Page 17 of 45

9.3 Brushes and screens

The rotating brushes distribute the liquid evenly and brush away the superfluous liquid/paint.

The brushes are similar and made from durable nylon. The brushes are easy to mount and dismount for

cleaning. The setting of the brushes depends on the treatment and profile of the item.

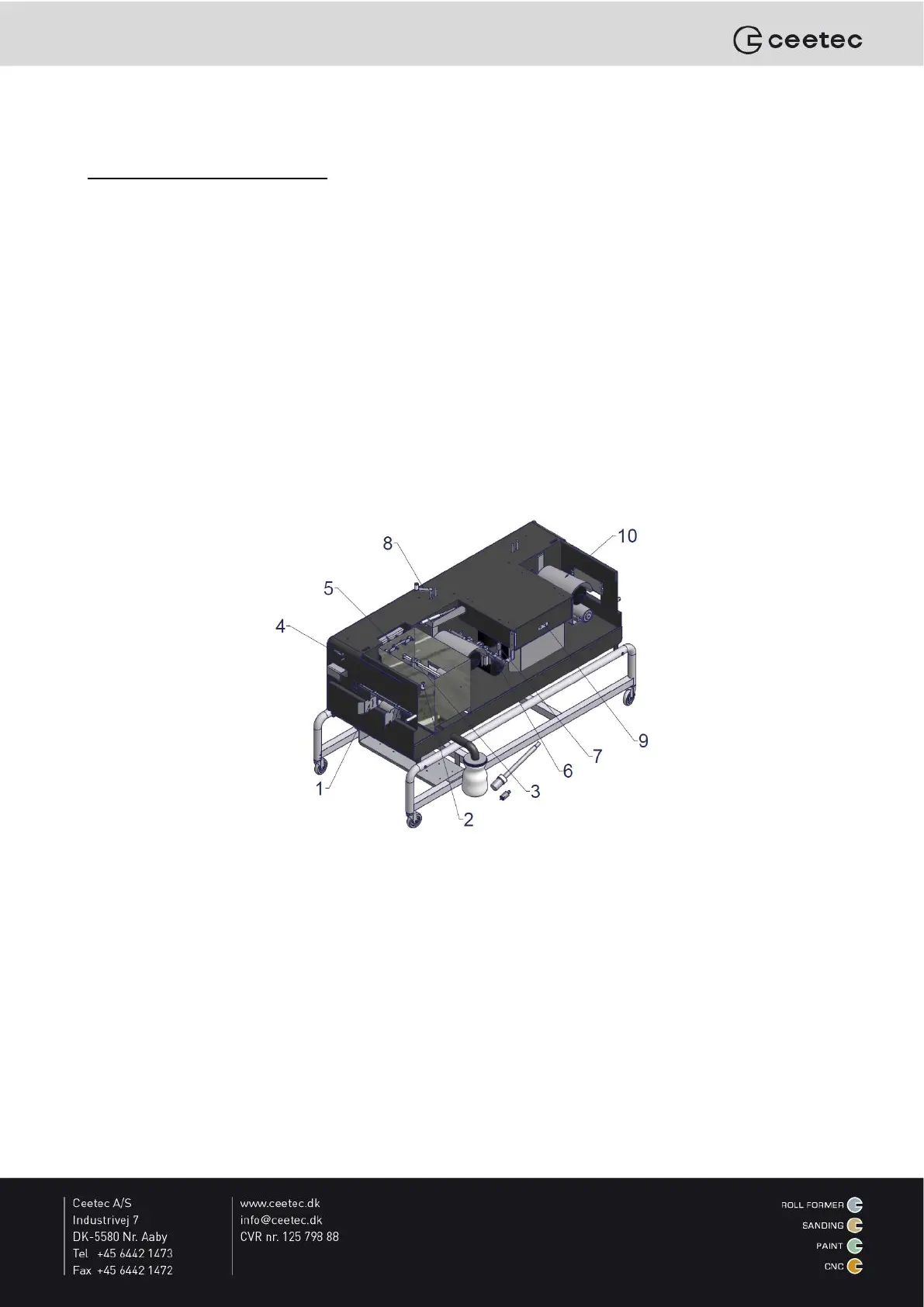

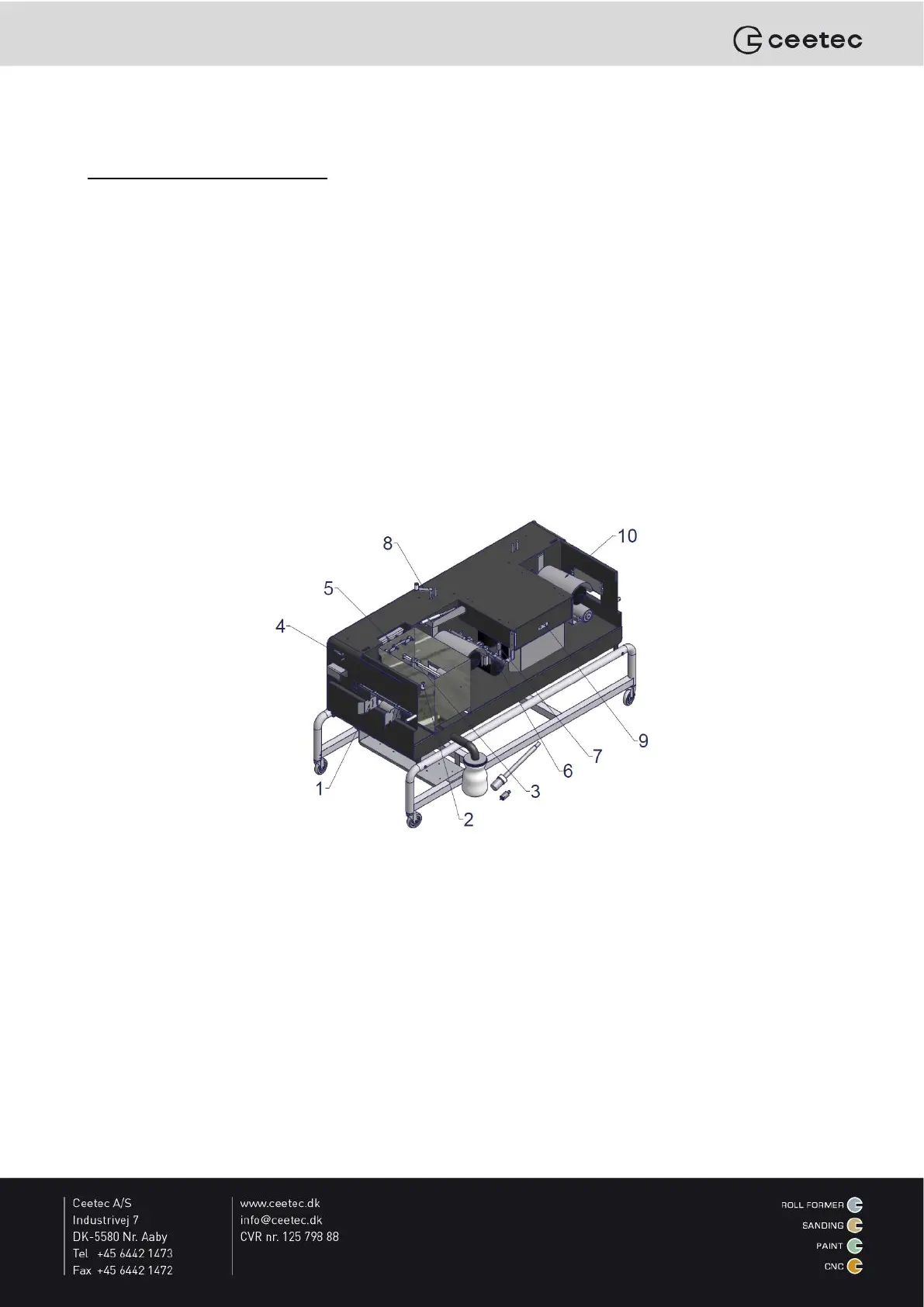

The setting of the brush pressure on the horizontal brushes is carried out by turning the four spindles (8) with

the handle.

e. When turned clockwise: the brush is raised (respectively less pressure on the top and more

pressure on the bottom brushes).

a. When turned counter-clockwise: the brush is lowered (respectively more pressure on the top

brushes and less pressure on the bottom brushes).

The setting of the brush pressure on the vertical brushes is carried out by tuning the two spindles (9). Use

the same handle as for the horizontal brushes.

f. When turned clockwise: The brush is moved away from the operator (respectively more

pressure on the left brushes and less pressure on the right brushes).

b. When turned counter-clockwise: The brush is moved towards (respectively less pressure on

the left brushes and more pressure on the right brushes).

The screens (10) prevent spray from the brushes and drips on the treated surface, and so they must always

be mounted before the machine is started. The screens are set so there is app. 10 mm “air” between the

item and the front edge.

Loading...

Loading...