Perfusor® compact, 2.1 gb 5- 1

5

5-Checks after Repair

General

Carry out the respective check blocks depending on the activity

performed. The individual steps are described hereafter in more

detail.

Carry out an overload test if the unit has been dropped (see

“Overload Check” ➨ p. 3 - 17).

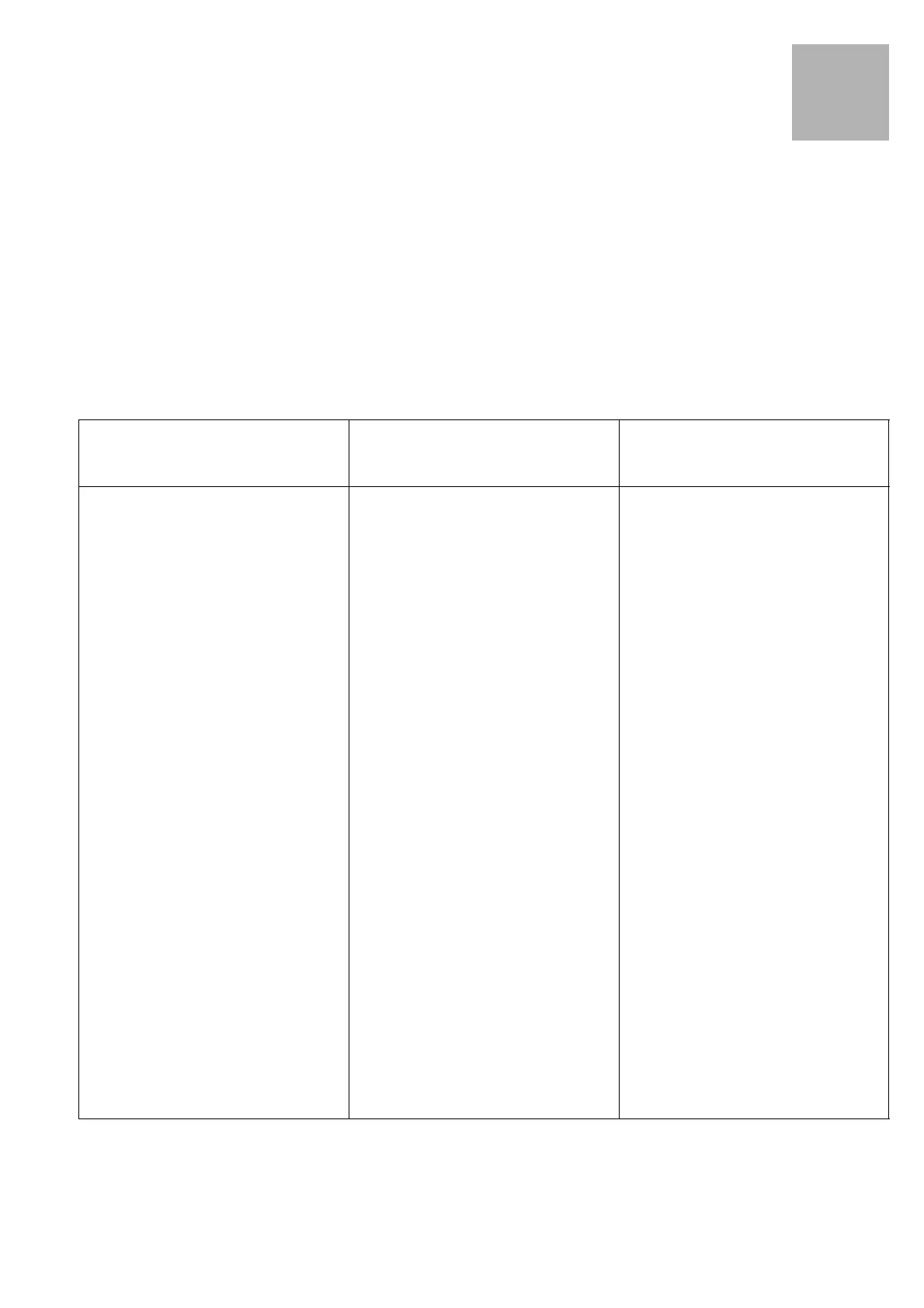

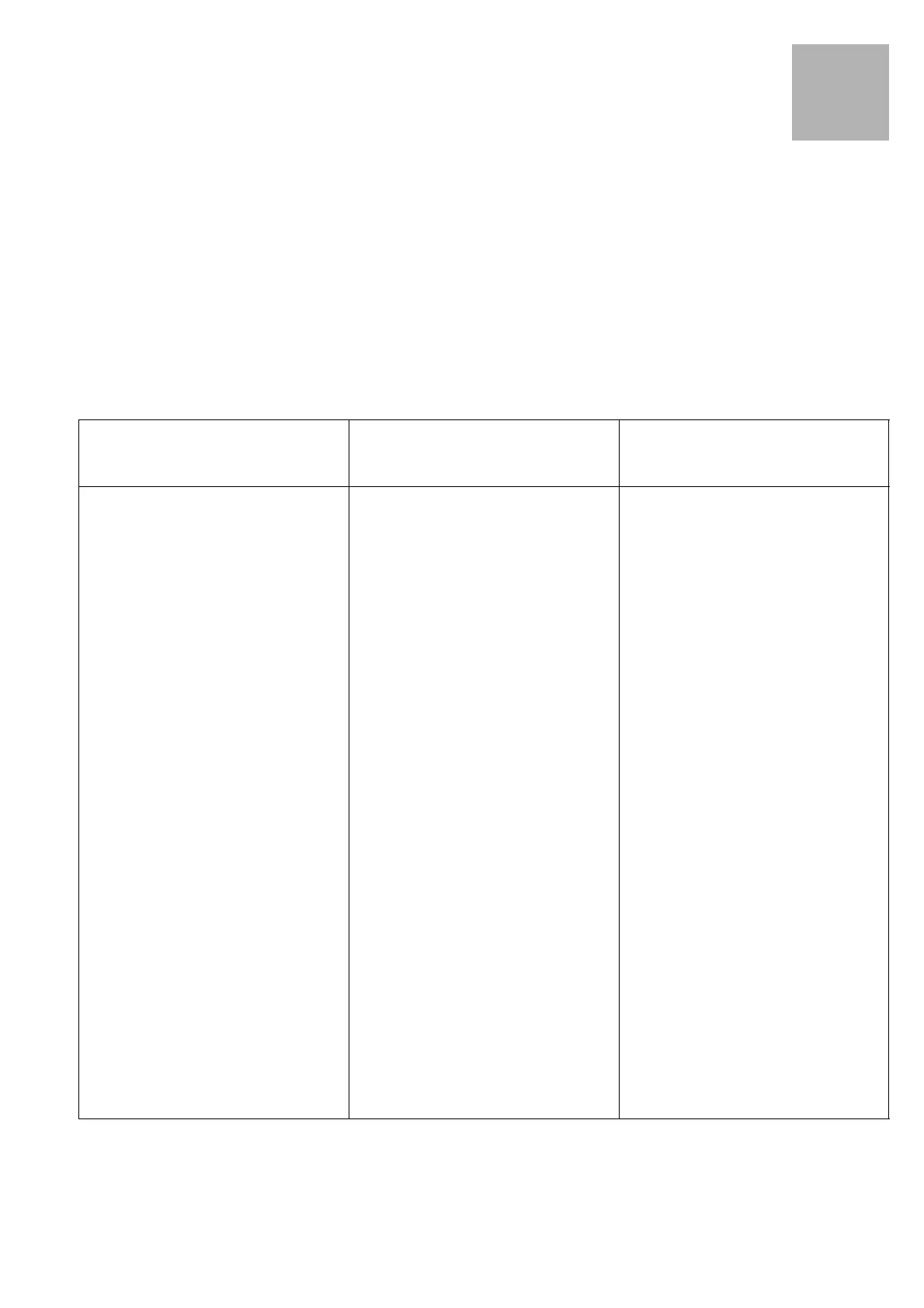

Check List for Checks after Repair

Visual Inspection Electrical Safety

according to IEC/EN 60601-1

or VDE 0750 and VDE 0751

Functional Inspection

❒ Cleanliness

❒ Completeness

❒ Damage and faults affecting safety

❒ Damage to and readability of the label

❒ Syringe holder, axial positioner, drive

head

❒ Syringe table, quick reference guide

❒ Membrane keyboard

❒ Battery compartment cover, battery

compartment and -contacts

❒ Unit feet

❒ MFC connector

❒ Holder for pole fixation, side snap-in

mechanism

❒ Mains power lead

❒ Line voltage

acc. to TSC ______ V

❒ Protective Conductor Resistance

acc. to TSC ______ Ω

❒ Patient leakage current

acc. to TSC _____ µA

Mechanical Inspection

❒ Holder for pole fixation

❒ Stacking function

❒ Syringe holder

❒ Drive head lock

Switch on unit.

❒ LC display

❒ Self-test

❒ Audible alarm

Operation

❒ Infusion

❒ Staff call

❒ Bolus

Pressure cut-off

with calibration gauge

❒ Pressure stage 1 (15 - 35 N)______ N

❒ Pressure stage 2 (30 - 55 N)______ N

❒ Pressure stage 3 (45 - 70 N)______ N

❒ Bolus (45 - 70 N) _________ N

Syringe recognition

❒ 20 ml

❒ 50 ml

Pre- and end alarm

❒ Pre-alarm

❒ End alarm

5 - 6

2.1

Loading...

Loading...