MAINTENANCE PROCEDURES

Spark Plugs

Spark plugs inspection or replacement

may be performed by an authorized

Lynx dealer, repair shop, or person of

your own choosing. Spark plugs in-

spection or replacement requires an

in-depth technical knowledge. Though

not required, it is recommended that

an authorized Lynx dealer performs

spark plugs inspection or replacement.

Engine Stopper (E-TEC

models)

Engine Stopper Adjustment

The engine stopper is located on the

LH front engine support, in front of the

drive pulley.

1. Remove tether cord cap from en-

gine cut-off switch.

2. Remove the LH lower side panel, re-

fer to

CONTROLS, INSTRUM ENTS

AND EQUIPMENT

.

3. Remove drive belt guard, refer to

DRIVE BELT GUARD REM OVAL

.

4. Loosen the three screws retaining

the engine stopper to the engine

support just enough to allow a verti-

cal play (1/2 to one turn).

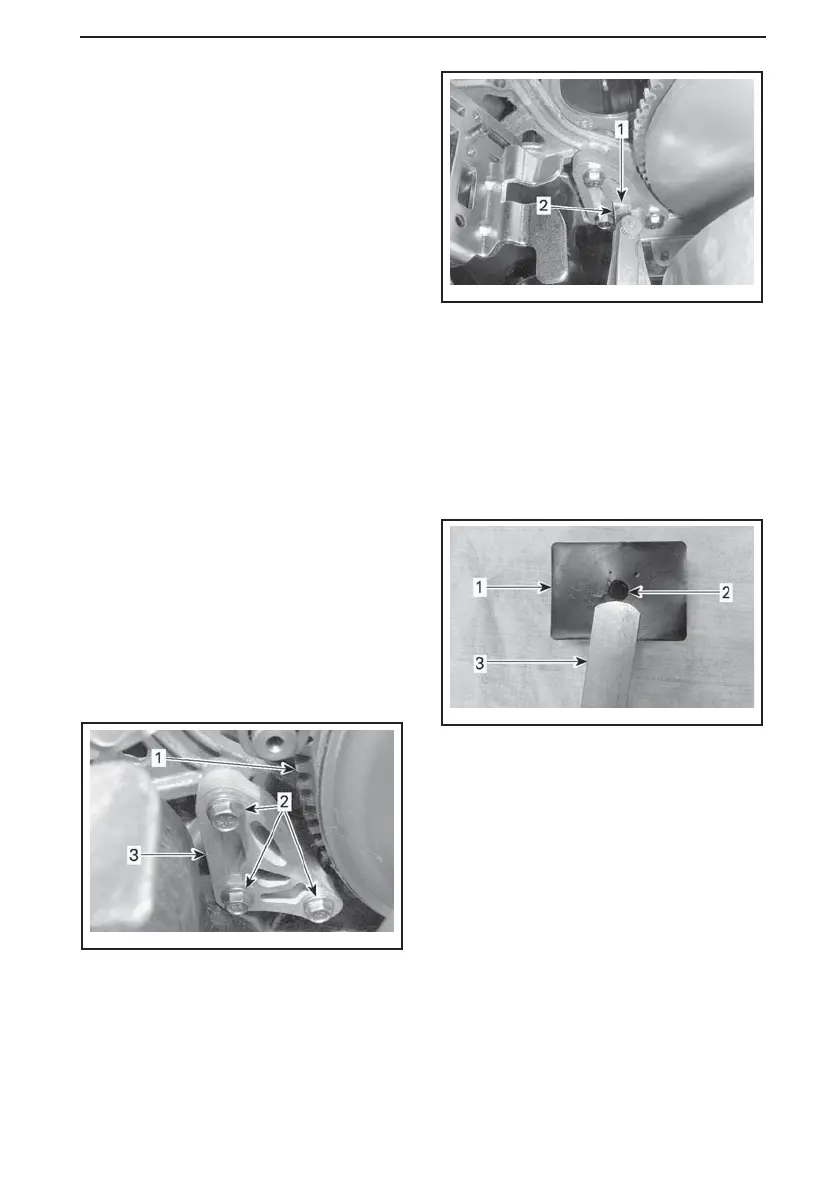

mmo2010-009-007_a

1. Drive pulley

2. Engine stopper screws

3. Engine stopper

5. Insert a 0.5 mm (.02 in) feeler gauge

in the engine stopper opening (see

illustration).

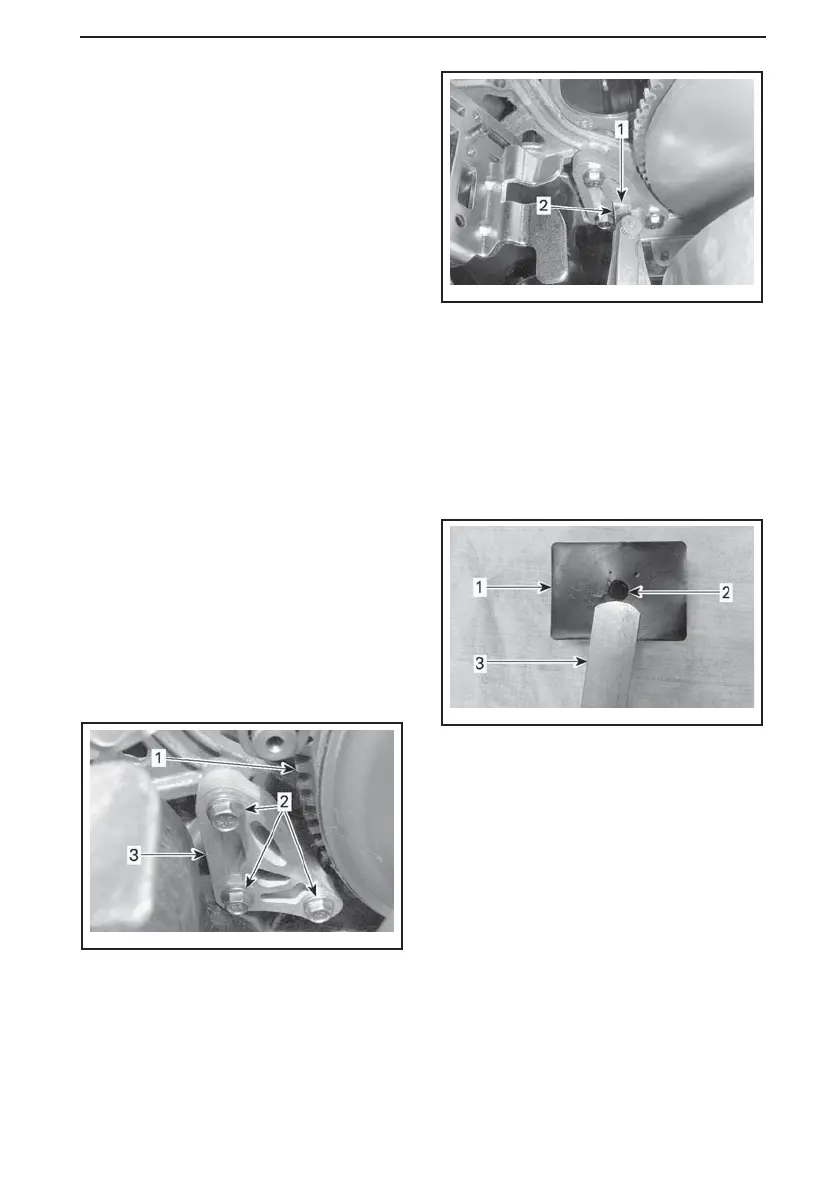

mmo2010-009-001_a

1. Opening

2. Feeler gauge

6. Place feeler gauge between engine

stopper and rubber stop block (on

engine).

NOTE: Do not insert the feeler gauge

too deep, as it will pass over the bump

at the surface of the rubber stop block

and alter adjustment. See illustra tion.

mmo2010-009-002_a

1. Rubber stop block

2. Bump

3. Feeler gauge

7. Tighten screws to specification, fol-

lowing the illustrated s equence.

Take care not to pinch the feeler

gauge.

______________

109

Loading...

Loading...