Refrigerant piping

Connection

Step 2: Remove burrs

Burrs can affect the air-tight seal of

refrigerant piping connection. They must be

completely removed.

1. Hold the pipe at a downward angle to

prevent burrs from falling into the pipe.

2. Using a reamer or deburring tool,

remove all burrs from the cut section of

the pipe.

Pipe

Reamer

Point down

Step 3: Flare pipe ends

Proper aring is essential to achieve an

airtight seal.

1. After removing burrs from cut pipe,

seal the ends with PVC tape to prevent

foreign materials from entering the pipe.

2. Sheath the pipe with insulating material.

3. Place are nuts on both ends of pipe.

Make sure they are facing in the right

direction, because you can’t put them on

or change their direction after aring.

Flare nut

Copper pipe

4. Remove PVC tape from ends of pipe

when ready to perform aring work.

5. Clamp are form on the end of the pipe.

The end of the pipe must extend beyond

the edge of the are form in accordance

with the dimensions shown in the table

below.

PIPING EXTENSION BEYOND FLARE

FORM

Outer Diameter

of Pipe (mm)

A (mm)

Min. Max.

ø6.35 (ø0.25”) 0.7 (0.0275”)

1.3 (0.05”)

ø9.52 (ø0.375”) 1.0 (0.04”) 1.6 (0.063”)

ø12.7 (ø0.5”) 1.0 (0.04”) 1.8 (0.07”)

ø16 (ø0.63”) 2.0 (0.078”) 2.2 (0.086”)

ø19 (ø0.75”) 2.0 (0.078”) 2.4 (0.094”)

A

Flare form

Pipe

6. Place aring tool onto the form.

7. Turn the handle of the aring tool

clockwise until the pipe is fully ared.

8. Remove the aring tool and are form,

then inspect the end of the pipe for

cracks and even aring.

Step 4: Connect pipes

When connecting refrigerant pipes, be

careful not to use excessive torque or to

deform the piping in any way. You should

rst connect the low-pressure pipe, then the

high-pressure pipe.

MINIMUM BEND RADIUS

When bending connective refrigerant piping,

the minimum bending radius is 10cm.

Radius

≥10cm (4in)

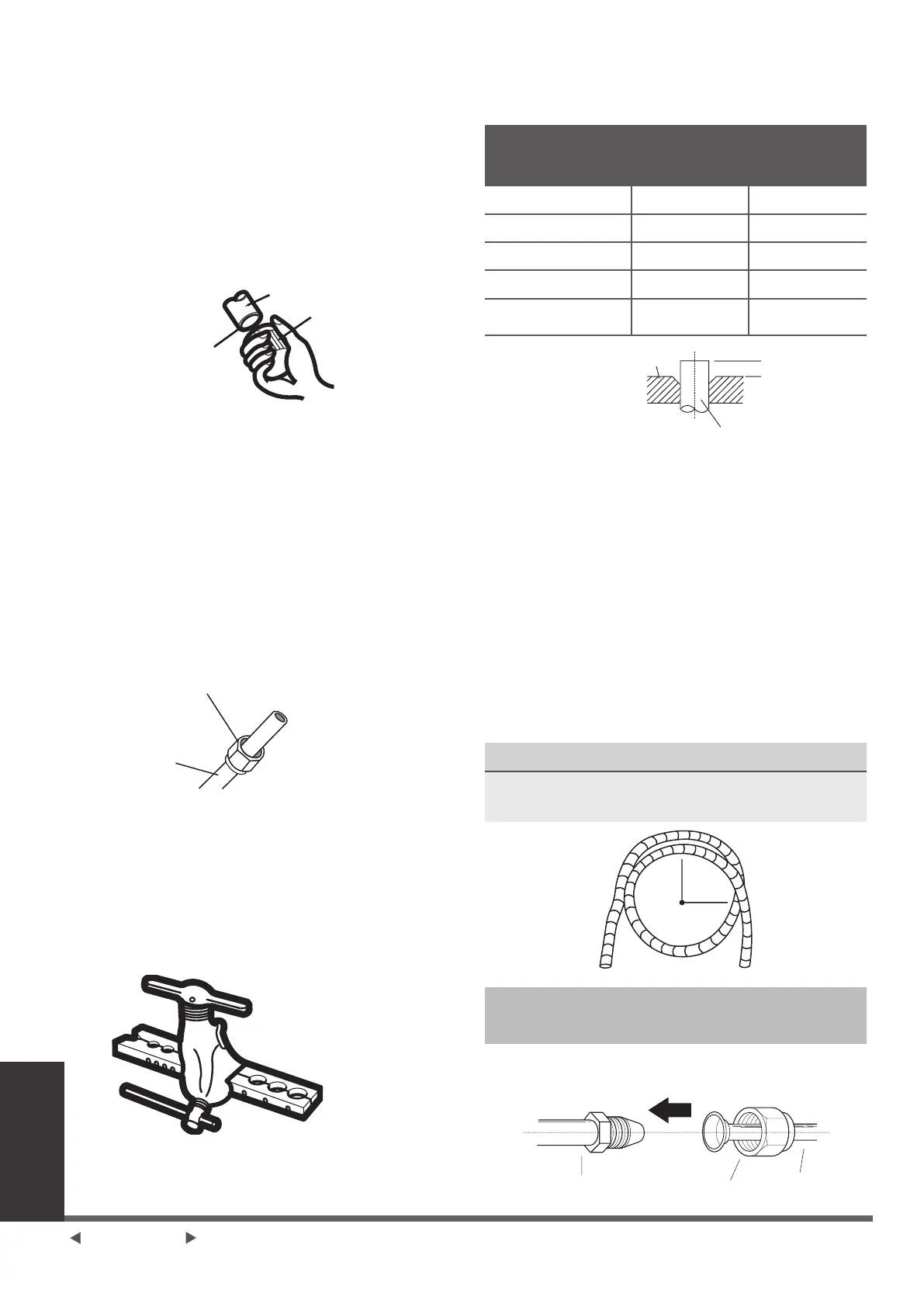

Instructions for Connecting Piping to

Indoor Unit

1. Align the center of the two pipes that you

will connect.

Indoor unit tubing Flare nut Pipe

Page 16-GB

Loading...

Loading...