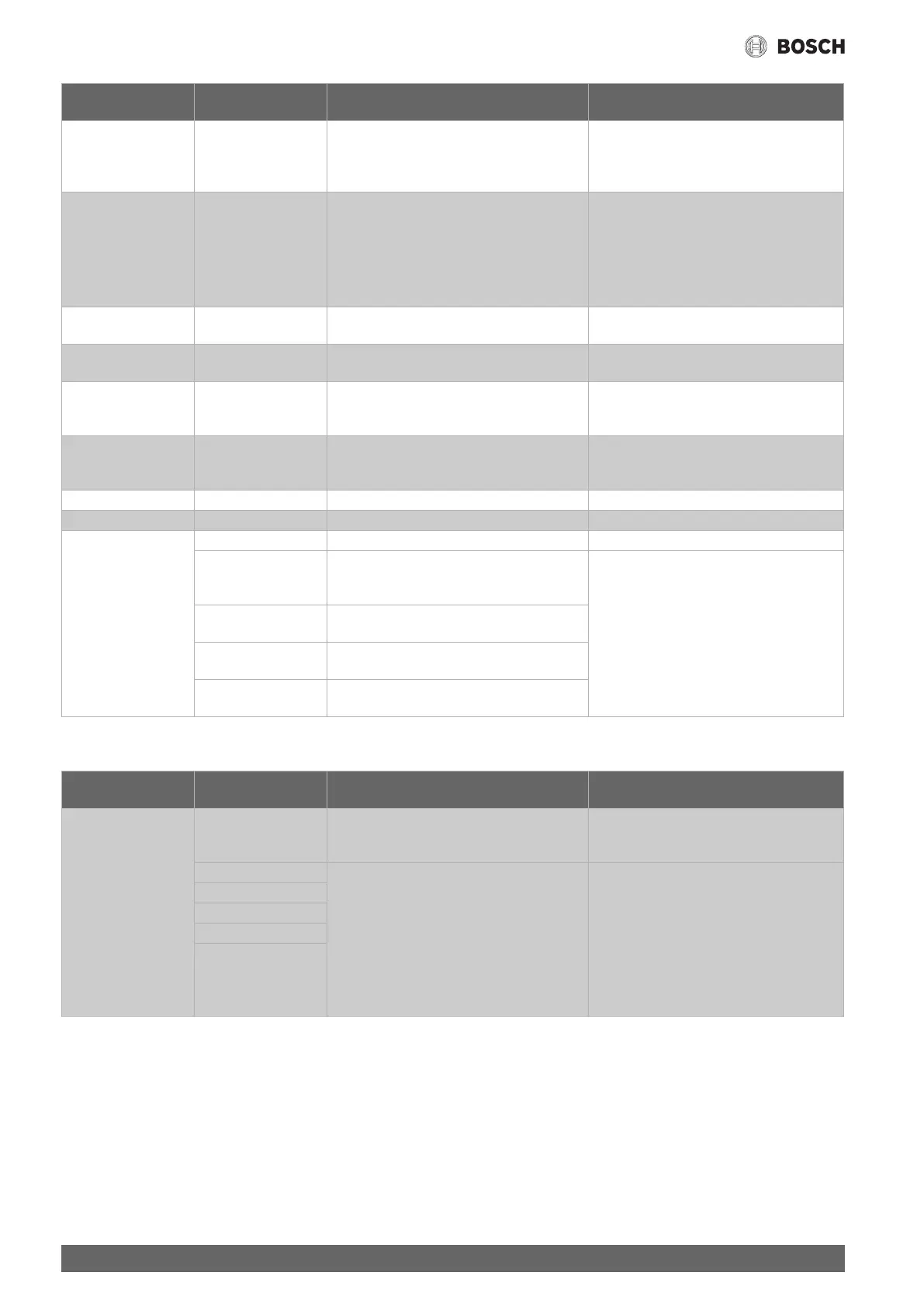

Submenu Settings/adjustment

range

Explanation Note

FM-SI1...FM-SI5 Free/Allocated Inputs for fault displays Only if a FM-SI is installed. Inputs must be

activated ( Chapter 6.7, page 13 and

chapter 11.3, page 32).

Max. pressure 1 Selection of a name for the connected safety

equipment or entry of an individual name

Max-pressure1/2 = maximum pressure

limiter 1 or 2

Min-pr.WMS = minimum pressure limiter

or low water indicator

STB2 Safety = 2nd safety temperature limiter

This must be connected to input SI1 when using

a condensate neutraliser.

Unallocated inputs of the safety chain module

must be jumpered.

Max. pressure 2

Min-PressWMS

Neutralisation

STB 2 safe.

Submenu Settings/adjustment

range

Explanation Note

Loading...

Loading...