57Troubleshooting

Troubleshooting

Problems and Possible Solutions

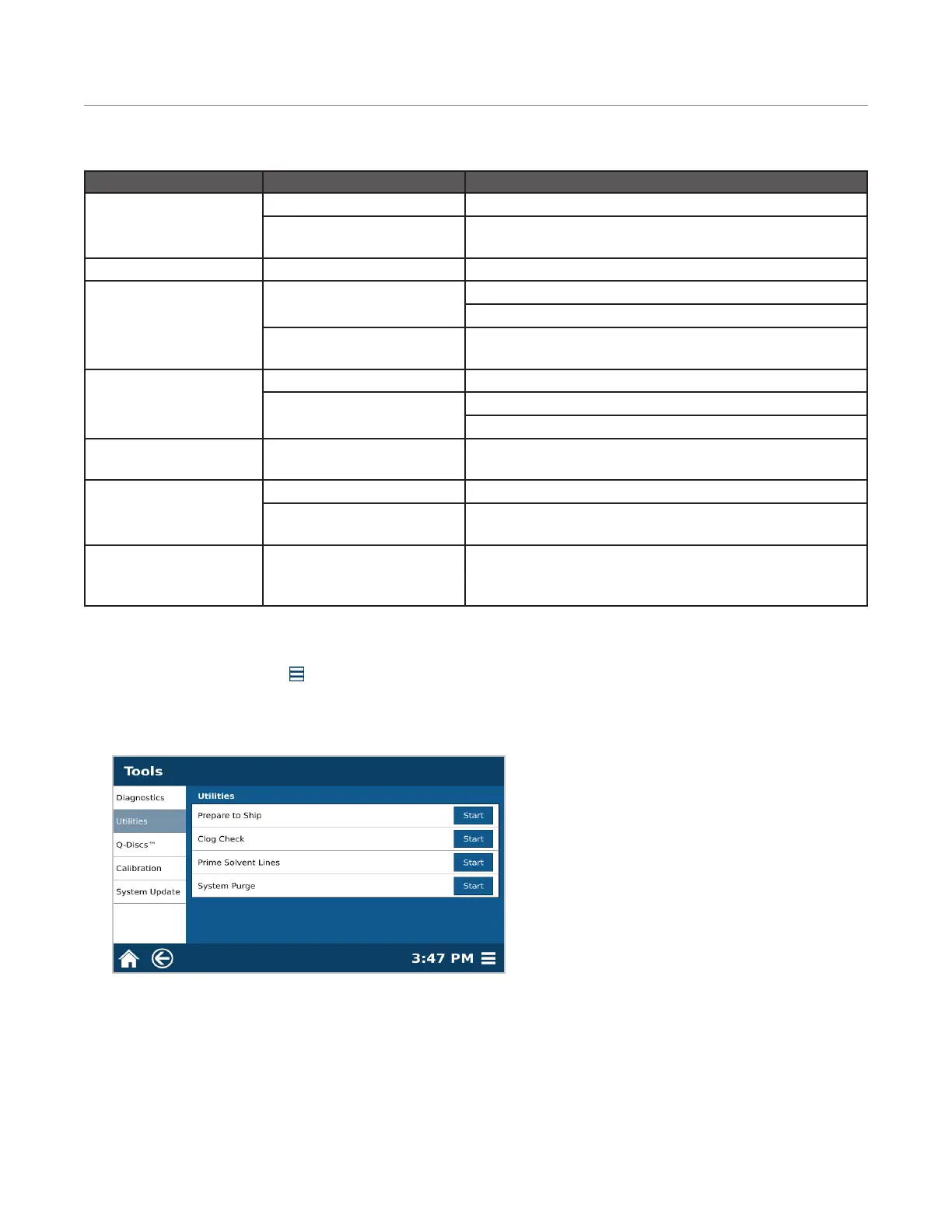

Problems Possible Cause Possible Solutions

Recoveries are low Hold time not long enough Increase hold time by 1:00

Incorrect Temperature Increase temperature by 10 °C or decrease by 10 °C for

temperature sensitive analytes

Water in the extract Wet Sample Increase drying agent

Possible System Clog Slow sample draining Increase pore size of Q-Disc. For cellulose, increase C#

Mix dry samples with sand to disperse sample

Q-Cup(s) overlled Clean the actuator. See “Routine Maintenance” for instructions. See

“Sample Preparation” for preventative measures.

Solvent/Extract Recovery low Solvent Bottle(s) empty Add solvent

Slow sample draining Increase pore size of Q-Disc. For cellulose, increase C#.

Mix dry samples with sand to disperse sample

Particulates in extract Porosity of samples less than

Q-Disc

Decrease pore size of Q-disc. For cellulose, decrease C#

Q-Cup sticking to actuator Q-Cup(s) dirty Clean the Q-Cups. See “ for instruction

Q-Cup(s) overlled Clean the actuator. See “Routine Maintenance” for instructions. See

“Sample Preparation” for preventative measures

Max Pressure Exceeded Pressure generated at

temperature exceeds maximum

system pressure

Decrease method temperature or decrease amount of sample

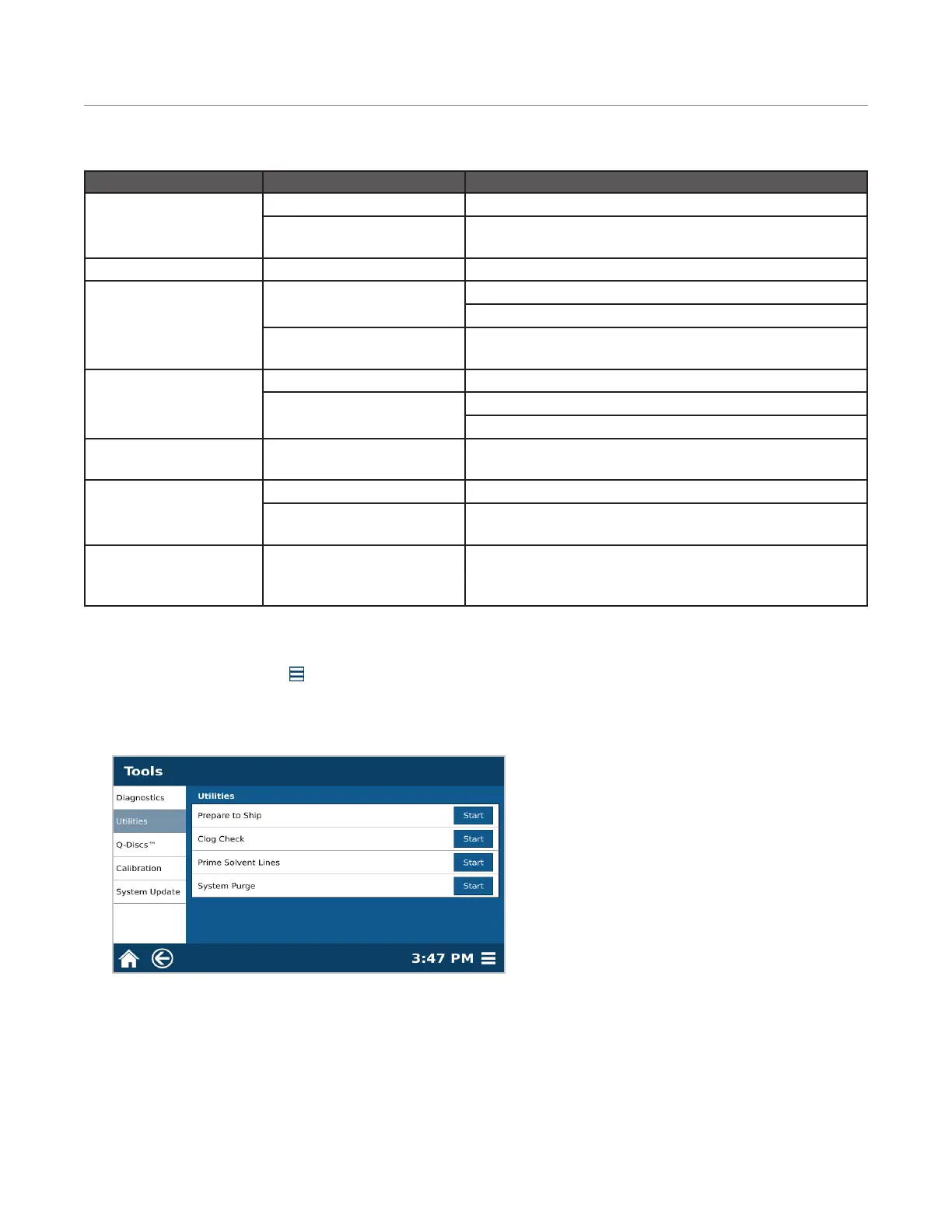

Clog Check

1. Select System Menu icon located in the lower right corner of the screen.

2. Select Tools.

3. Select Utilities.

4. Select Clog Check Start.

5. A screen will appear with a list of locations to check for a clog: Vent, Drain, Cooling coil/dispense needle.

Select “OK” to begin clog check.

Loading...

Loading...