Instruction Manual, November 2016 Page 27

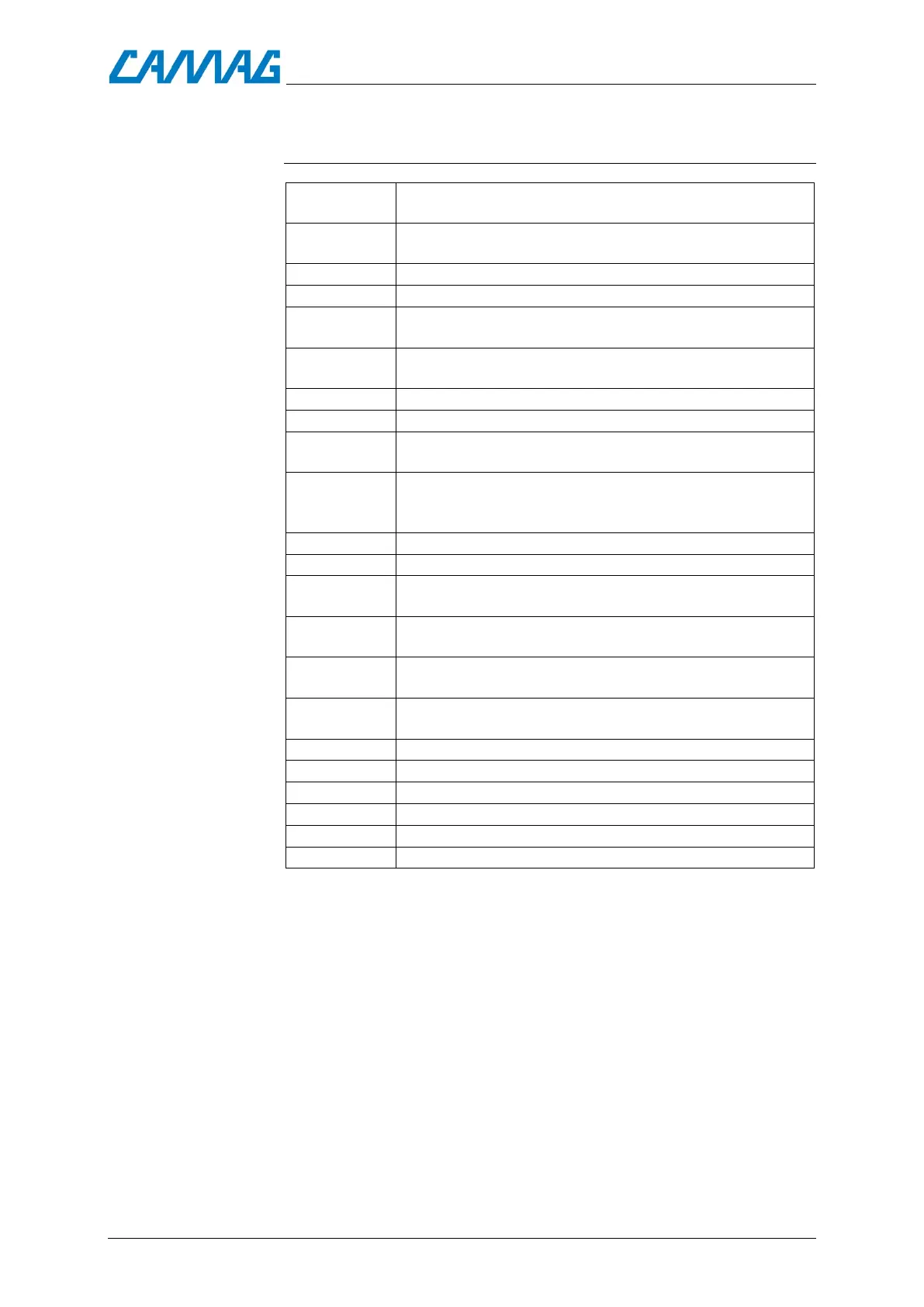

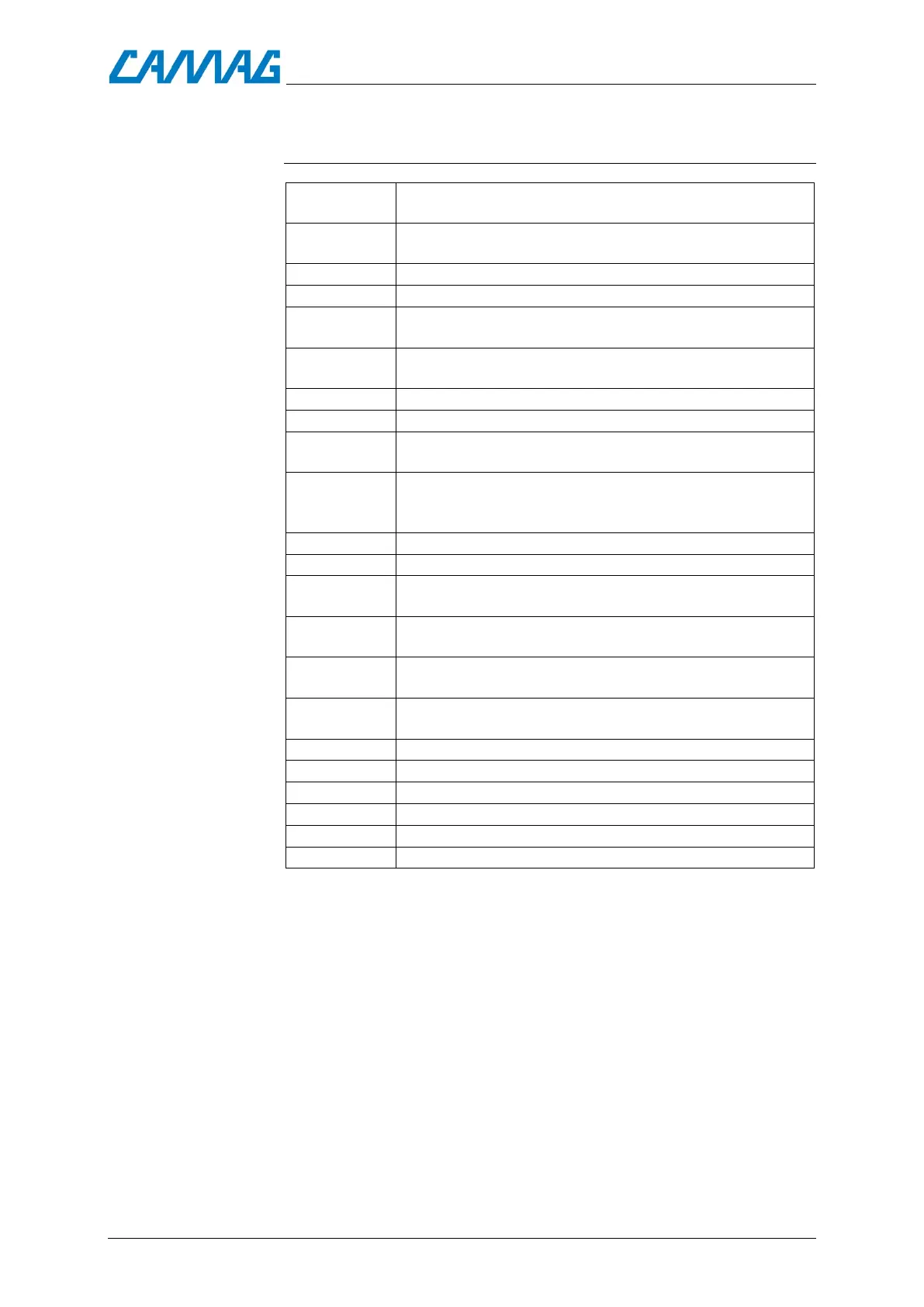

6.8. Error messages

Error # Description

30 There is no glass chamber or the chamber is not in the

The lever is in the up position.

The drying compartment door is open.

33 The position of the humidity module valve was not de-

34 The changing of positions of the humidity module valve

was lasting too long, i.e. valve is locked or dirty.

There is no solvent (mobile phase) in the chamber.

There is no TLC plate in the ADC2.

37 Humidity / temperature sensor damaged, bad connec-

38 Migration front is moving backwards. There is too little

solvent available or there are temperature problems,

Tolerances of TLC plate or TT-Chamber too big.

The TT-Chamber has been moved during development.

The drying compartment lid has been opened during

development.

42 The lever has been moved to the up position during de-

45 The humidity module is disconnected or there is no

47 The edge of the plate holder could not be detected

while lowering the plate into the TT-Chamber.

Interruption of chromatography by mains power failure

Spindle drive (drying comp.): ref-switch (LSX) active

Lift drive (plate lift): ref-switch (LSX) active

Spindle drive (drying comp.): ref-switch was expected

Lift drive (plate lift): ref-switch was expected:

Internal device voltage 24V too low

Loading...

Loading...