TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 13

5.01 Precautions to be Taken by Operators

Whenever practicable, all parts of the welding circuit should be isolated from earth and other conducting material and under

no circumstances should any earthing conductor of the electrical installation be used in place of the work lead.

The Mains supply voltage should be switched off before connecting or disconnecting welding leads. Welding lead

connections must have clean contact surfaces and must be securely tightened. Poor connections will result in overheating

and loss of welding current. All parts of the welding circuit, including the return paths, are to be considered electrically alive,

so the operator must ensure that no part of the body is placed in such a position that it will provide a path for an electric

current.

Welding operators should avoid direct contact with the work to be welded or against any metal in contact with the work.

When this cannot be avoided the operator must not touch any exposed portion of the electrode holder with any part of the

body. Should this occur, the operator will risk completing the electrical circuit through the body.

When welding in confined spaces, where reasonable movement is restricted, particular care must be taken to ensure that the

area is well ventilated and the operator is under constant observation by a person who can immediately switch off the power

and give assistance in an emergency.

The flux covering of an electrode cannot be assumed to provide effective insulation, consequently an insulating glove must

be worn when placing an electrode into its holder, or should it be necessary to handle an electrode once it is in contact with

its holder.

During pauses between welding runs, electrode holders, TIG torches and MIG torches should be so placed that they cannot

make electrical contact with persons or conductive objects.

The welding leads, both the electrode lead, TIG torch lead or MIG torch lead and the work lead, must be protected from

damage. Damaged leads must not be used.

Keep combustible materials away from the welding area. Have a suitable fire extinguisher handy.

Do not stand on damp ground when welding.

5.02 Personal Protection

The radiation from an electric arc during the welding process can seriously harm eyes and skin. It is essential that the following

precautions be taken:

Gloves should be flameproof gauntlet type to protect hands and wrists from heat burns and harmful radiations. They should

be kept dry and in good repair.

Protective clothing must protect the operator from burns, spatter and harmful radiation. Woollen clothing is preferable to

cotton because of its greater flame resistance. Clothing should be free from oil or grease. Wear leggings and spats to

protect the lower portion of the legs and to prevent slag and molten metal from falling into boots or shoes.

Welding Faceshield

It is a requirement to use a welding Faceshield, complying to a relevant standard, when electric arc welding. Use a welding

Faceshield in serviceable condition and fitted with an eye filter lens to safely reduce harmful radiation from the arc as per

Table 1.

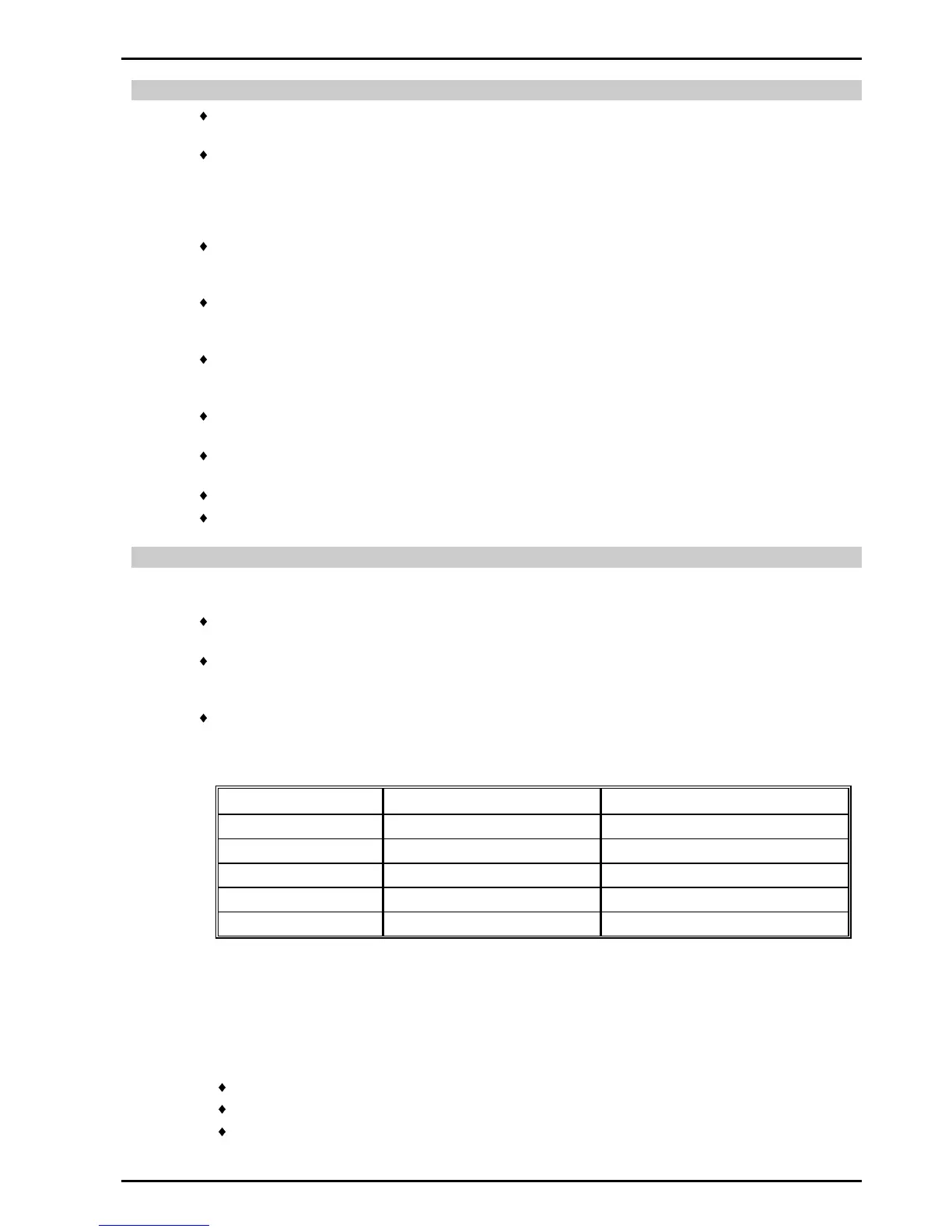

Table 1 - Filter lens size verses welding current/electrode size

Protective filter lenses are provided to reduce the intensity of radiation entering the eye thus filtering out harmful infra-red,

ultra-violet radiation and a percentage of the visible light. Such filter lenses are incorporated within welding handshields. To

prevent damage to the filter lenses from molten or hard particles an additional hard clear glass or special plastic external

cover lens is provided. This cover lens should always be kept in place and replaced before the damage impairs your vision

while welding.

Notes:

Recognised standards for recommended practices for occupational eye protection include AS/ANZ 1336 and EN 175.

For maximum possible protection, the use of full helmet equipment is recommended.

The indicated filter lens shade numbers are minimum. If any discomfort is felt, higher shade numbers (i.e. darker filters)

should be used.

Loading...

Loading...