page 22 www.centsys.com

OPERATOR INSTALLATIONSECTION 7

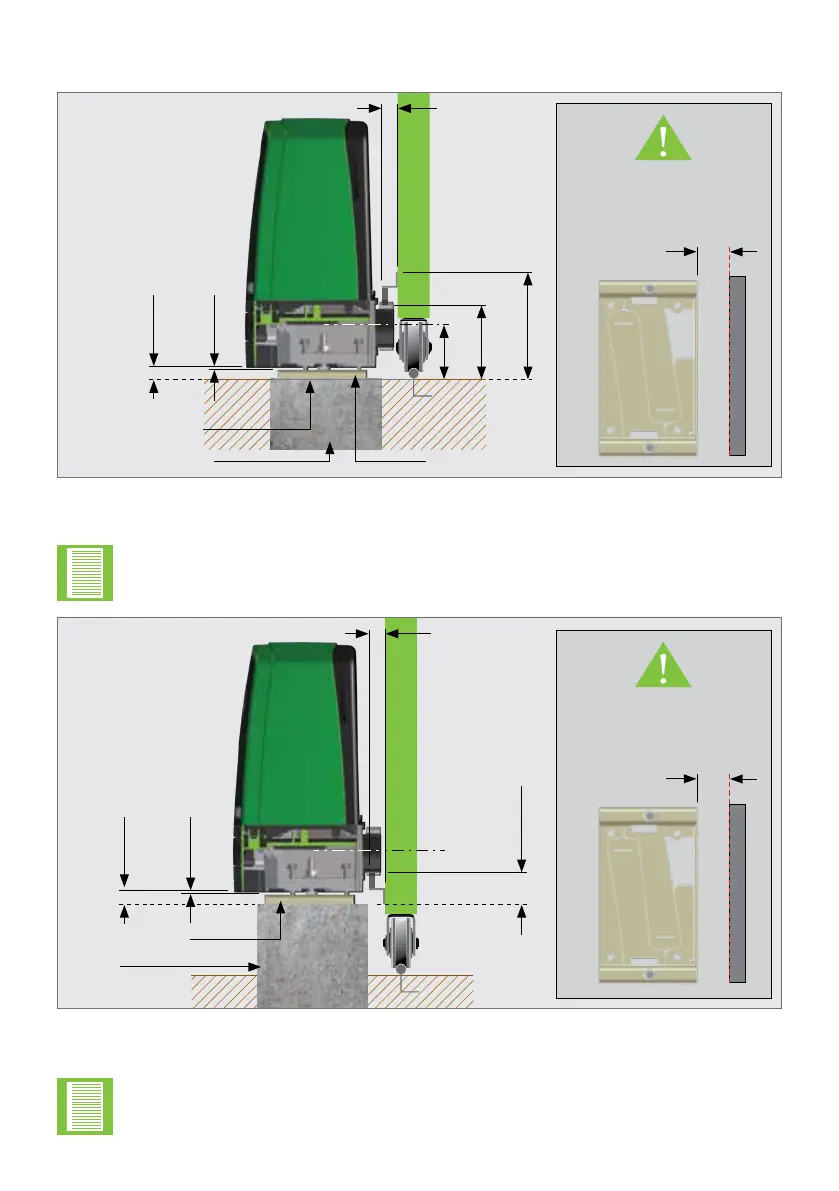

D10 Turbo SMART - Steel Rack

FIGURE 13. STEEL RACK ABOVE PINION - D10 TURBO SMART

1. Includes 3mm clearance required between rack and pinion

2. Distance between bottom of the Foundation Plate and bottom edge of the Rack Tooth

5mm

25mm

91mm

127mm

1,2

182mm

1

25mm

(Typical Steel

Rack Width)

Flat bar welded

to Foundation Plate

and rail

Concrete Foundation

(Recommended to allow

for adjustment)

Minimum space from edge

of Foundation Plate to

reference point of edge that

protrudes the furthest.

(Section 7.1.1.)

Foundation Plate

50mm

The principles of installation on a Steel Rack is to position it in the middle of the

output pinion with the operator fully forward on the slots.

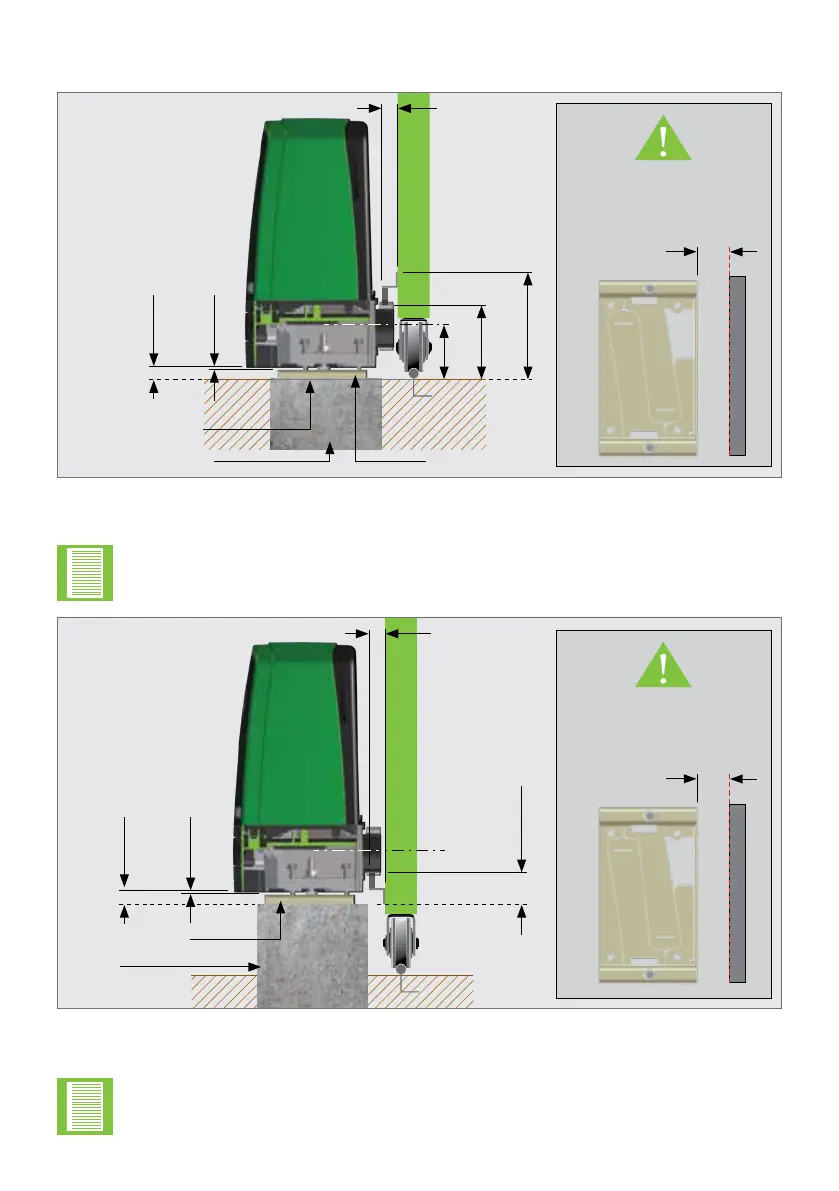

FIGURE 14. STEEL RACK BELOW PINION - D10 TURBO SMART

1. Includes 3mm clearance required between rack and pinion

2. Distance between bottom of the Foundation Plate and top edge of the Rack Tooth

5mm

25mm

25mm

(Typical Steel

Rack Width)

45mm

1,2

Foundation Plate

Raised

Concrete

Foundation

(Recommended to allow

for adjustment)

The principles of installation on a Steel Rack is to position it in the middle of the

output pinion with the operator fully forward on the slots.

Minimum space from edge

of Foundation Plate to

reference point of edge that

protrudes the furthest.

(Section 7.1.1.)

50mm

Loading...

Loading...