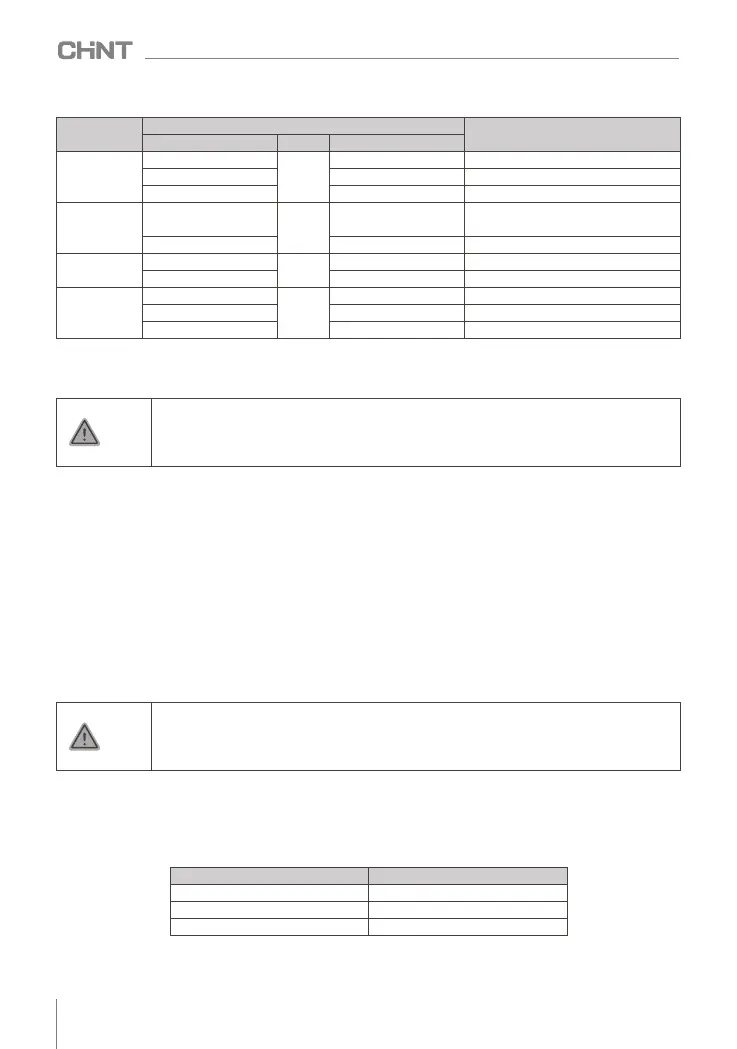

Table 10.1 Daily inspection reminder list

inspection

object

Check essentials

Criterion

check content

cycle

means of inspection

operating

environment

1.Temperature and humidity

at any

time

1. Thermometer , hygrometer

1. (-10~+45)℃, (45~55)℃ derating use

2. Dust, water and drip 2. Visual inspection

2. No trace of water leakage

3. Gas

3. Smell

3. No smell

Inverter

1. Vibration, heat

at any

time

1. Surgical Touch

1. Stable vibration and reasonable fan

temperature

2. Noise 2. Hearing

2. No abnormal sound

motor

1. Fever

at any

time

1. Hand touch

1. There is no abnormality in fever

2. Noise 2. Hearing

2. Even noise

Running state

parameters

1. Output current

at any

time

1. Hearing

1. Within the rated range

2. Output voltage

2. Ammeter

2. Within the rated range

3. Internal temperature

3. Thermometer

3. Temperature rise is less than 35K

10.4 Regular maintenance

According to the use environment, the user can conduct a regular inspection of the inverter every3 months

or 6 months.

General inspection content:

(1) If the control terminal screw is loose, tighten it with a screwdriver;

(2) Whether the main circuit terminals have poor contact, whether there is overheating trace at the copper

bar connection;

(3) Whether the power cables and control cables are damaged, especially whether there are cut marks on

the skin in contact with the metal surface;

(4) Whether the insulating bandages of the power cables have fallen off;

(5) Fully clean the dust on the circuit board and air duct, it is best to use a vacuum cleaner;

(6) For the insulation test of the inverter, all input and output terminals (R, S, T, U, V, W, etc.) , otherwise

there is a danger of damaging the inverter, please use a 500V megohmmeter;

(7) If the insulation test is performed on the motor, the input terminals U, V, W of the motor must be

disassembled from the inverter, and the motor must be tested separately, otherwise the inverter will be

damaged.

Notice

1. Only professionally trained personnel can disassemble parts , perform maintenance and replace

parts.

2. Do not leave metal parts such as screws and washers in the machine, otherwise there is a risk of

damage to the equipment.

10.5 Replacement of Vulnerable Parts of the Frequency Converter

Vulnerable parts of frequency converter mainly include cooling fan and electrolytic capacitor for filtering,

and their service life is closely related to the environment of use and maintenance status. The general life time

is shown in Table 10.2.

Notice

test has been passed before leaving the factory , and the user does not need to perform the withstand

voltage test, otherwise the device will be damaged if the test is not done properly .

2. Replacing the original components in the inverter with components with different models and

electrical parameters may cause damage to the inverter.

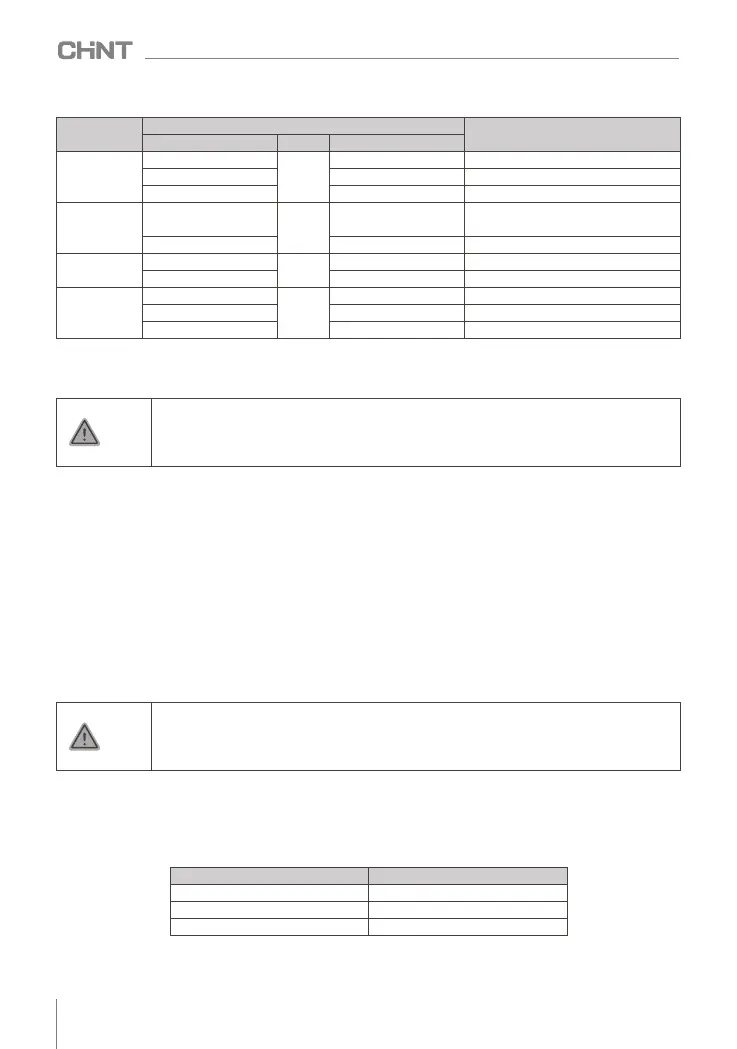

Table 10.2 Component life

Device name

life time

fan

(3~ 4 ) million hours

electrolytic capacitor

(4~ 5 ) million hours

relay

About 100,000 times

Users can determine the replacement period according to the running time.

(1) Cooling fan

076

NVF2G-S Series Inverter User's Guide

Loading...

Loading...