Page 21 of 45

11 Maintenance

For any service and maintenance task it must be ensured that the machine is:

- Free of items (empty)

- Not moving (emergency stop is activated)

- Power supply is disconnected

Never try to touch parts of the machine during operation

11.1 Regular maintenance

In general the machine must be checked and lubricated at least 12 times a year or after approximately 100

operating hours.

Some of the machine’s moving parts are equipped with external lubricating nipples which make the regular

maintenance easier for the operator.

11.2 Bearings

The bearings must be checked and replaced in case of defect. The bearings are lubricated as follows:

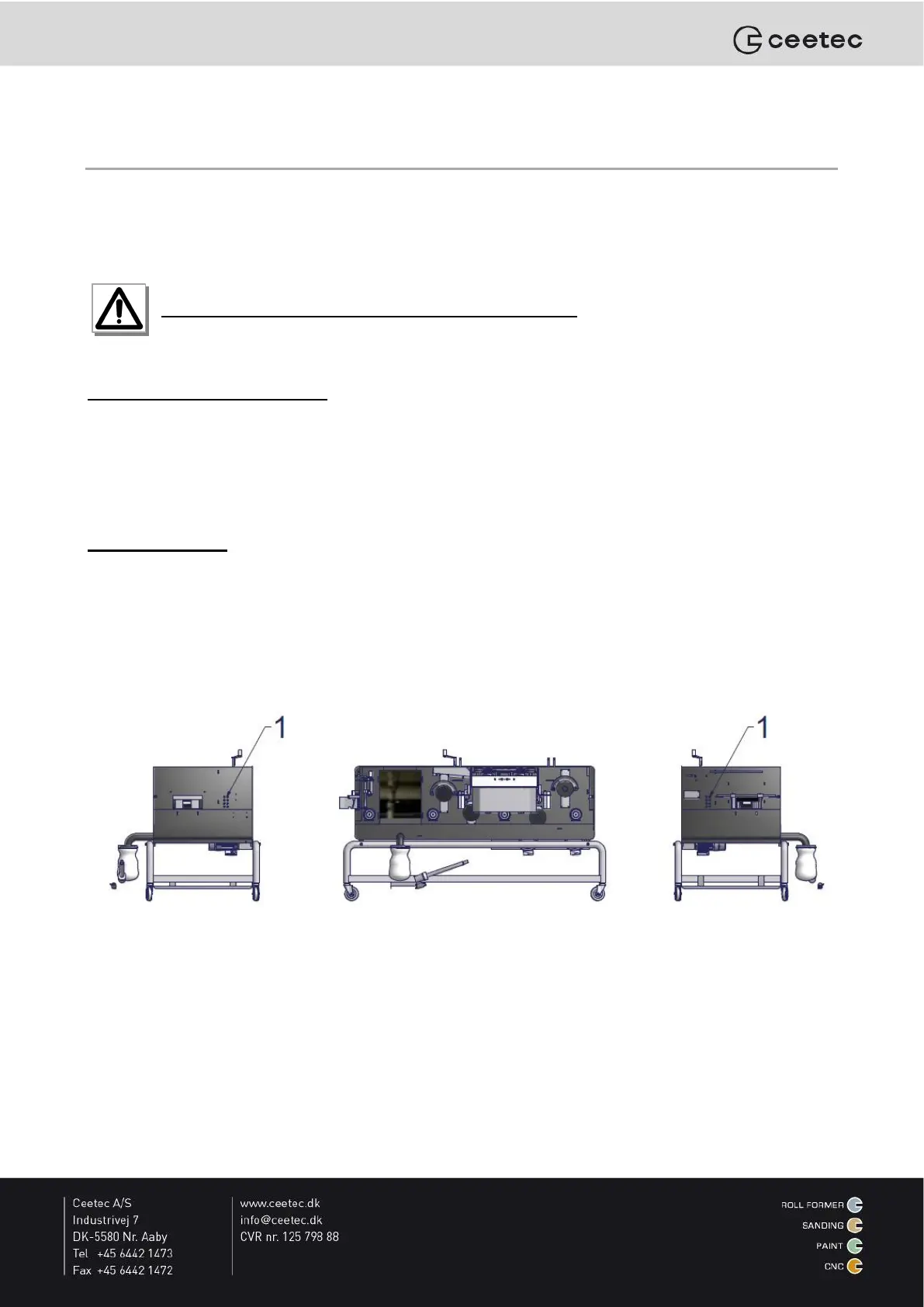

Lubricating nipples (1) on the ends of the machine are greased. Pump 5 times on each lubricating nipple.

These lubricating nipples are for bearings and other moving components for:

· Forward drive

· Horizontal brushes

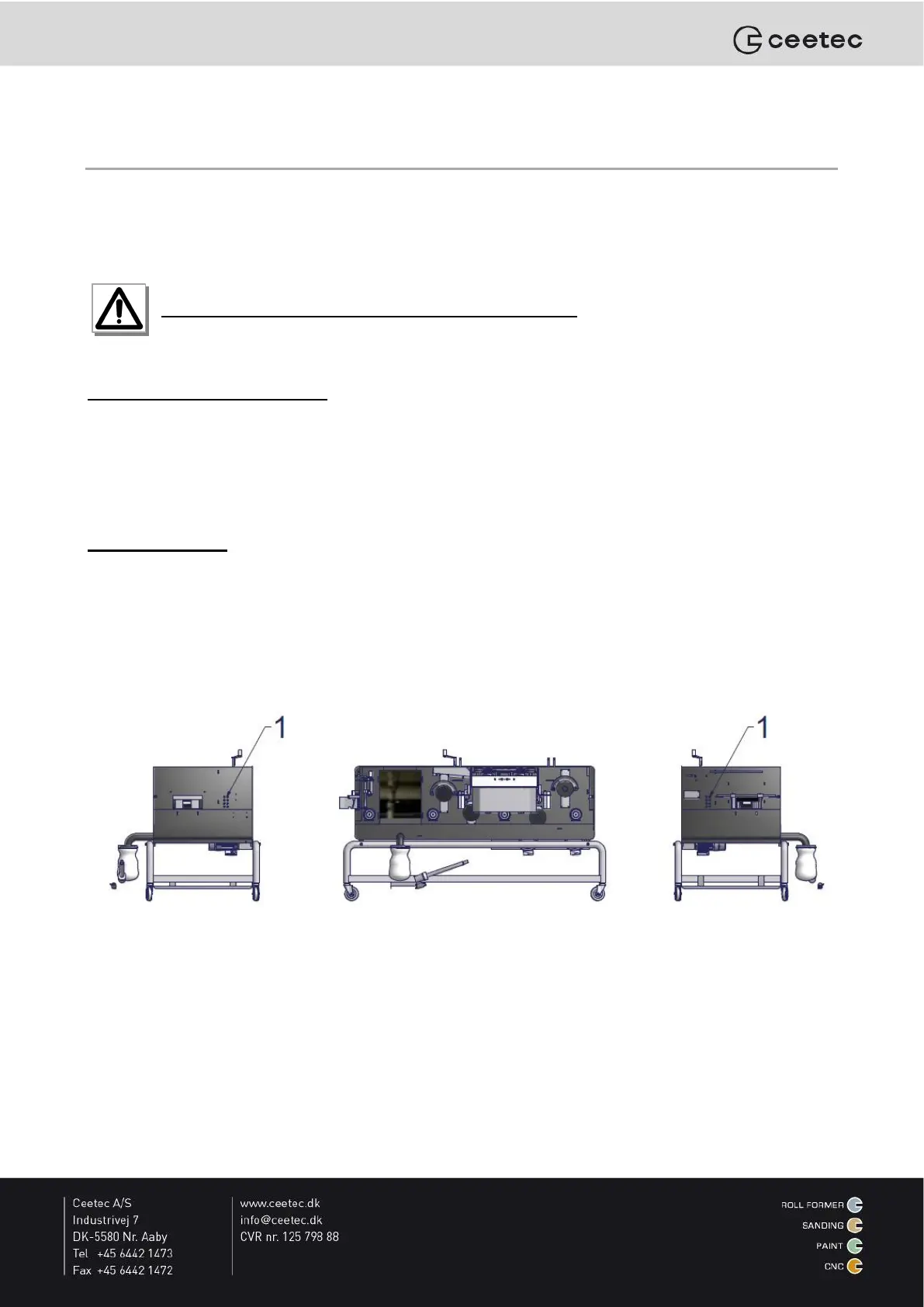

Lubricating nipples for vertical brushes are lubricated the following way:

· Dismount the machine’s fixed lid by loosening the screws

· 8 lubricating nipples (1) on bearings are greased. Pump 5 times on each lubricating nipple

· Remount the machine’s fixed lid

Loading...

Loading...