Page 5 of 45

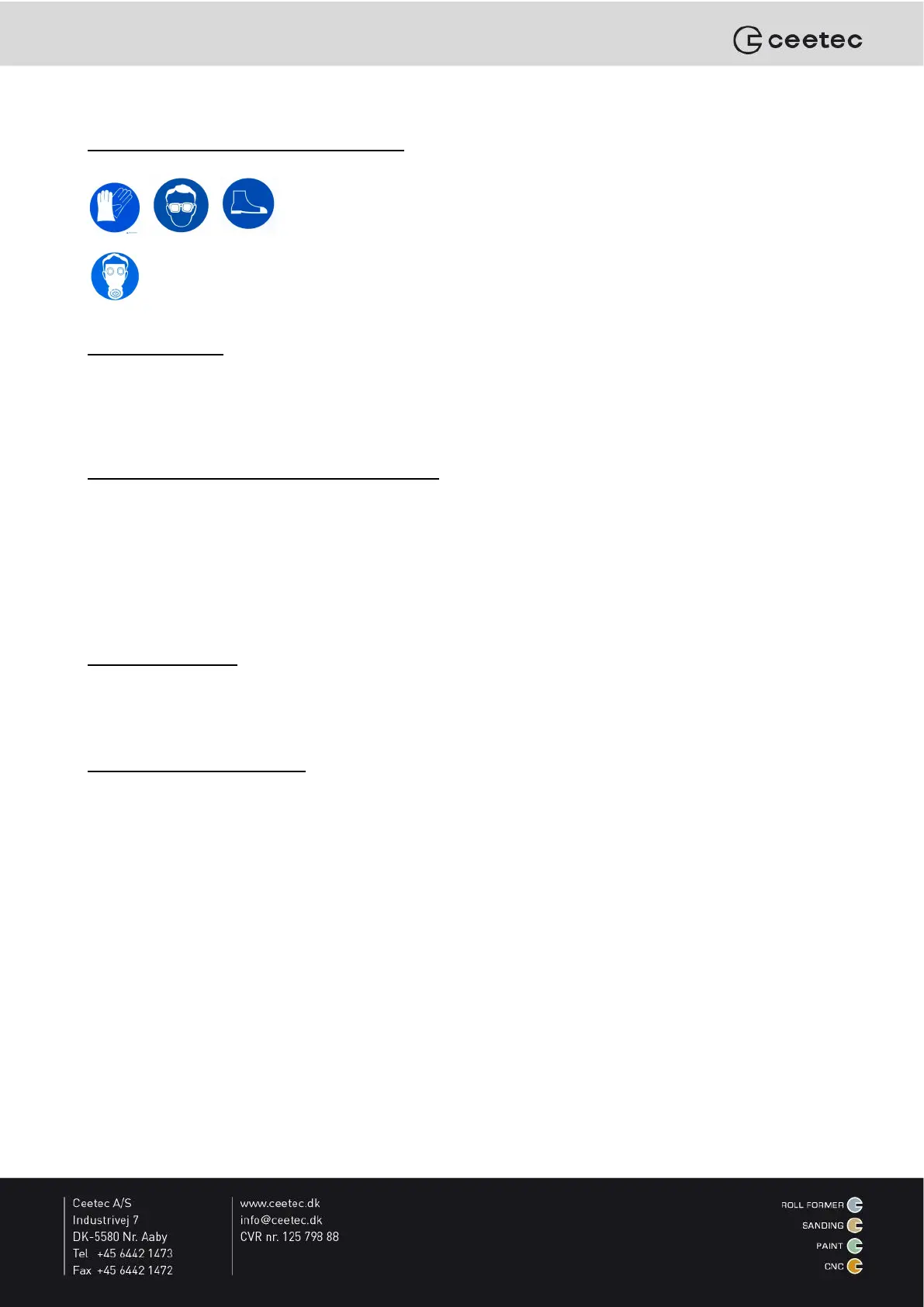

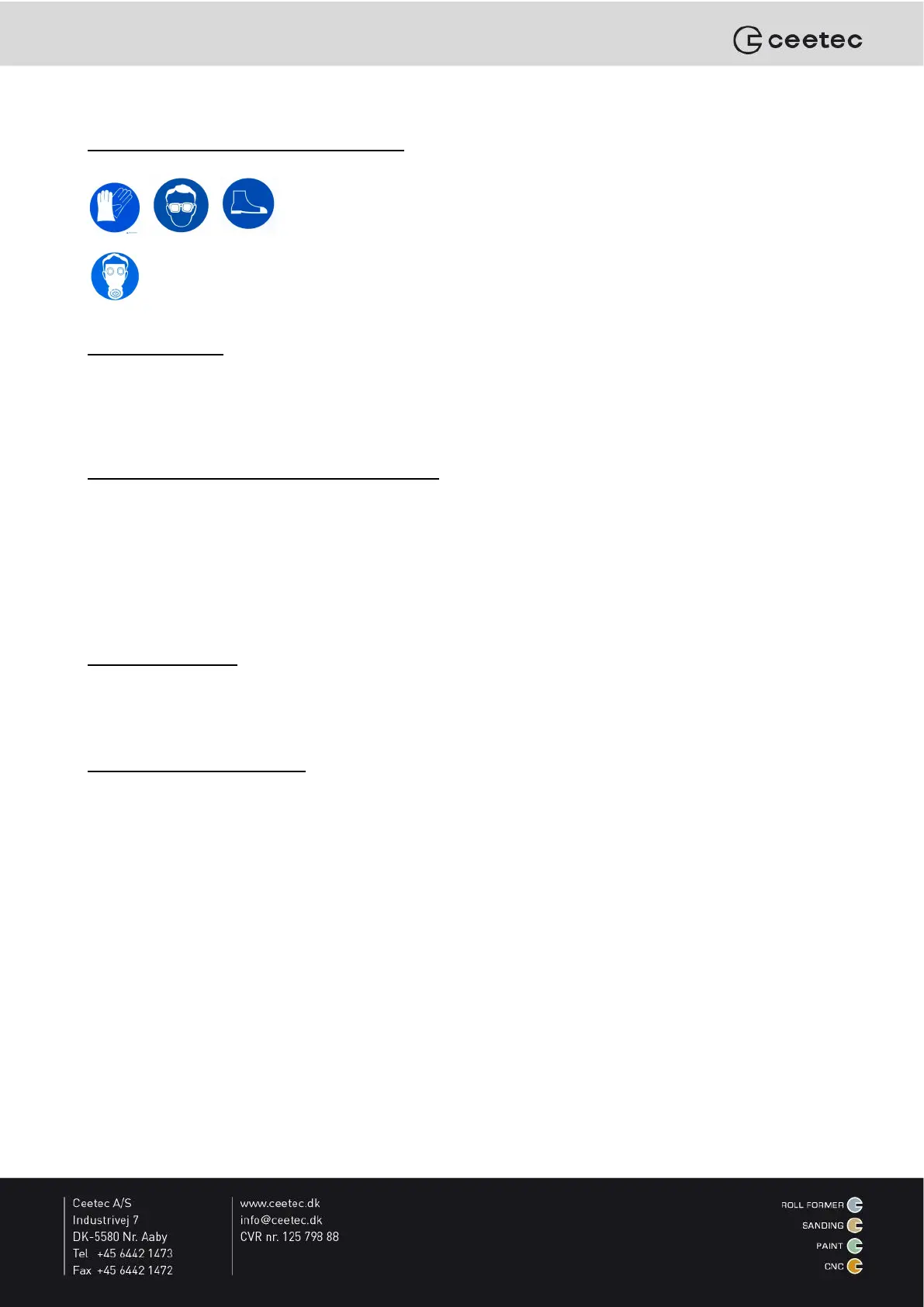

3.3 Personal protective equipment

Necessary safety equipment/personal protective equipment must be used.

Gloves, eye protection and safety shoes are recommended.

Respiratory protection is recommended if there are harmful substances present during processing.

See data sheet from the paint/varnish supplier and follow his directions.

3.4 Clothing

The operator must wear appropriate work clothing. Sleeves must end at the wrists so they do not get caught

in the moving/rotating parts.

3.5 Cleaning, service and maintenance

Do not perform cleaning, service or maintenance work on the machine while it is in use. For all service and

maintenance work is must be ensured that the plant:

- Is free from material (empty)

- The machine is stopped (emergency stop is activated)

- Is disconnected from power supply (plug is removed)

3.6 Screening

Safety screens and equipment must not be overridden or removed from the machine.

3.7 Special conditions

- All screens, grates, covers, safety screening and safety switches must work satisfactorily and be in

place and in order.

- Always keep the machine, work surfaces and the work area clean and tidy.

- Only carry out work with the machine when situated in the machine’s operator places.

- Do not touch and do not attempt to move items when the machine is working.

- If it is necessary to check parts of the machine which are not protected by a grate and/or safety

screens, the machine must be stopped (emergency stop) and the power must be disconnected.

- In case of a shutdown it must be ensured that the plant has stopped completely before attempting to

remedy the error.

- Always follow the supplier user manuals for the wood preservation/paint.

Loading...

Loading...