MAINTENANCE PROCEDURES

mmo2011-003-011_a

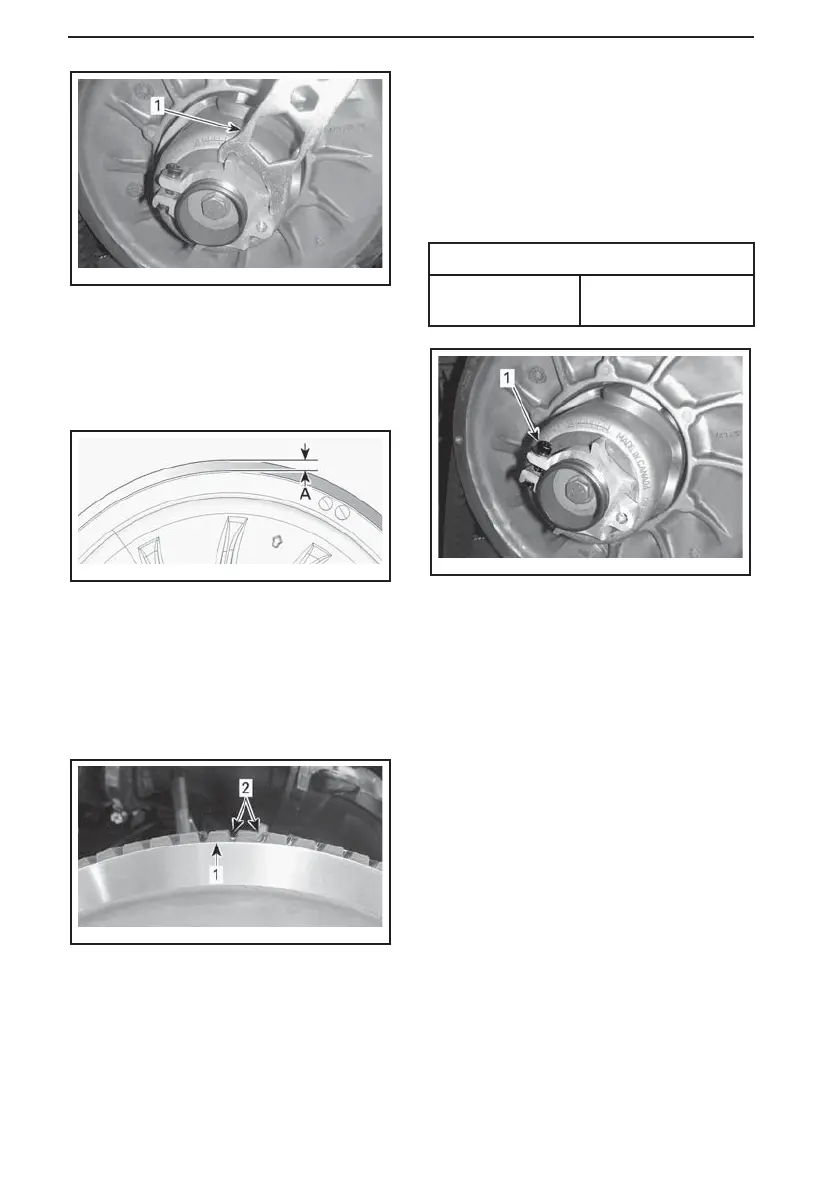

ADJUSTER HUB

1. Suspension adjustment tool

NOTE: The adjustment ring has left

hand treads.

Belt without External Cogs

mmr2009-081-001_a

PRELIMINARY SETTING

A. 0 mm to 2 mm (0 in to .08 in)

Repeat step 5 until the bottom of

grooves on the external side of drive

belt are flush with the driven pulley

edges.

mmr2008-040-108_a

PRELIMINARY SETTING

1. Driven pulley edge

2. External drive belt grooves

NOTE: Turning the ring counterclock-

wise low ers the belt in the pulley. Turn-

ing the ring clockwise raises the belt in

the pulley.

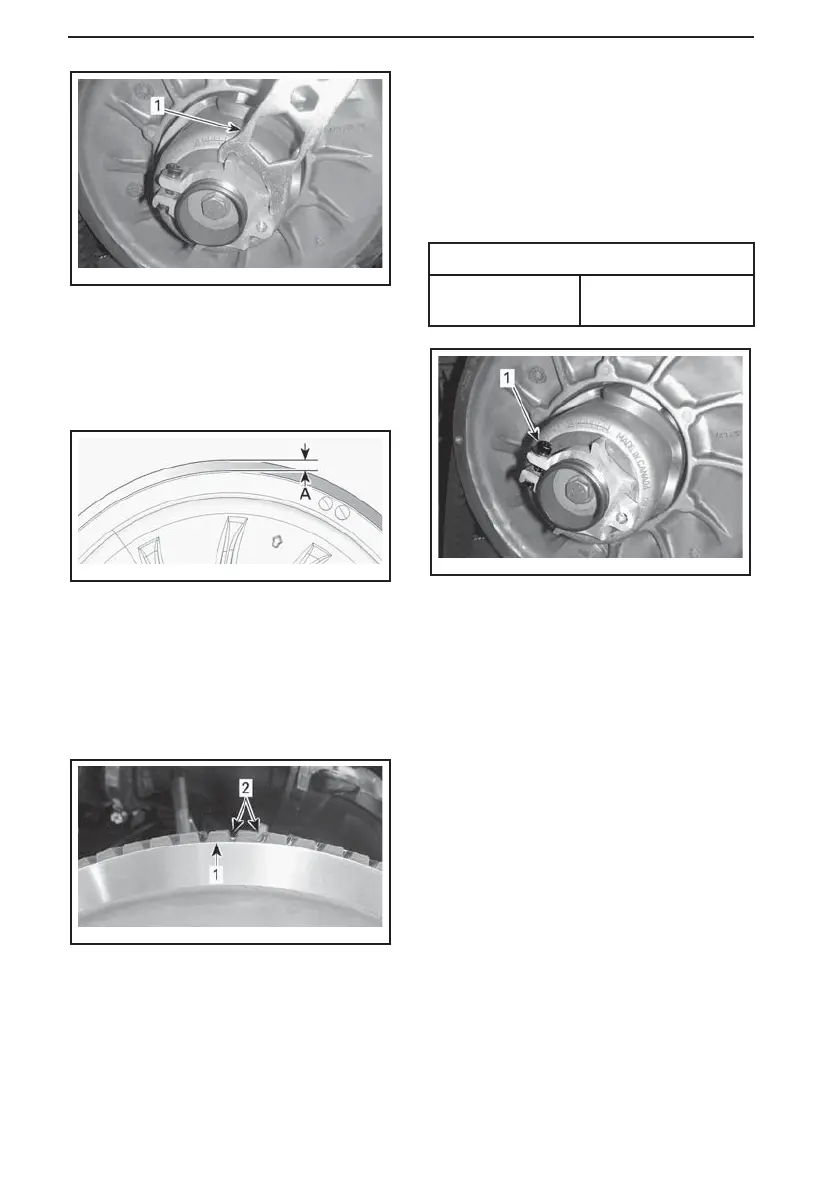

6. Tighten the clamping bolt to specifi-

cation.

TIGHTENING TORQUE

Clamping bolt

5.5 N•m ± 0.5 N•m

(49 lbf•in ±4lbf•in)

mmo2011-003-010_b

1. Clamping bolt

7. Install belt guard, refer to

DRIVE

BELT GUARD INSTALLATION

.

8. Close side panel, refer to

SIDE

PANELS

in

CONTROLS, INSTRU-

MENTS AND EQUIPMENT

.

NOTE: This setting is correct as a pre-

liminary adjustment for most models

and belt types. In some cases, when

starting the engine, the vehicle could

creep, indicating that the belt is too

tight.

If the vehicle creeps, lower the drive

belt height from the preliminary set-

ting. Repeat procedure until creeping

stops.

Reverse Activation

NOTE: The reverse may not activate

or may be harder to activate if the belt

is positioned too high in the driven pul-

ley. If reverse activation doe s not work

properly, ensure the drive belt is prop-

erly adjusted. Adjust the drive belt

lower in the driven pulley if needed.

114

______________

Loading...

Loading...