TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

12 Sep 16, 2008

SECTION 4: General Information

4.01 TRANSMIG 225, 255 MIG Power Source, 255 2R Wirefeeder

The TRANSMIG 225, 255 MIG Power Source is a semi-automatic Gas Metal Arc Welder (GMAW-commonly MIG) with either an

integrated or a separate wire feed unit. The Power Source is designed to meet the broad operating needs of the metal

fabrication industry where production efficiency is vital. They are designed to meet the requirements of international standard

EN60974-1 and Australian Standard AS60974-1.

The TRANSMIG 225, 255 MIG Power Source gives excellent performance on mild steel, stainless steel, aluminium, silicon

bronze and some hard facing wires with Argon based shielding gases. The Power Source also gives excellent results on mild

steel using Carbon Dioxide shielding gas.

The TRANSMIG 225, 255 MIG Power Source is supplied as a complete package ready to weld (apart from shielding gas,

electrode wire and Hiderok TM welding helmet). The following instructions detail how to correctly set up the machine and give

guidelines on gaining the best production efficiency from the Power Source. Please read these instructions thoroughly before

using your welder.

4.02 User Responsibility

This equipment will perform as per the information contained herein when installed, operated, maintained and repaired in

accordance with the instructions provided. This equipment must be checked periodically. Defective equipment (including

welding leads) should not be used. Parts that are broken, missing, plainly worn, distorted or contaminated, should be replaced

immediately. Should such repairs or replacements become necessary, it is recommended that such repairs be carried out by

appropriately qualified persons approved by CIGWELD. Advice in this regard can be obtained by contacting accredited

CIGWELD Distributor.

This equipment or any of its parts should not be altered from standard specification without prior written approval of CIGWELD.

The user of this equipment shall have the sole responsibility for any malfunction which results from improper use or unauthorised

modification from standard specification, faulty maintenance, damage or improper repair by anyone other than appropriately

qualified persons approved by CIGWELD.

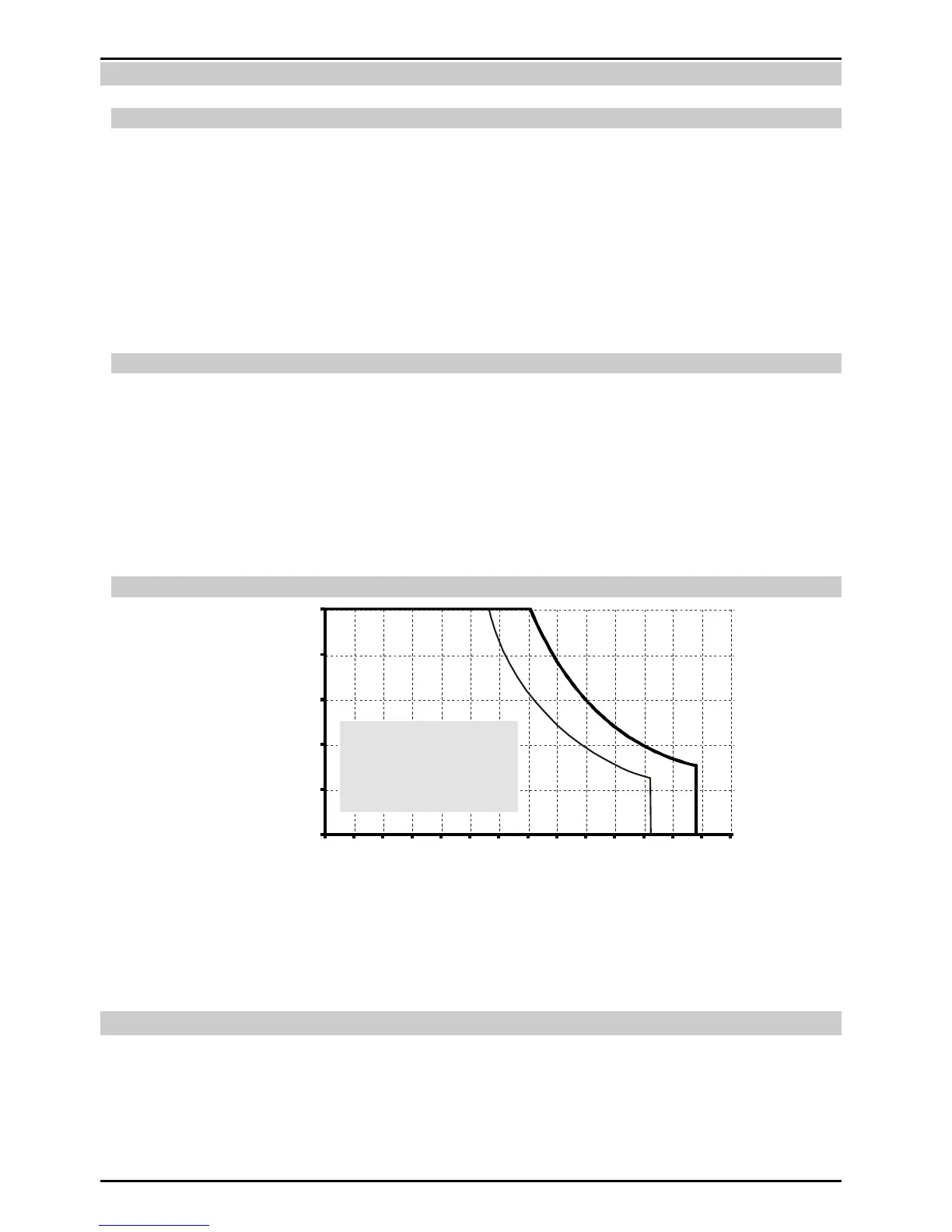

4.03 Duty Cycle

The rated duty cycle of a Welding Power Source, is a statement of the time it may be operated at its rated welding current output

without exceeding the temperature limits of the insulation of the component parts. To explain the 10 minute duty cycle period the

following example is used. Suppose a Welding Power Source is designed to operate at a 30% duty cycle, 255 amperes at 26.5

volts. This means that it has been designed and built to provide the rated amperage (255A) for 3 minutes, i.e. arc welding time,

out of every 10 minute period (30% of 10 minutes is 3 minutes). During the other 7 minutes of the 10 minute period the Welding

Power Source must idle and allowed to cool. The thermal cutout will operate if the duty cycle is exceeded.

SECTION 5: Safe Practices For The Use Of Welding Equipment

In many situations the “striking” voltage can be hazardous. Any person touching simultaneously the electrode lead/terminal and the work

lead/terminal may receive a serious electrical shock. Additional precautions must be exercised where two Welding Power Sources are

being used close to each other because, under certain conditions, the voltages between the welding terminals of the two Welding Power

Sources could be two times the specified open circuit voltage.

It is essential that the Welding Power Source is correctly installed, if necessary, by a qualified electrician and maintained in sound

mechanical and electrical condition. It is also important that the Welding Power Source be switched off when not in use.

Loading...

Loading...