TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 17

8.03 Ventilation

Since the inhalation of welding fumes can be harmful, ensure that the welding area is effectively ventilated.

8.04 Mains Supply Voltage Requirements

The Mains supply voltage should be within 10% of the rated Mains supply voltage. Too low a voltage may cause poor welding

performance. Too high a supply voltage will cause components to overheat and possibly fail.

The Welding Power Source must be:

Correctly installed, if necessary, by a qualified electrician.

Correctly earthed (electrically) in accordance with local regulations.

Connected to the correct size power point and fuse for each Power Source as per the Specifications on page 15.

The TRANSMIG 225, 255 MIG Power Source is supplied with a 15 Amp input lead.

The TRANSMIG 225, 255 MIG Power Source is factory connected for 240 VAC supply voltage:

The TRANSMIG 225, 255 MIG Power Source is suitable for the following Mains supply voltages:

The following Mains Current Circuit recommendations are required to obtain the maximum welding current and duty cycle from

these welding products:

Table 4 – Supply Requirements

8.05 Mains Supply Voltage Requirements

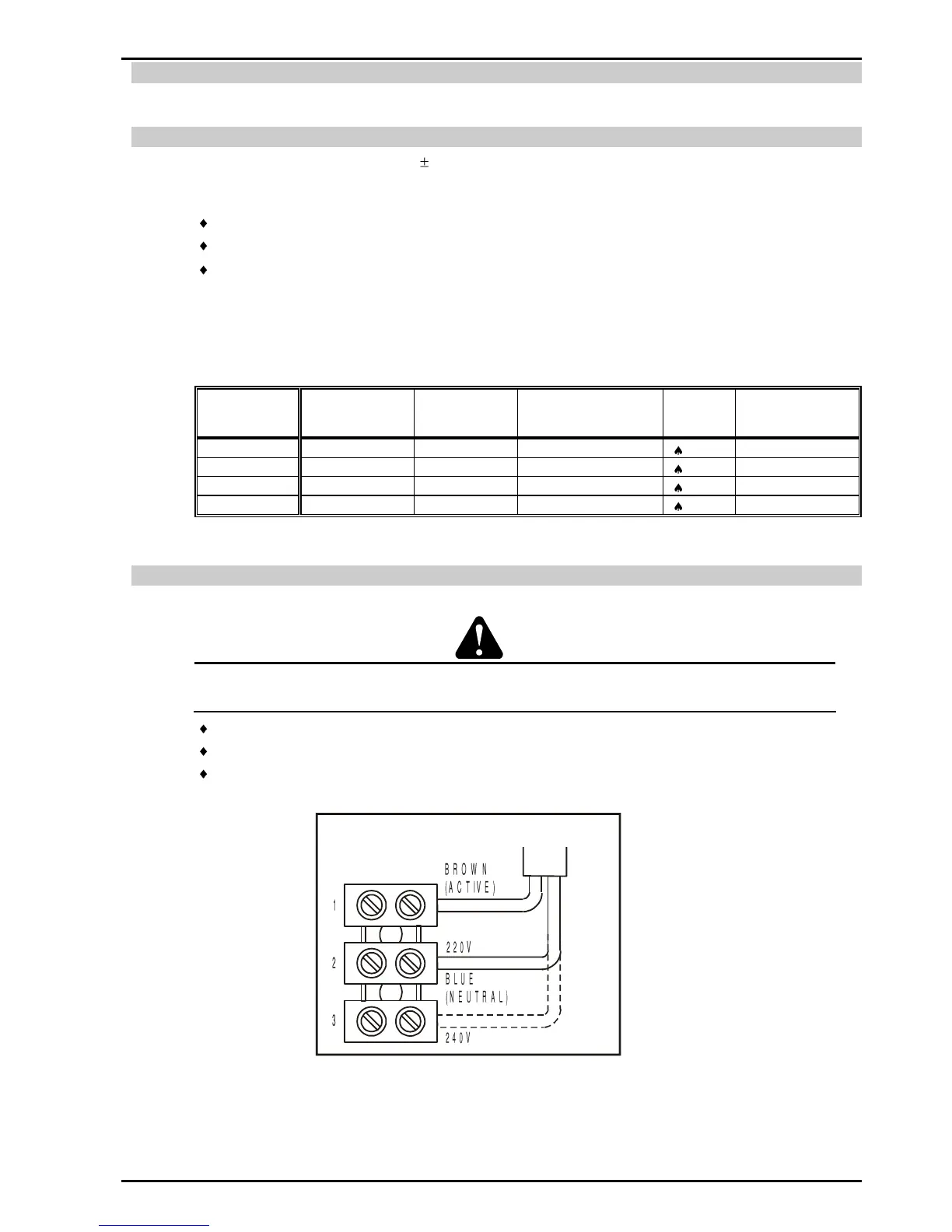

The TRANSMIG 225, 255 can be rewired to operate from a 220VAC mains supply voltage.

WARNING 6

CIGWELD ADVISES THAT A QUALIFIED ELECTRICAL TRADESPERSON REWIRE YOUR TRANSMIG 225, 255

FOR 220VAC OPERATION

Disconnect the TRANSMIG 225, 255 from the mains supply

Disconnect NEUTRAL (Blue) from terminal 2 and reconnect it to terminal 3 on the supply cable terminal block

The TRANSMIG 225, 255 is now ready for operation at 220VAC mains supply voltage

Loading...

Loading...