Measuring Ampifier Type 2525

User Manual Vol.1

6–3

BE1406–12

Chapter 6 –Making a Measurement

Instructions for Measurement

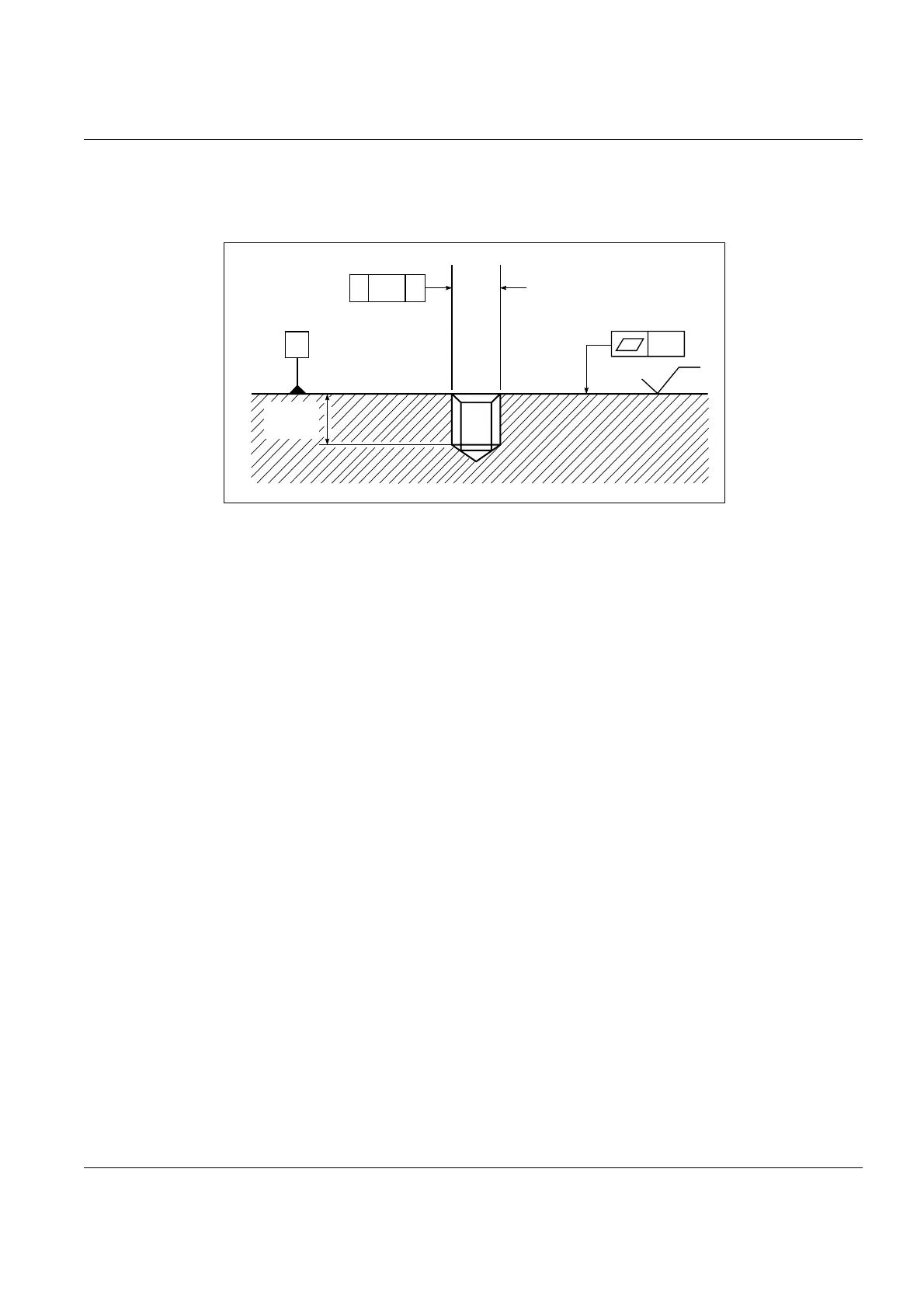

2. If you are using an accelerometer stud, the hole must be tapped according to the

standard shown in Fig.6.1.

3. Choose a location which provides a short and rigid vibration transmission path

to the vibration source. This avoids any compliance and damping elements

present in the structure like gaskets. For example, when measuring vibrations

on rotating machinery, bearing housings are often good places to mount the

accelerometer.

In many cases the accelerometer mounting location is fairly obvious and will be

dictated by your application. In any case, the accelerometer should be mounted

with its main sensitivity axis aligned with the desired measurement direction.

The accelerometer responds to vibrations in directions other than the main sen-

sitivity axis. The red dot on Brüel&Kjær accelerometers can be aligned with the

direction of maximum transverse vibration to minimize their affects.

4. Mount the accelerometer (see section 3.1.5 for grounding).

6.4 Instructions for Measurement

6.4.1 Basic Measurement

1. Place the amplifier on a flat surface. You may want to flip out the feet on the

bottom of the amplifier so that the screen is easier to see.

2. Connect the three-prong mains cable to the contact on the back panel of the

amplifier, and plug into a grounded socket.

Fig.6.1 Recommended tolerances for the mounting surface and

tapped fixing hole. Dimensions and symbols in accordance

with ISO 1101

841363/1e

A

A⊥ ø 0.02

10 - 32 UNF

M3, M4, M5

or M8

0.01

1.6

0.25

Absolute

Min. Depth.

4 mm

Loading...

Loading...