Service Manual 04/2010 Rev.B

64

FAILURE IS ELECTRIC OR HYDRAULIC

PRESS THE COIL VALVE CORRESPONDENTS

TO THE DEFECTIVE HYDRAULIC MOVEMENT

(Fig. 93).

IF THE MACHINE WORKS NORMALLY BY

PRESSING THE COIL VALVE, THE PROBLEM

IS DUE TO AN ELECTRIC MALFUNCTION.

Fig.93

TO CONTROL THE CABLE:

Disconnect the machine from power supply.

Open the electric box (5.0).

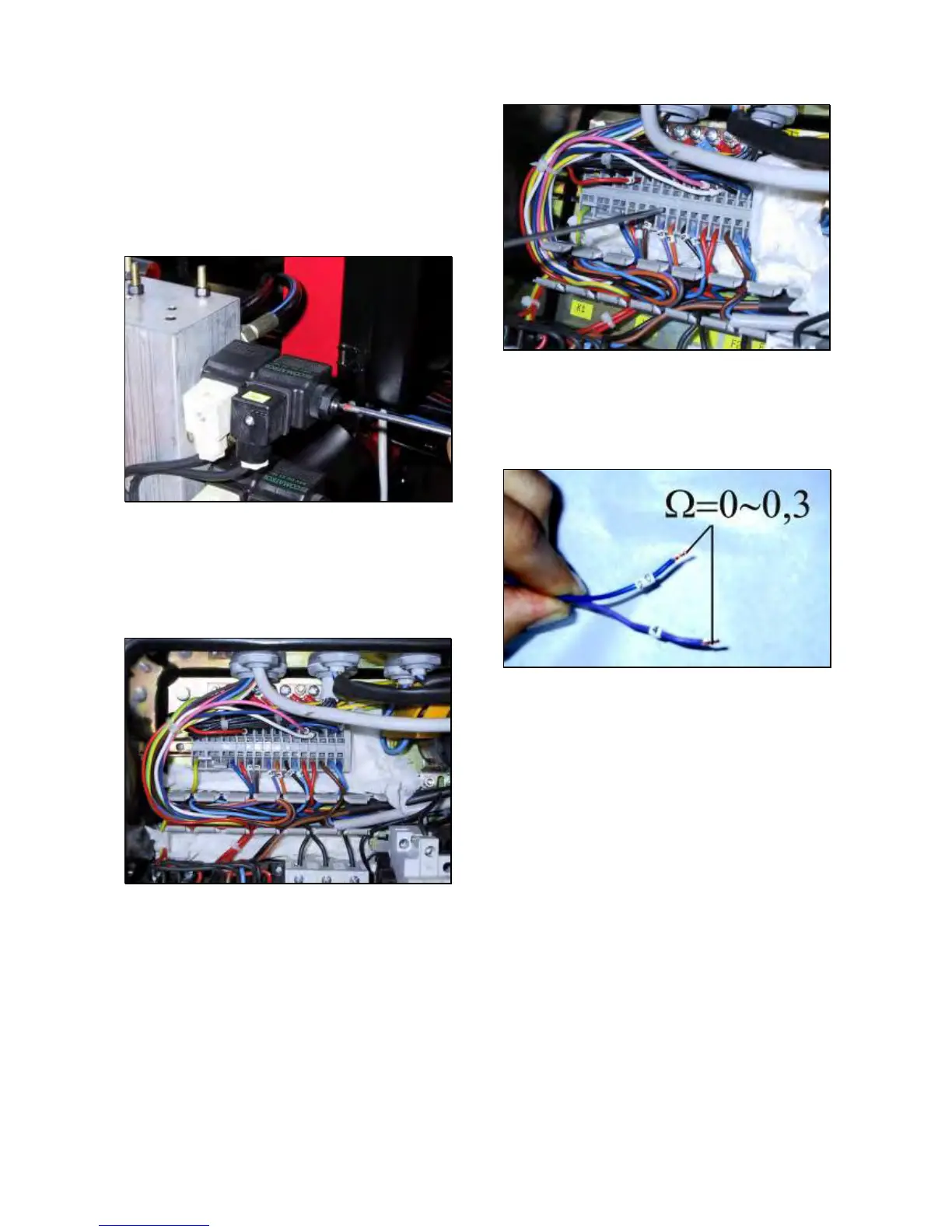

Remove the wires cover (Fig.94).

Fig.94

Remove all portable control wires from

terminals block (Fig.95).

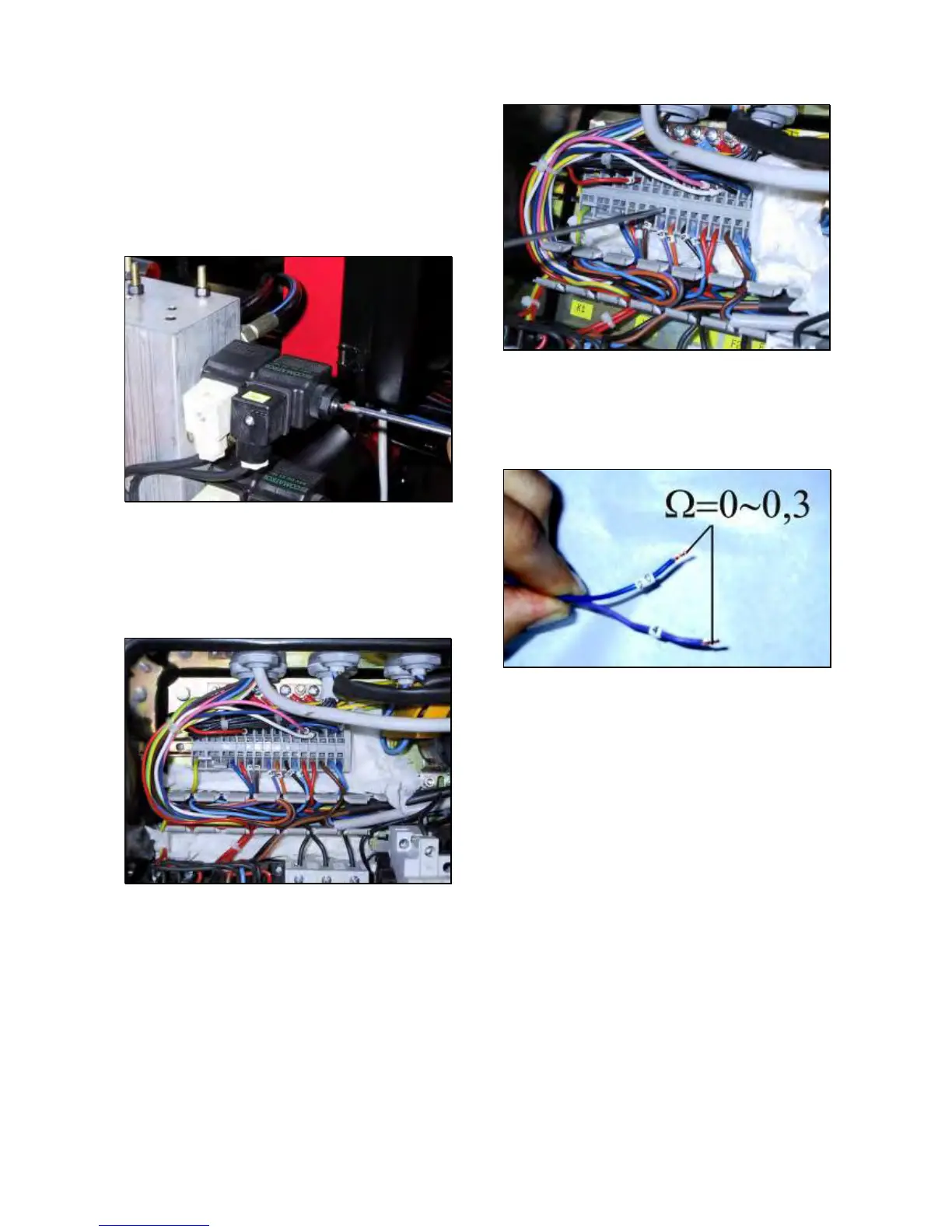

Take a multimeter and select it in Ohm.

Position a multimeter probe on a common end

(the n°1 is for the rotation pedals and the n°20

is for hydraulic commands) and the second

one on the supposed defective wire.

Press the correspondent command on the

portable control and verify if there is continuity

between the two ends (Fig.96)

Fig.95

If there is not continuity remove the suspected

wrong wire from the correspondent micro

switch and verify if there is continuity between

the two ends of the same wire.

Fig.96

TO REPLACE THE CABLE:

Disconnect the machine from power supply.

Open the electric box (5.0).

Remove all remote control wires from

terminals block (Fig.94).

Remove all wires from all micro switches

Remove the defective cable from the portable

control.

Connect by tape the old cable with the new

one to insert the new cable through the inner

cabinet holes.

Release cable strain relief on the electric box.

Take the defective cable away.

Insert the new cable through the strain relief.

Connect all wires FIRMLY to the terminals

block of the electric box, following the

numbers reported on each one .

Tighten the cable strain relief.

Insert 3 steel wires through 8 and 2 position

switches and, only on CE proved machines,

emergency switch seats in order to drive

easily the new wires to the correct direction

inside of the portable control.

Tighten the rotation wire FIRMLY to their

switches in the bottom of the portable control.

Loading...

Loading...