GB

MXV, MXV-B Rev4 - Operating Instructions Page 21 / 136

8.2. Dismantling the system

Close the suction and delivery gate valves and drain

the pump casing before dismantling the pump.

8.3. Dismantling the pump

OFF

Before dismantling, close the gate valves in the suction

and delivery pipes and empty the pump casing (g. 4).

For dismantling and re-assembly refer to the section

drawing (section 14.) and gures 5, 6.

Dismantling and inspection of all internal parts can be

carried out without removing the pump casing (14.00)

from the pipeline.

Sequence for dismantling MXV-B:

By removing the nuts (61.04) from the tiebolts (61.02)

the motor can be taken out complete (99.00), with all

internal parts of the pump without removing the pump

casing (external jacket 14.02) from the pipeline.

Sequence for dismantling MXV(L), MXV(L)4:

1. Mark the position of the motor on the lantern bracket

(32.00), and the position of the lantern bracket on

the upper cover (34.02), ... on the external jacket

(14.02), ... on the pump casing (14.00).

2. Remove the screw (32.32) with the washer (32.31)

and the coupling guard (32.30).

3. Loosen the screws (64.25) of the coupling (64.22).

ATTENTION: to avoid compressing the spring of the

mechanical seal (36.00) because of axial shifting

of the shaft (64.00), we recommend to loosen the

screws (64.25) of the coupling (64.22) even only for

removing or replacing the motor.

Afterward reposition the shaft (64.00) as indicated in

section 9.2.

4. Disconnect the power cable from the terminal box,

remove the screws (70.18) with the nuts (70.19) and

remove the motor away from the coupling (64.22)

(g.5a).

For MXV(L) 25-32-40, MXV(L)4 25-32-40:

5. Remove the nuts (61.04) from the tiebolts (61.02).

6. Remove the lantern bracket (32.00), complete with

bearing (66.00) and coupling (64.22) from the shaft

(64.00) and from the external jacket (14.02).

Once the lantern bracket (32.00) has been removed,

all the internal parts can be extracted with the shaft

(64.00) from the external jacket (14.02).

7. Remove the upper cover (34.02) with the o-ring

(14.20) and then the delivery casing (20.00).

For MXV(L) 50-65-80, MXV(L)4 50-65-80:

5. Remove the screws (61.07) and remove the lantern

bracket (32.00), complete with bearing (66.00) and

coupling (64.22) from the upper cover (34.02) and

from the shaft (64.00) (g.5a).

6. Remove the nuts (61.04) and washers (61.03) from

the tiebolts (61.02).

7. Remove the upper cover (34.02) from the shaft

(64.00) and from the external jacket (14.02) - or with

the external jacket from the pump casing (14.00) -

with the aid of a mallet or lever, exercising pressure

in alternate operations, from diametrically opposite

positions.

Once the upper cover (34.02) has been removed,

all the internal parts can be extracted from the pump

casing (14.00).

8.4. Replacing the mechanical seal

Make sure the spring of the new mechanical seal is

set with the direction of the winding suitable for the

direction of rotation of the shaft.

Make sure that all parts with which the mechanical seal

comes into contact are perfectly clean and free from

any burr or cutting edges.

The seal rings in EPDM (Ethylene-Propylene) must

never come into contact with oil or grease. To

facilitate the mounting of the mechanical seal, lubricate

the shaft, the seating of the stationary part and the seal

rings with clean water or any other lubricant compatible

with the material in which the seal rings are made.

Use every precaution so as not to damage the seal

surfaces with blows or angular impact.

Only for MXV(L)(4) 25,32,40,50,65,80

Remove the mechanical seal (36.00), the rotating

part from the shaft (64.00), making sure the shaft is

not scratched, and then the xed part from the upper

cover (34.02).

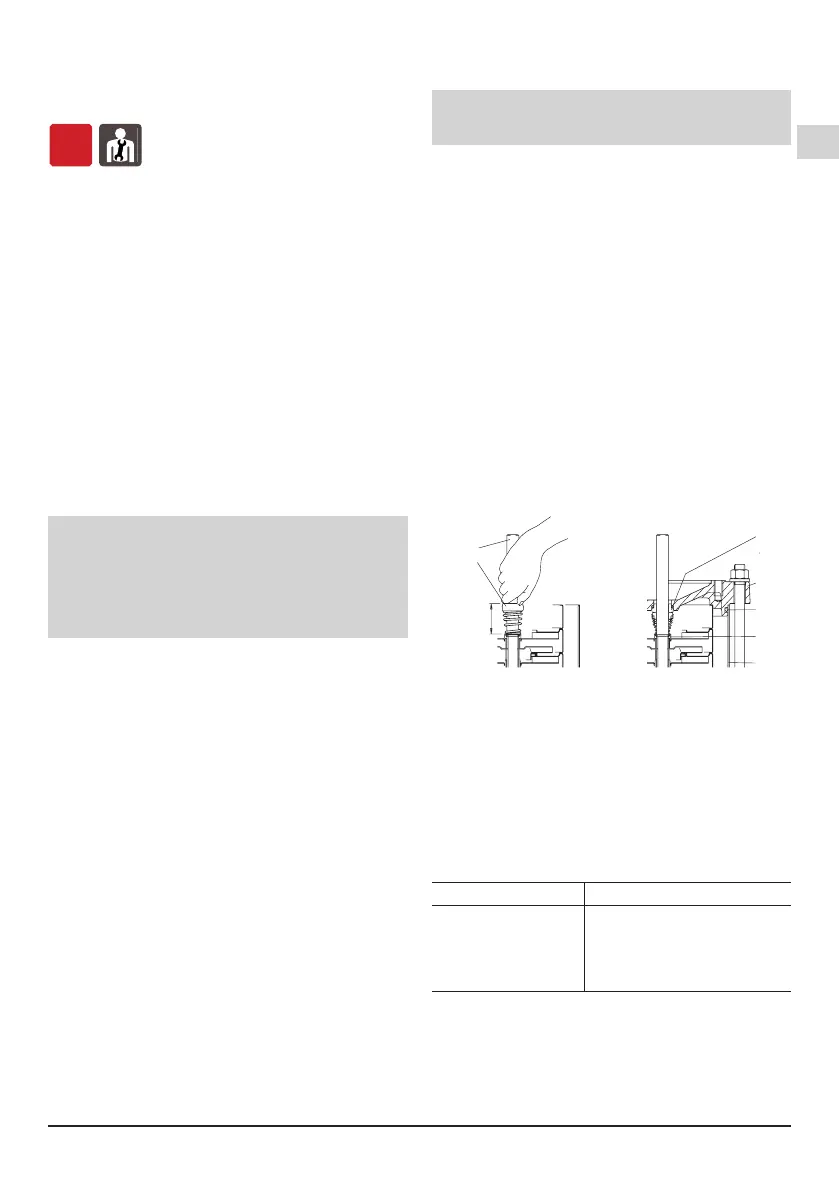

Push the rotating part as far as the shoulder ring

(36.52) on the shaft (64.00), without compressing the

spring. Check the length before and after insertion and

raise the rotating ring as far as the initial length (L1 in

g.5).

In this way, correct compression of the spring will be

ensured when the xed part is mounted and after the

shaft is locked in the coupling (L2 in g.6b).

64.00

36.00

Parte

14.20

14.02

36.52

34.02

(*)

64.22

64.25

Fig.5 Montaggio tenuta meccanica

Fig. 6b

Rotore sollevato,

posizione di

bloccaggio

albero nel giunto

sollevamento albero

nel giunto. (*) Spina per

albero non bloccato

Rotore appoggiato

Fig. 6a

L1

L2

rotante

fissa

Parte

36.00

64.00

4.93.226/2

4.93.226/1

Fig.5 Inserting the mechanical seal

Only for MXV(L) 100, MXV(L)4 100 (see section 16.

page. 131)

8.5. Replacing the ball bearing MXV(L), MXV(L)4

If the ball bearing (66.00) has to be replaced, use a

2RS1 C3-type, of the size marked on the ball bearing

to be replaced and containing grease lubricant suitable

for the operating temperature.

The size of the bearing depends on the size of the

motor:

motor size ball bearing

80 6206, 2RS1, C3

90 6207, 2RS1, C3

100-112 6208, 2RS1, C3

132 6310, 2RS1, C3

160-180 6313, 2RS1, C3

8.6.

First-stage bearing and intermediate bearing

The MXV 50-16, 65-32 and 80-48 pumps have a

bearing sleeve (64.10) on the shaft (64.00) and a

bearing in the stage casing (25.03) behind the rst

impeller (according to the order of suction).

Starting with the MXV.. 25-212, MXV.. 32-412 e MXV..

40-811, MXV 50-1611, MXV 65-3208 and MXV 80-

Rotating

part

Fixed

part

Loading...

Loading...